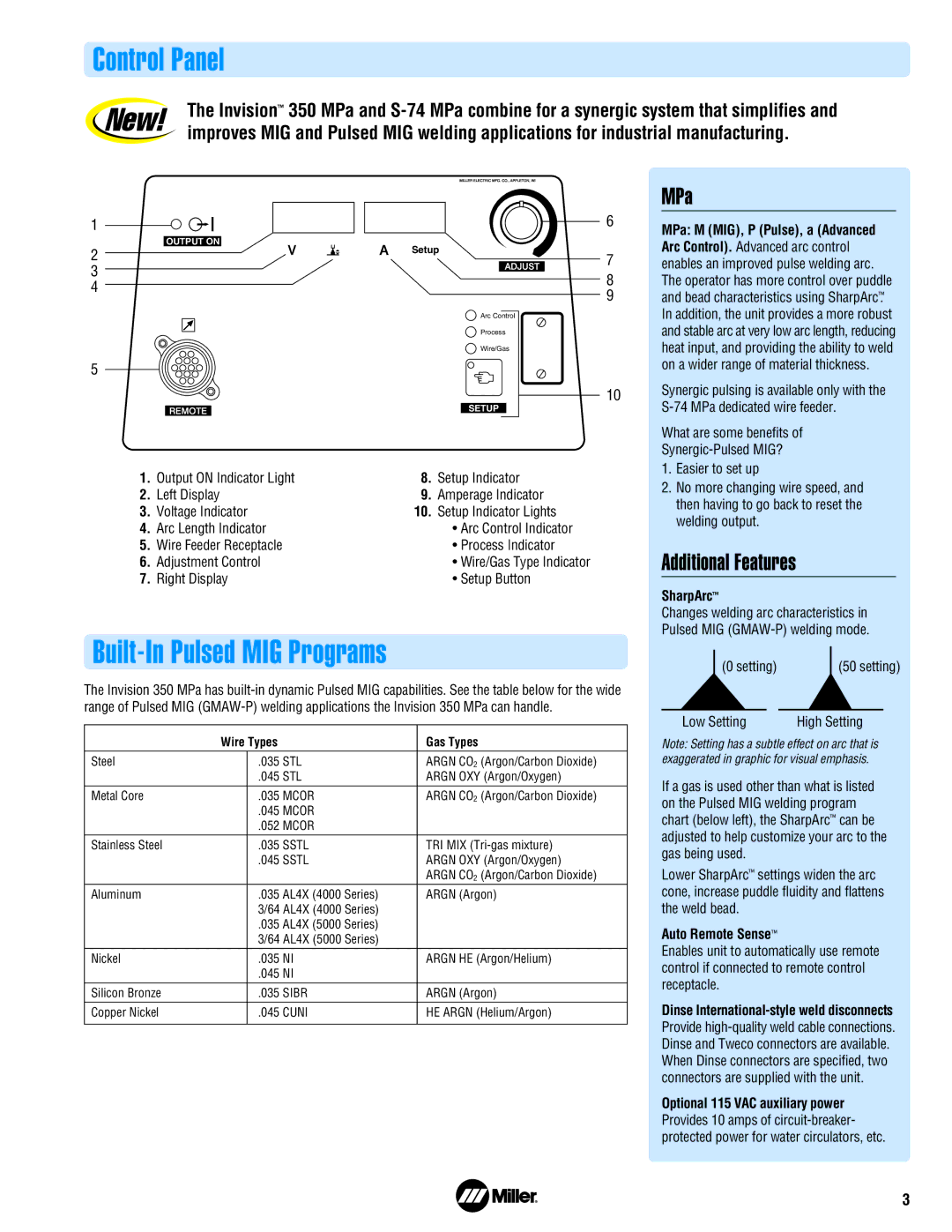

Control Panel

The Invision™ 350 MPa and

1

6

MPa

MPa: M (MIG), P (Pulse), a (Advanced

OUTPUT ON

2

3

4

5

1.Output ON Indicator Light

2.Left Display

3.Voltage Indicator

4.Arc Length Indicator

5.Wire Feeder Receptacle

6.Adjustment Control

7.Right Display

Setup | Arc Control). Advanced arc control | ||||

7 | enables an improved pulse welding arc. | ||||

8 | The operator has more control over puddle | ||||

9 | ™ | ||||

and bead characteristics using SharpArc . | |||||

|

|

| In addition, the unit provides a more robust | ||

Arc Control |

|

| |||

Process |

| and stable arc at very low arc length, reducing | |||

Wire/Gas |

| heat input, and providing the ability to weld | |||

|

|

|

| on a wider range of material thickness. | |

|

|

| 10 | Synergic pulsing is available only with the | |

| |||||

SETUP |

| ||||

|

|

|

| What are some benefits of | |

|

|

|

| ||

8. Setup Indicator | 1. Easier to set up | ||||

2. No more changing wire speed, and | |||||

9. Amperage Indicator | |||||

then having to go back to reset the | |||||

10. Setup Indicator Lights | |||||

welding output. | |||||

• Arc Control Indicator | |||||

| |||||

• Process Indicator | Additional Features | ||||

• Wire/Gas Type Indicator | |||||

• Setup Button |

| ||||

SharpArc™ | |||||

|

|

|

| ||

|

|

|

| Changes welding arc characteristics in | |

|

|

|

| Pulsed MIG | |

Built-In Pulsed MIG Programs

The Invision 350 MPa has

| Wire Types |

| Gas Types | |

Steel |

| .035 | STL | ARGN CO2 (Argon/Carbon Dioxide) |

|

| .045 | STL | ARGN OXY (Argon/Oxygen) |

Metal Core |

| .035 | MCOR | ARGN CO2 (Argon/Carbon Dioxide) |

|

| .045 MCOR |

| |

|

| .052 MCOR |

| |

Stainless Steel |

| .035 | SSTL | TRI MIX |

|

| .045 | SSTL | ARGN OXY (Argon/Oxygen) |

|

|

|

| ARGN CO2 (Argon/Carbon Dioxide) |

Aluminum |

| .035 | AL4X (4000 Series) | ARGN (Argon) |

|

| 3/64 AL4X (4000 Series) |

| |

|

| .035 | AL4X (5000 Series) |

|

|

| 3/64 AL4X (5000 Series) |

| |

Nickel |

| .035 | NI | ARGN HE (Argon/Helium) |

|

| .045 | NI |

|

Silicon Bronze |

| .035 | SIBR | ARGN (Argon) |

|

|

|

|

|

Copper Nickel |

| .045 | CUNI | HE ARGN (Helium/Argon) |

|

|

|

|

|

| (0 setting) |

| (50 setting) | ||

|

| ||||

|

|

|

|

|

|

Low Setting | High Setting | ||||

Note: Setting has a subtle effect on arc that is exaggerated in graphic for visual emphasis.

If a gas is used other than what is listed on the Pulsed MIG welding program chart (below left), the SharpArc™ can be adjusted to help customize your arc to the gas being used.

Lower SharpArc™ settings widen the arc cone, increase puddle fluidity and flattens the weld bead.

Auto Remote Sense™

Enables unit to automatically use remote control if connected to remote control receptacle.

Dinse

Optional 115 VAC auxiliary power Provides 10 amps of

3