M-25 specifications

The Miller Electric M-25 is a high-performance MIG welding gun renowned for its durability, efficiency, and versatility in various welding applications. This tool is widely used in manufacturing, automotive, and construction industries due to its advanced features and reliable performance.One of the main characteristics of the M-25 is its lightweight design, which enhances maneuverability without compromising on strength. Weighing in at a mere 2.5 pounds, this welding gun is crafted with a robust construction that ensures it can withstand the rigors of daily use while remaining comfortable for extended welding sessions. The ergonomic grip is designed to provide added comfort, reducing operator fatigue.

The M-25 features a unique trigger design that promotes a smooth and consistent arc, which is critical for achieving high-quality welds. The trigger is easy to operate, allowing welders to maintain control and precision. Additionally, the M-25 is compatible with various wire sizes and types, making it versatile for a multitude of welding applications. From thin gauge metals to heavier materials, the M-25 delivers consistent results.

Another significant advantage of the Miller Electric M-25 is its integrated cooling system. This system enhances the gun's performance by extending its lifespan and reducing downtime for maintenance. The cooling capability is particularly beneficial during prolonged welding sessions, as it helps prevent overheating. This ensures that the welder can work effectively without interruptions, a crucial factor in high-pressure environments.

The M-25 also incorporates advanced technologies such as Auto-Set feature compatibility. This technology allows welders to set the machine parameters automatically based on the material thickness and the wire type used. This feature simplifies the welding process, making it accessible for both novice and experienced welders.

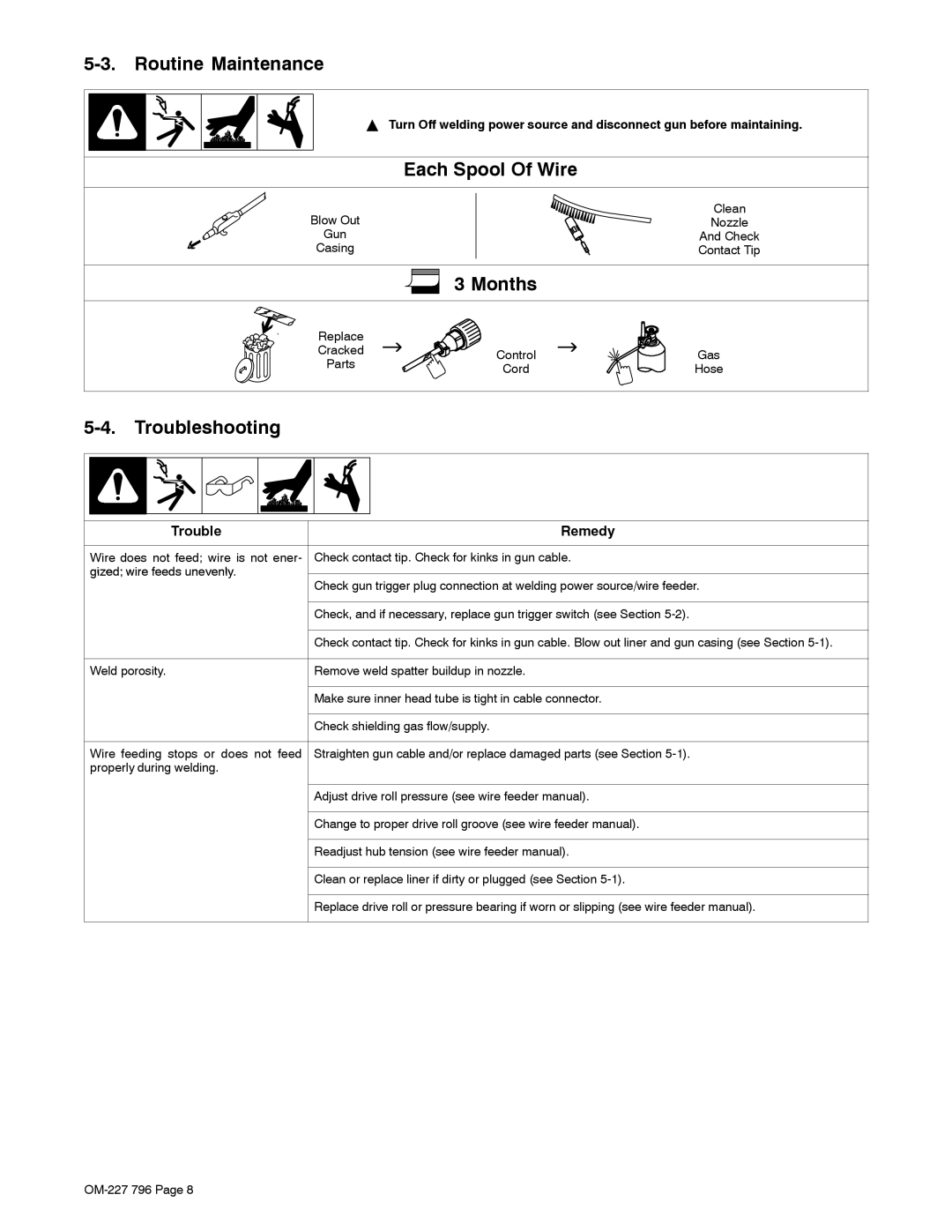

Furthermore, the M-25 supports quick-change liners and nozzles, which significantly aids in maintaining the gun and allows users to swap out parts with minimal effort. This ease of maintenance ensures that the welding gun remains in optimal operating condition, enhancing productivity.

In conclusion, the Miller Electric M-25 welding gun stands out in the market due to its combination of lightweight design, advanced cooling technology, easy maintenance features, and impressive versatility. Whether used in heavy industrial applications or lighter manufacturing tasks, the M-25 remains a reliable choice for welders seeking performance and durability. Its thoughtful features and user-friendly design make it an essential tool for professionals in the field.