SECTION 1 − SAFETY PRECAUTIONS AND SIGNAL WORDS

1-1. GENERAL INFORMATION AND SAFETY A. General

Information presented in this manual and on various la- bels, tags, and plates on the unit pertains to equipment design, installation, operation, maintenance, and troubleshooting which should be read, understood, and followed for the safe and effective use of this equipment.

The nameplate of this unit uses international symbols for labeling the front panel controls. The symbols also appear at the appropriate section in the text.

B. Safety

The installation, operation, maintenance, and trouble- shooting of arc welding equipment requires practices and procedures which ensure personal safety and the safety of others. Therefore, this equipment is to be in- stalled, operated, and maintained only by qualified per- sons in accordance with this manual and all applicable codes such as, but not limited to, those listed at the end of Section 1 − Safety Rules For Operation Of Arc Weld- ing Power Source.

1-2. SAFETY ALERT SYMBOL AND SIGNAL WORDS

The following safety alert symbol and signal words are used throughout this manual to call attention to and

identify different levels of hazard and special instruc- tions.

This safety alert symbol is used with the signal words WARNING and CAUTION to call atten- tion to the safety statements.

![]() WARNING statements identify procedures or practices which must be followed to avoid seri-

WARNING statements identify procedures or practices which must be followed to avoid seri- ![]()

![]()

![]() ous personal injury or loss of life.

ous personal injury or loss of life.

![]() CAUTION statements identify procedures or practices which must be followed to avoid minor

CAUTION statements identify procedures or practices which must be followed to avoid minor ![]()

![]()

![]() personal injury or damage to this equipment.

personal injury or damage to this equipment.

IMPORTANT statements identify special instructions necessary for the most efficient operation of this equip- ment.

1-3. DESCRIPTION

Remote Hand Controls are designed for use as remote amperage or voltage controls in conjunction with a weld- ing power source or welding generator having electric control facilities. Remote Hand Controls with the letters GD displayed in the model description are designed for use with welding generators only.

SECTION 2 − INSTALLATION

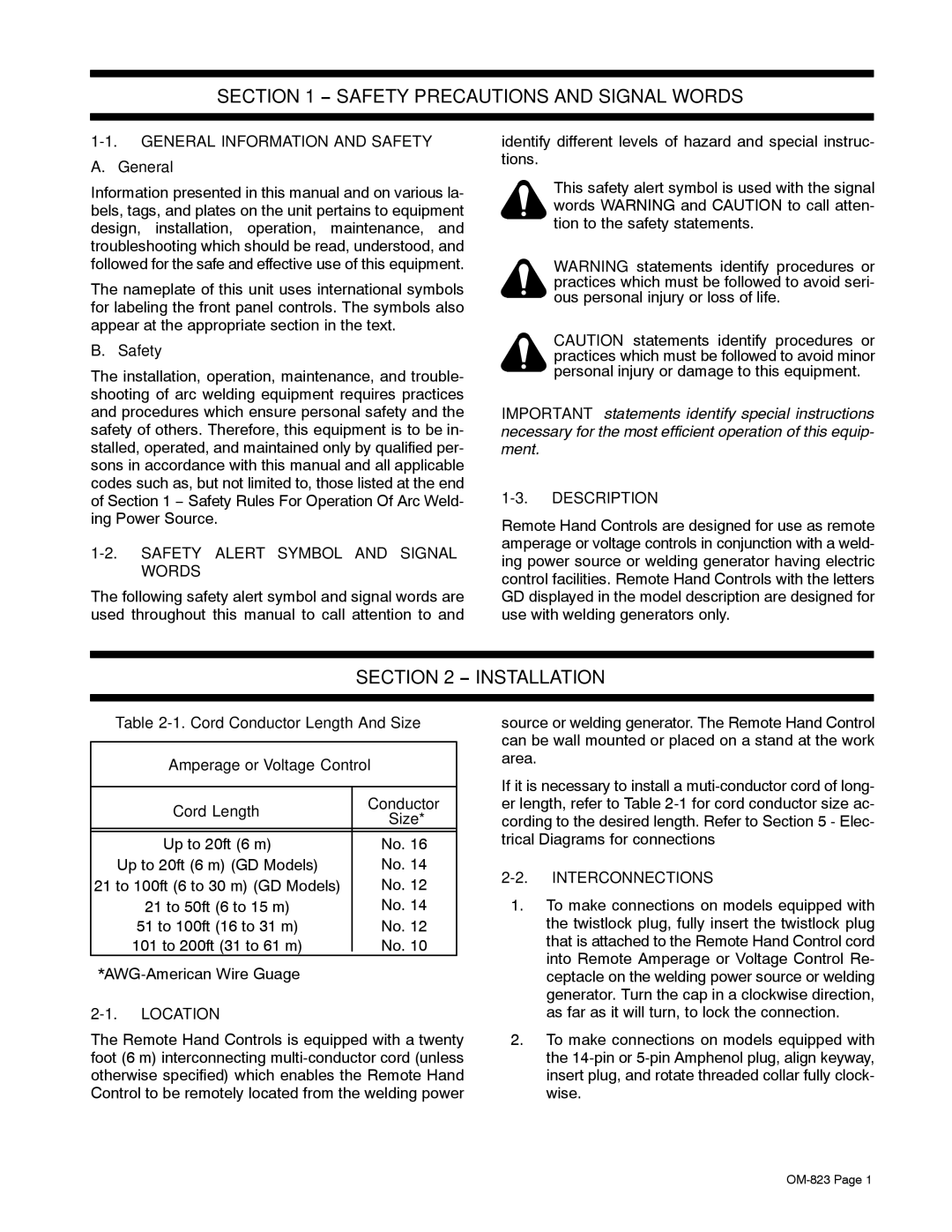

Table

Amperage or Voltage Control

Cord Length | Conductor | ||

Size* | |||

| |||

|

|

| |

Up to 20ft (6 m) | No. 16 | ||

Up to 20ft (6 m) (GD Models) | No. 14 | ||

21 to 100ft (6 to 30 m) (GD Models) | No. 12 | ||

21 to 50ft (6 to 15 m) | No. 14 | ||

51 to 100ft (16 to 31 m) | No. 12 | ||

101 to 200ft (31 to 61 m) | No. 10 | ||

2-1. LOCATION

The Remote Hand Controls is equipped with a twenty foot (6 m) interconnecting

source or welding generator. The Remote Hand Control can be wall mounted or placed on a stand at the work area.

If it is necessary to install a

2-2. INTERCONNECTIONS

1.To make connections on models equipped with the twistlock plug, fully insert the twistlock plug that is attached to the Remote Hand Control cord into Remote Amperage or Voltage Control Re- ceptacle on the welding power source or welding generator. Turn the cap in a clockwise direction, as far as it will turn, to lock the connection.

2.To make connections on models equipped with the