TOOL ASSEMBLY

WARNING

To reduce the risk of injury, always unplug tool before attaching or removing accessories or making adjustments. Use only specifically recommended accessories. Others may be hazardous.

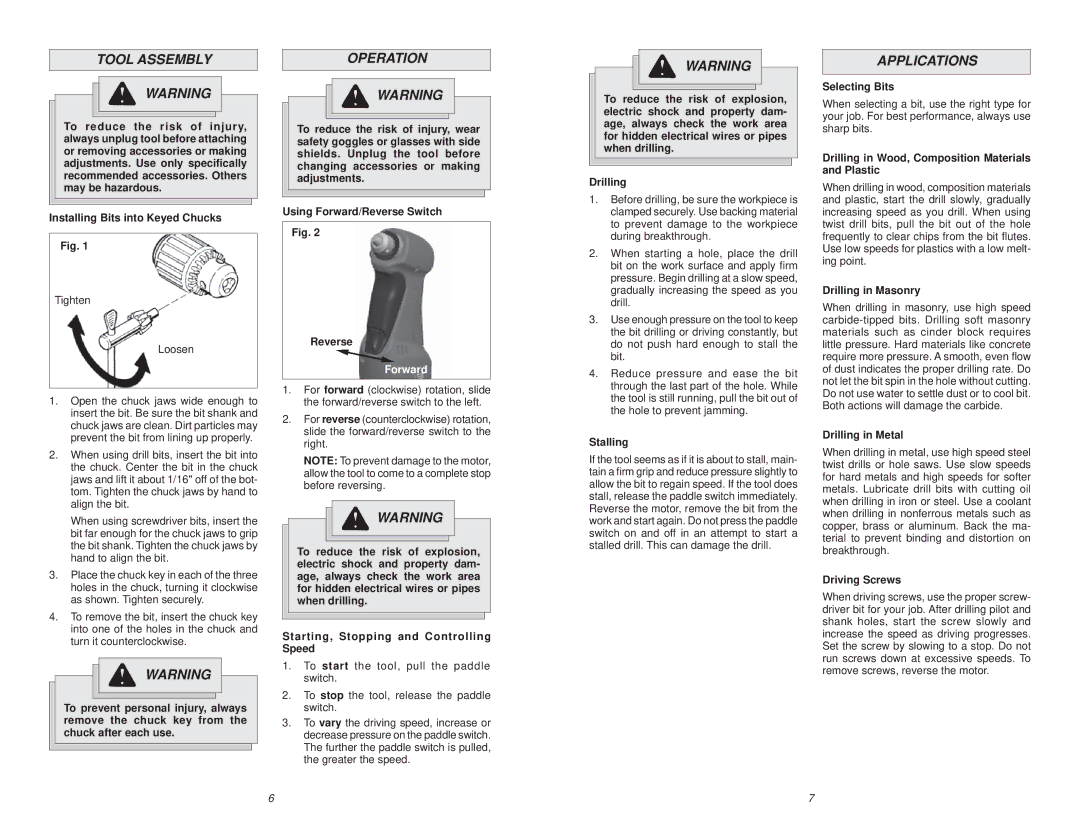

Installing Bits into Keyed Chucks

Fig. 1

Tighten

Loosen

1.Open the chuck jaws wide enough to insert the bit. Be sure the bit shank and chuck jaws are clean. Dirt particles may prevent the bit from lining up properly.

2.When using drill bits, insert the bit into the chuck. Center the bit in the chuck jaws and lift it about 1/16" off of the bot- tom. Tighten the chuck jaws by hand to align the bit.

When using screwdriver bits, insert the bit far enough for the chuck jaws to grip the bit shank. Tighten the chuck jaws by hand to align the bit.

3.Place the chuck key in each of the three holes in the chuck, turning it clockwise as shown. Tighten securely.

4.To remove the bit, insert the chuck key into one of the holes in the chuck and turn it counterclockwise.

WARNING

To prevent personal injury, always remove the chuck key from the chuck after each use.

OPERATION

![]() WARNING

WARNING

To reduce the risk of injury, wear safety goggles or glasses with side shields. Unplug the tool before changing accessories or making adjustments.

Using Forward/Reverse Switch

Fig. 2

Reverse

Forward

1.For forward (clockwise) rotation, slide the forward/reverse switch to the left.

2.For reverse (counterclockwise) rotation, slide the forward/reverse switch to the right.

NOTE: To prevent damage to the motor, allow the tool to come to a complete stop before reversing.

![]() WARNING

WARNING

To reduce the risk of explosion, electric shock and property dam- age, always check the work area for hidden electrical wires or pipes when drilling.

Starting, Stopping and Controlling Speed

1.To start the tool, pull the paddle switch.

2.To stop the tool, release the paddle switch.

3.To vary the driving speed, increase or decrease pressure on the paddle switch. The further the paddle switch is pulled, the greater the speed.

WARNING

To reduce the risk of explosion, electric shock and property dam- age, always check the work area for hidden electrical wires or pipes when drilling.

Drilling

1.Before drilling, be sure the workpiece is clamped securely. Use backing material to prevent damage to the workpiece during breakthrough.

2.When starting a hole, place the drill bit on the work surface and apply firm pressure. Begin drilling at a slow speed, gradually increasing the speed as you drill.

3.Use enough pressure on the tool to keep the bit drilling or driving constantly, but do not push hard enough to stall the bit.

4.Reduce pressure and ease the bit through the last part of the hole. While the tool is still running, pull the bit out of the hole to prevent jamming.

Stalling

If the tool seems as if it is about to stall, main- tain a firm grip and reduce pressure slightly to allow the bit to regain speed. If the tool does stall, release the paddle switch immediately. Reverse the motor, remove the bit from the work and start again. Do not press the paddle switch on and off in an attempt to start a stalled drill. This can damage the drill.

APPLICATIONS

Selecting Bits

When selecting a bit, use the right type for your job. For best performance, always use sharp bits.

Drilling in Wood, Composition Materials and Plastic

When drilling in wood, composition materials and plastic, start the drill slowly, gradually increasing speed as you drill. When using twist drill bits, pull the bit out of the hole frequently to clear chips from the bit flutes. Use low speeds for plastics with a low melt- ing point.

Drilling in Masonry

When drilling in masonry, use high speed

Drilling in Metal

When drilling in metal, use high speed steel twist drills or hole saws. Use slow speeds for hard metals and high speeds for softer metals. Lubricate drill bits with cutting oil when drilling in iron or steel. Use a coolant when drilling in nonferrous metals such as copper, brass or aluminum. Back the ma- terial to prevent binding and distortion on breakthrough.

Driving Screws

When driving screws, use the proper screw- driver bit for your job. After drilling pilot and shank holes, start the screw slowly and increase the speed as driving progresses. Set the screw by slowing to a stop. Do not run screws down at excessive speeds. To remove screws, reverse the motor.

6

7