•When battery pack is not in use, keep it away from other metal objects like paper clips, coins, keys, nails, screws, or other small metal objects that can make a connection from one terminal to another. Shorting the battery termi- nals together may cause burns or a fire.

•Under abusive conditions, liquid may be eject- ed from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

SERVICE

•Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

SPECIFIC SAFETY RULES

•Wear ear protectors when impact drilling. Exposure to noise can cause hearing loss.

•Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal injury.

•Hold power tool by insulated gripping sur- faces, when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

•Keep hands away from all cutting edges and moving parts.

•Maintain labels and nameplates. These carry important information. If unreadable or missing, contact a MILWAUKEE service facility for a free replacement.

•WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•lead from

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

SYMBOLOGY

Volts

Direct Current

No Load Revolutions per

Minute (RPM)

Underwriters Laboratories, Inc.

United States and Canada

SPECIFICATIONS

|

| No |

| Capacities |

| |

| Volts | Drilling | Drilling | Driving | ||

Cat. No. | Load | in Wood | in Wood | |||

DC | RPM | (twist bit) | (spade bit) | Screws | ||

12 | 3/8" | 1" | 1/4" | |||

diameter | ||||||

|

|

|

|

|

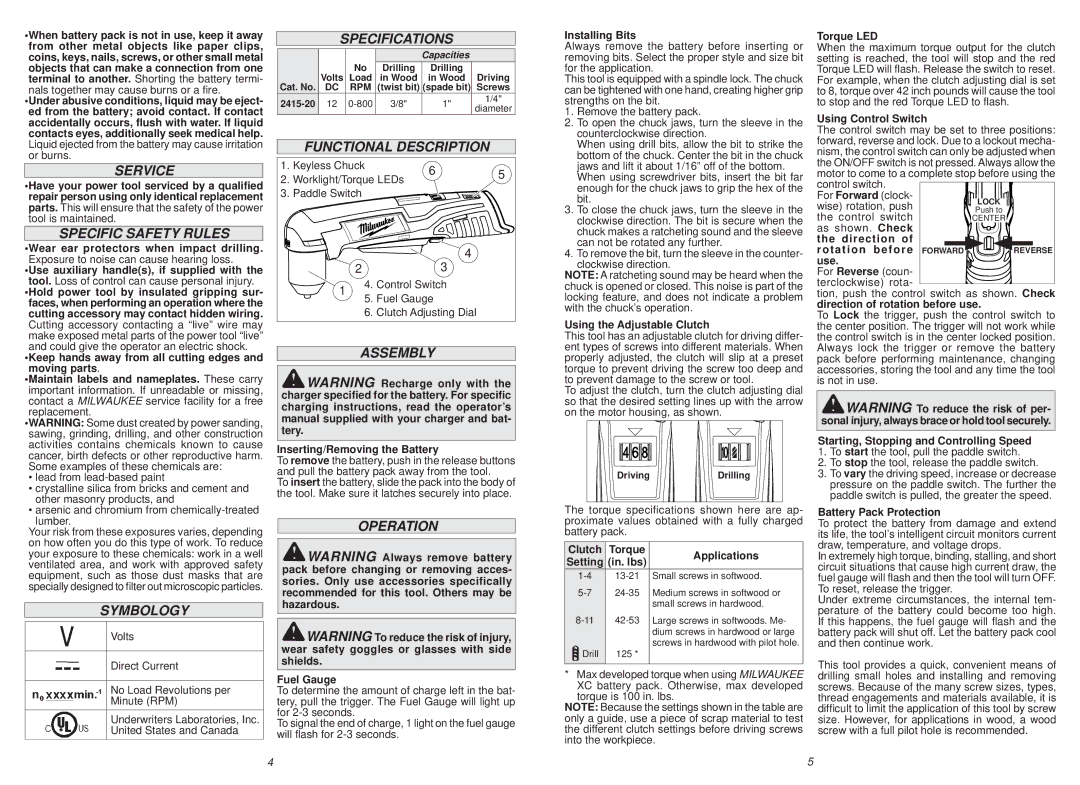

FUNCTIONAL DESCRIPTION

1. | Keyless Chuck |

| 6 | 5 | ||

2. | Worklight/Torque LEDs | |||||

|

| |||||

3. | Paddle Switch |

|

|

|

| |

|

|

|

|

| 4 | |

| 2 |

|

|

| 3 | |

| 1 | 4. | Control Switch | |||

| 5. | Fuel Gauge |

| |||

|

|

| ||||

|

| 6. | Clutch Adjusting Dial | |||

ASSEMBLY

![]() WARNING Recharge only with the charger specified for the battery. For specific charging instructions, read the operator’s manual supplied with your charger and bat- tery.

WARNING Recharge only with the charger specified for the battery. For specific charging instructions, read the operator’s manual supplied with your charger and bat- tery.

Inserting/Removing the Battery

To remove the battery, push in the release buttons and pull the battery pack away from the tool.

To insert the battery, slide the pack into the body of the tool. Make sure it latches securely into place.

OPERATION

![]() WARNING Always remove battery pack before changing or removing acces- sories. Only use accessories specifically recommended for this tool. Others may be hazardous.

WARNING Always remove battery pack before changing or removing acces- sories. Only use accessories specifically recommended for this tool. Others may be hazardous.

![]() WARNING To reduce the risk of injury, wear safety goggles or glasses with side shields.

WARNING To reduce the risk of injury, wear safety goggles or glasses with side shields.

Fuel Gauge

To determine the amount of charge left in the bat- tery, pull the trigger. The Fuel Gauge will light up for

To signal the end of charge, 1 light on the fuel gauge will flash for

Installing Bits

Always remove the battery before inserting or removing bits. Select the proper style and size bit for the application.

This tool is equipped with a spindle lock. The chuck can be tightened with one hand, creating higher grip strengths on the bit.

1.Remove the battery pack.

2.To open the chuck jaws, turn the sleeve in the counterclockwise direction.

When using drill bits, allow the bit to strike the bottom of the chuck. Center the bit in the chuck jaws and lift it about 1/16” off of the bottom.

When using screwdriver bits, insert the bit far enough for the chuck jaws to grip the hex of the bit.

3.To close the chuck jaws, turn the sleeve in the clockwise direction. The bit is secure when the chuck makes a ratcheting sound and the sleeve can not be rotated any further.

4.To remove the bit, turn the sleeve in the counter- clockwise direction.

NOTE: A ratcheting sound may be heard when the chuck is opened or closed. This noise is part of the locking feature, and does not indicate a problem with the chuck’s operation.

Using the Adjustable Clutch

This tool has an adjustable clutch for driving differ- ent types of screws into different materials. When properly adjusted, the clutch will slip at a preset torque to prevent driving the screw too deep and to prevent damage to the screw or tool.

To adjust the clutch, turn the clutch adjusting dial so that the desired setting lines up with the arrow on the motor housing, as shown.

Driving | Drilling |

The torque specifications shown here are ap- proximate values obtained with a fully charged battery pack.

Clutch | Torque | Applications | |

Setting | (in. lbs) | ||

| |||

Small screws in softwood. | |||

Medium screws in softwood or | |||

|

| small screws in hardwood. | |

Large screws in softwoods. Me- | |||

|

| dium screws in hardwood or large | |

Drill | 125 * | screws in hardwood with pilot hole. | |

| |||

|

|

|

*Max developed torque when using MILWAUKEE XC battery pack. Otherwise, max developed

torque is 100 in. lbs.

NOTE: Because the settings shown in the table are only a guide, use a piece of scrap material to test the different clutch settings before driving screws into the workpiece.

Torque LED

When the maximum torque output for the clutch setting is reached, the tool will stop and the red Torque LED will flash. Release the switch to reset. For example, when the clutch adjusting dial is set to 8, torque over 42 inch pounds will cause the tool to stop and the red Torque LED to flash.

Using Control Switch

The control switch may be set to three positions: forward, reverse and lock. Due to a lockout mecha-

nism, the control switch can only be adjusted when | ||

the ON/OFF switch is not pressed. Always allow the | ||

motor to come to a complete stop before using the | ||

control switch. |

| |

For Forward (clock- | LOCK | |

wise) rotation, push | ||

Push to | ||

the control switch | CENTER | |

as shown. Check |

| |

the direction of |

| |

rotation before FORWARD | REVERSE | |

use. |

| |

For Reverse (coun- |

| |

terclockwise) rota- |

| |

tion, push the control switch as shown. Check | ||

direction of rotation before use. | ||

To Lock the trigger, push the control switch to the center position. The trigger will not work while the control switch is in the center locked position. Always lock the trigger or remove the battery pack before performing maintenance, changing accessories, storing the tool and any time the tool is not in use.

WARNING To reduce the risk of per- sonal injury, always brace or hold tool securely.

Starting, Stopping and Controlling Speed

1.To start the tool, pull the paddle switch.

2.To stop the tool, release the paddle switch.

3.To vary the driving speed, increase or decrease pressure on the paddle switch. The further the paddle switch is pulled, the greater the speed.

Battery Pack Protection

To protect the battery from damage and extend its life, the tool’s intelligent circuit monitors current draw, temperature, and voltage drops.

In extremely high torque, binding, stalling, and short circuit situations that cause high current draw, the fuel gauge will flash and then the tool will turn OFF. To reset, release the trigger.

Under extreme circumstances, the internal tem- perature of the battery could become too high. If this happens, the fuel gauge will flash and the battery pack will shut off. Let the battery pack cool and then continue work.

This tool provides a quick, convenient means of drilling small holes and installing and removing screws. Because of the many screw sizes, types, thread engagements and materials available, it is difficult to limit the application of this tool by screw size. However, for applications in wood, a wood screw with a full pilot hole is recommended.

4 | 5 |