•Use power tools only with specifically desig- nated battery packs. Use of any other battery

•Store tool with expander head installed to protect expander cone from damage.

OPERATION

packs may create a risk of injury and fire.

•When battery pack is not in use, keep it away from other metal objects like paper clips, coins, keys, nails, screws, or other small metal objects that can make a connection from one terminal to another. Shorting the battery termi- nals together may cause burns or a fire.

•Under abusive conditions, liquid may be eject- ed from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

SERVICE

•Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

SPECIFIC SAFETY RULES

•Use tool only to expand

•Keep fingers away from expander head during use. When expander head contracts, pinching can occur.

•Maintain labels and nameplates. These carry important information. If unreadable or missing, contact a MILWAUKEE service facility for a free replacement.

•WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•lead from

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are spe- cially designed to filter out microscopic particles.

WARNING Always remove battery pack before changing or removing acces- sories. Only use accessories specifically recommended for this tool. Others may be hazardous.

WARNING To reduce the risk of injury, wear safety goggles or glasses with side shields.

Fuel Gauge

To determine the amount of charge left in the bat- tery, pull the trigger. The Fuel Gauge will light up for

To signal the end of charge, 1 light on the fuel gauge will flash for

Trigger Lock

To lock ![]() the trigger, push the trigger lock from the left side of the tool. The trigger will not work while the switch is in the locked position. Lock the trigger when storing the tool and when the tool is not in use.

the trigger, push the trigger lock from the left side of the tool. The trigger will not work while the switch is in the locked position. Lock the trigger when storing the tool and when the tool is not in use.

3.Insert the expander head into the PEX tubing.

4.Pull the trigger. The expander head will expand, retract, and rotate slightly in each cycle. NOTE: When Uponor ![]()

Standard expander heads are used, the head will NOT rotate automatically. Each time the segments contract, gently push

the tubing up onto the expander head and rotate 1/8 turn in either direction.

CAUTION When using Uponor Standard expansion heads, properly rotate the tubing after each expansion to create even, smooth expansion marks. Not rotating the tubing may cause deep grooves and faulty connections, which could result in leaking and property damage.

Expansion |

markings |

inside tubing |

SPECIFICATIONS

Cat. No. | Volts DC | Max | Expander Heads | Lubricant |

12 | 3/8" - 1" | 3/8" - 1" MILWAUKEE M12™ | Expander Cone | |

ProPEX™ or Uponor Standard | Grease | |||

|

|

|

| Cat.No. |

SYMBOLOGYASSEMBLY

To unlock ![]() the trigger, push the trigger lock from the right side of the tool.

the trigger, push the trigger lock from the right side of the tool.

CAUTION Use only MILWAUKEE M12™ ProPEX™ expander heads or Uponor Stan- dard expander heads. The use of incorrectly sized expansion heads may result in faulty connections, which could result in property damage.

Making PEX Tubing Connections

| Incorrect |

| Correct |

Ring Size | Number of Expansions with Ring* |

3/8" PEX | |

1/2" PEX | |

5/8" PEX | |

3/4" PEX |

Direct Current

Underwriters Laboratories, Inc.

United States and Canada

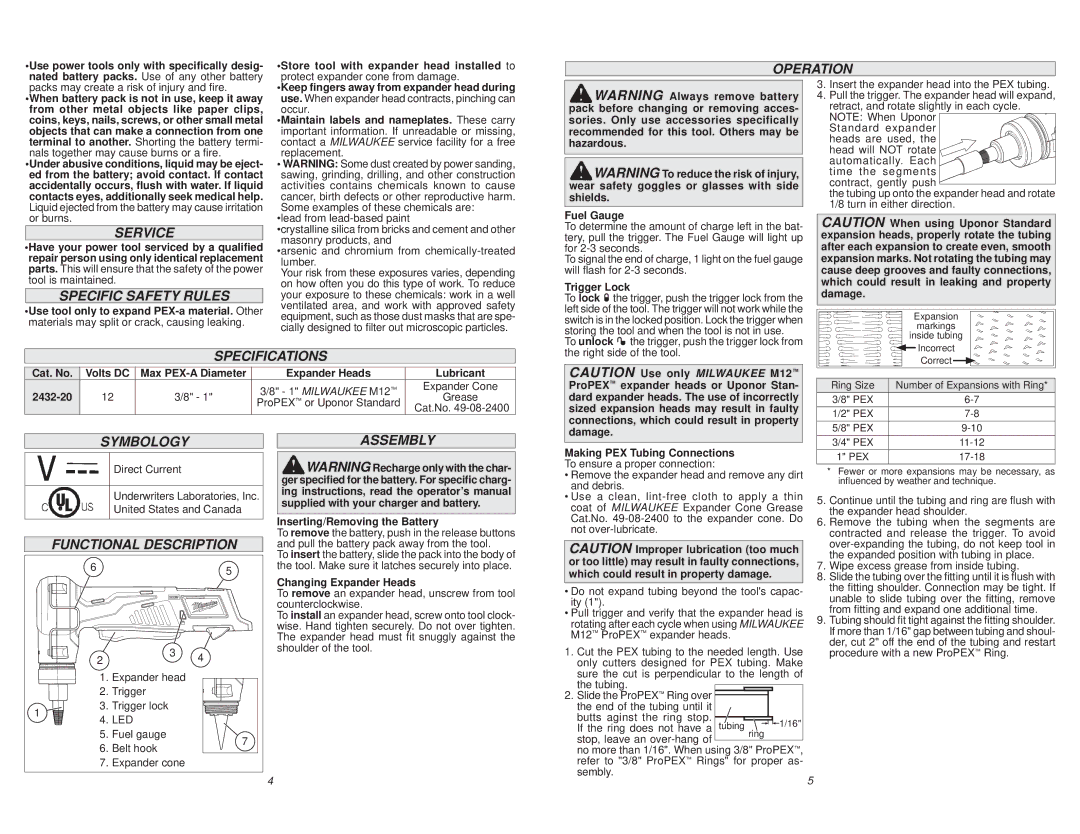

FUNCTIONAL DESCRIPTION

| 6 |

| 5 |

|

|

| |

| 2 | 3 | 4 |

|

| ||

| 1. | Expander head |

|

| 2. | Trigger |

|

1 | 3. | Trigger lock |

|

4. | LED |

| |

|

| ||

| 5. | Fuel gauge | 7 |

| 6. | Belt hook | |

|

| ||

| 7. | Expander cone |

|

WARNING Recharge only with the char- ger specified for the battery. For specific charg- ing instructions, read the operator’s manual supplied with your charger and battery.

Inserting/Removing the Battery

To remove the battery, push in the release buttons and pull the battery pack away from the tool.

To insert the battery, slide the pack into the body of the tool. Make sure it latches securely into place.

Changing Expander Heads

To remove an expander head, unscrew from tool counterclockwise.

To install an expander head, screw onto tool clock- wise. Hand tighten securely. Do not over tighten. The expander head must fit snuggly against the shoulder of the tool.

4

To ensure a proper connection:

•Remove the expander head and remove any dirt and debris.

•Use a clean,

CAUTION Improper lubrication (too much or too little) may result in faulty connections, which could result in property damage.

•Do not expand tubing beyond the tool's capac- ity (1").

•Pull trigger and verify that the expander head is rotating after each cycle when using MILWAUKEE M12™ ProPEX™ expander heads.

1.Cut the PEX tubing to the needed length. Use only cutters designed for PEX tubing. Make sure the cut is perpendicular to the length of

the tubing. |

|

|

|

|

|

|

|

|

|

2. Slide the ProPEX™ Ring over |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

the end of the tubing until it |

|

|

|

|

|

|

|

|

|

butts aginst the ring stop. |

|

|

|

|

|

|

|

| 1/16" |

If the ring does not have a | tubing |

|

|

|

|

|

| ||

stop, leave an |

|

| ring | ||||||

|

|

|

|

|

|

|

|

| |

no more than 1/16". When using 3/8" ProPEX™, | |||||||||

refer to "3/8" ProPEX™ Rings" for proper as- | |||||||||

sembly. |

|

|

|

|

|

|

|

|

|

1" PEX |

*Fewer or more expansions may be necessary, as influenced by weather and technique.

5.Continue until the tubing and ring are flush with the expander head shoulder.

6.Remove the tubing when the segments are contracted and release the trigger. To avoid

7.Wipe excess grease from inside tubing.

8.Slide the tubing over the fitting until it is flush with the fitting shoulder. Connection may be tight. If unable to slide tubing over the fitting, remove from fitting and expand one additional time.

9.Tubing should fit tight against the fitting shoulder. If more than 1/16" gap between tubing and shoul- der, cut 2" off the end of the tubing and restart procedure with a new ProPEX™ Ring.

5