TOOL ASSEMBLY

![]() WARNING!

WARNING!

To reduce the risk of injury, always unplug tool before attaching or removing accessories or making adjustments. Use only specifically recommended accessories. Others may be hazardous.

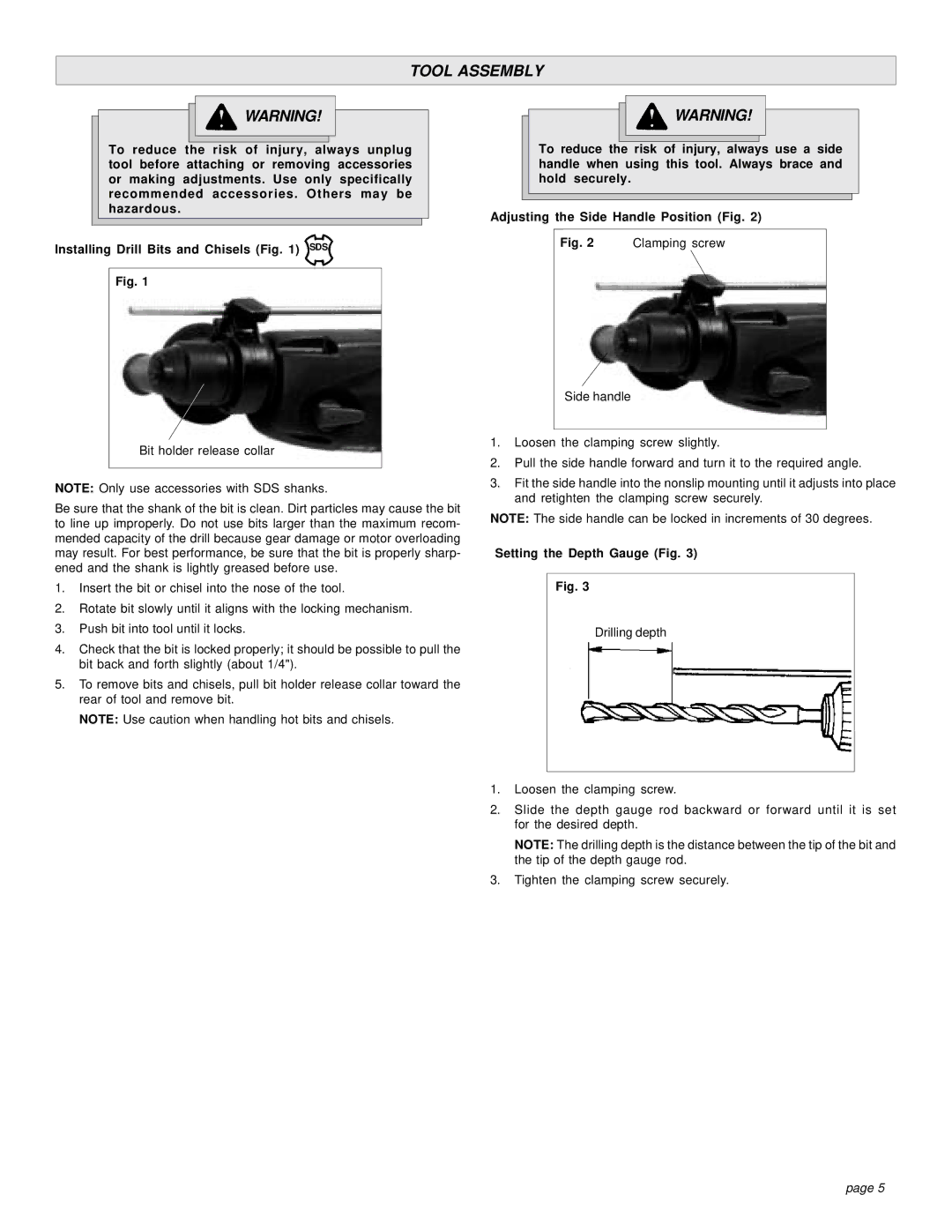

Installing Drill Bits and Chisels (Fig. 1) SDS

Fig. 1

Bit holder release collar

![]() WARNING!

WARNING!

To reduce the risk of injury, always use a side handle when using this tool. Always brace and hold securely.

Adjusting the Side Handle Position (Fig. 2)

Fig. 2 Clamping screw

Side handle

1.Loosen the clamping screw slightly.

2.Pull the side handle forward and turn it to the required angle.

NOTE: Only use accessories with SDS shanks.

Be sure that the shank of the bit is clean. Dirt particles may cause the bit to line up improperly. Do not use bits larger than the maximum recom- mended capacity of the drill because gear damage or motor overloading may result. For best performance, be sure that the bit is properly sharp- ened and the shank is lightly greased before use.

1.Insert the bit or chisel into the nose of the tool.

2.Rotate bit slowly until it aligns with the locking mechanism.

3.Push bit into tool until it locks.

4.Check that the bit is locked properly; it should be possible to pull the bit back and forth slightly (about 1/4").

5.To remove bits and chisels, pull bit holder release collar toward the rear of tool and remove bit.

NOTE: Use caution when handling hot bits and chisels.

3.Fit the side handle into the nonslip mounting until it adjusts into place and retighten the clamping screw securely.

NOTE: The side handle can be locked in increments of 30 degrees.

Setting the Depth Gauge (Fig. 3)

Fig. 3

Drilling depth

1.Loosen the clamping screw.

2.Slide the depth gauge rod backward or forward until it is set for the desired depth.

NOTE: The drilling depth is the distance between the tip of the bit and the tip of the depth gauge rod.

3.Tighten the clamping screw securely.

page 5