9.Make sure the plate on the saw motor is flush against the leveling screw to ensure the saw is square (Fig. 5). This screw is factory set and does not require adjustments.

10.Tighten the two NUTS ON STUDS FIRST and tighten the NUT ON BOLT LAST.

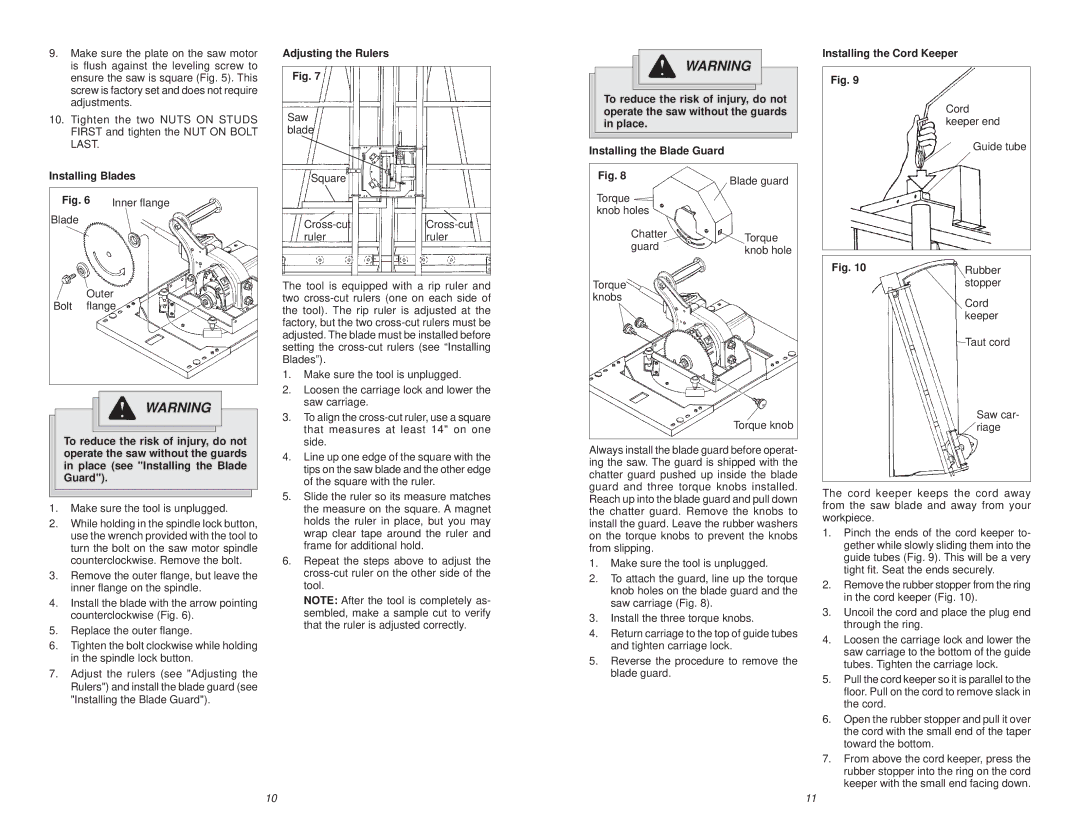

Installing Blades

Fig. 6 | Inner flange |

Blade |

|

![]() Outer

Outer

Bolt flange

WARNING

To reduce the risk of injury, do not operate the saw without the guards in place (see "Installing the Blade Guard").

1.Make sure the tool is unplugged.

2.While holding in the spindle lock button, use the wrench provided with the tool to turn the bolt on the saw motor spindle counterclockwise. Remove the bolt.

3.Remove the outer flange, but leave the inner flange on the spindle.

4.Install the blade with the arrow pointing counterclockwise (Fig. 6).

5.Replace the outer flange.

6.Tighten the bolt clockwise while holding in the spindle lock button.

7.Adjust the rulers (see "Adjusting the Rulers") and install the blade guard (see "Installing the Blade Guard").

Adjusting the Rulers

Fig. 7

Saw blade

Square

ruler | ruler |

The tool is equipped with a rip ruler and two

1.Make sure the tool is unplugged.

2.Loosen the carriage lock and lower the saw carriage.

3.To align the

4.Line up one edge of the square with the tips on the saw blade and the other edge of the square with the ruler.

5.Slide the ruler so its measure matches the measure on the square. A magnet holds the ruler in place, but you may wrap clear tape around the ruler and frame for additional hold.

6.Repeat the steps above to adjust the

NOTE: After the tool is completely as- sembled, make a sample cut to verify that the ruler is adjusted correctly.

WARNING

To reduce the risk of injury, do not operate the saw without the guards in place.

Installing the Blade Guard

Fig. 8 | Blade guard | |

| ||

Torque |

| |

knob holes |

| |

Chatter | Torque | |

guard | ||

knob hole | ||

| ||

Torque |

| |

knobs |

|

Torque knob

Always install the blade guard before operat- ing the saw. The guard is shipped with the chatter guard pushed up inside the blade guard and three torque knobs installed. Reach up into the blade guard and pull down the chatter guard. Remove the knobs to install the guard. Leave the rubber washers on the torque knobs to prevent the knobs from slipping.

1.Make sure the tool is unplugged.

2.To attach the guard, line up the torque knob holes on the blade guard and the saw carriage (Fig. 8).

3.Install the three torque knobs.

4.Return carriage to the top of guide tubes and tighten carriage lock.

5.Reverse the procedure to remove the blade guard.

Installing the Cord Keeper

Fig. 9

Cord keeper end

Guide tube

Fig. 10 | Rubber |

| stopper |

Cord keeper

Taut cord

Saw car- riage

The cord keeper keeps the cord away from the saw blade and away from your workpiece.

1.Pinch the ends of the cord keeper to- gether while slowly sliding them into the guide tubes (Fig. 9). This will be a very tight fit. Seat the ends securely.

2.Remove the rubber stopper from the ring in the cord keeper (Fig. 10).

3.Uncoil the cord and place the plug end through the ring.

4.Loosen the carriage lock and lower the saw carriage to the bottom of the guide tubes. Tighten the carriage lock.

5.Pull the cord keeper so it is parallel to the floor. Pull on the cord to remove slack in the cord.

6.Open the rubber stopper and pull it over the cord with the small end of the taper toward the bottom.

7.From above the cord keeper, press the rubber stopper into the ring on the cord keeper with the small end facing down.

10 | 11 |