6527 specifications

Milwaukee 6527 is a robust and powerful tool designed to elevate the efficiency and versatility of both professional contractors and DIY enthusiasts. As part of Milwaukee's esteemed lineup of innovative products, the 6527 model stands out for its exceptional performance, durability, and advanced technological features that cater to various construction and renovation tasks.One of the main features of the Milwaukee 6527 is its high-performance motor, delivering outstanding power and torque. This tool is engineered for heavy-duty applications, making it suitable for cutting, grinding, and polishing tasks across numerous materials including metal, wood, and masonry. The motor’s performance is complemented by a built-in electronic speed control system, allowing users to adjust the tool's speed to match the specific requirements of each job, resulting in enhanced precision and better finishes.

In terms of design, Milwaukee 6527 boasts an ergonomic handle which provides a comfortable grip during extended use. This thoughtful design minimizes user fatigue and enhances overall control, making it easier to handle the tool in tight or awkward positions. The lightweight build of the tool further contributes to its versatility, allowing for easy maneuverability without compromising on power.

Milwaukee has integrated advanced safety features into the 6527 model, ensuring that users can operate it with peace of mind. These include an overload protection system, which helps prevent potential damage to the tool during extensive use, and a safety lock-off switch that prevents accidental start-ups. These safety measures are essential in maintaining both the tool's longevity and the user’s well-being.

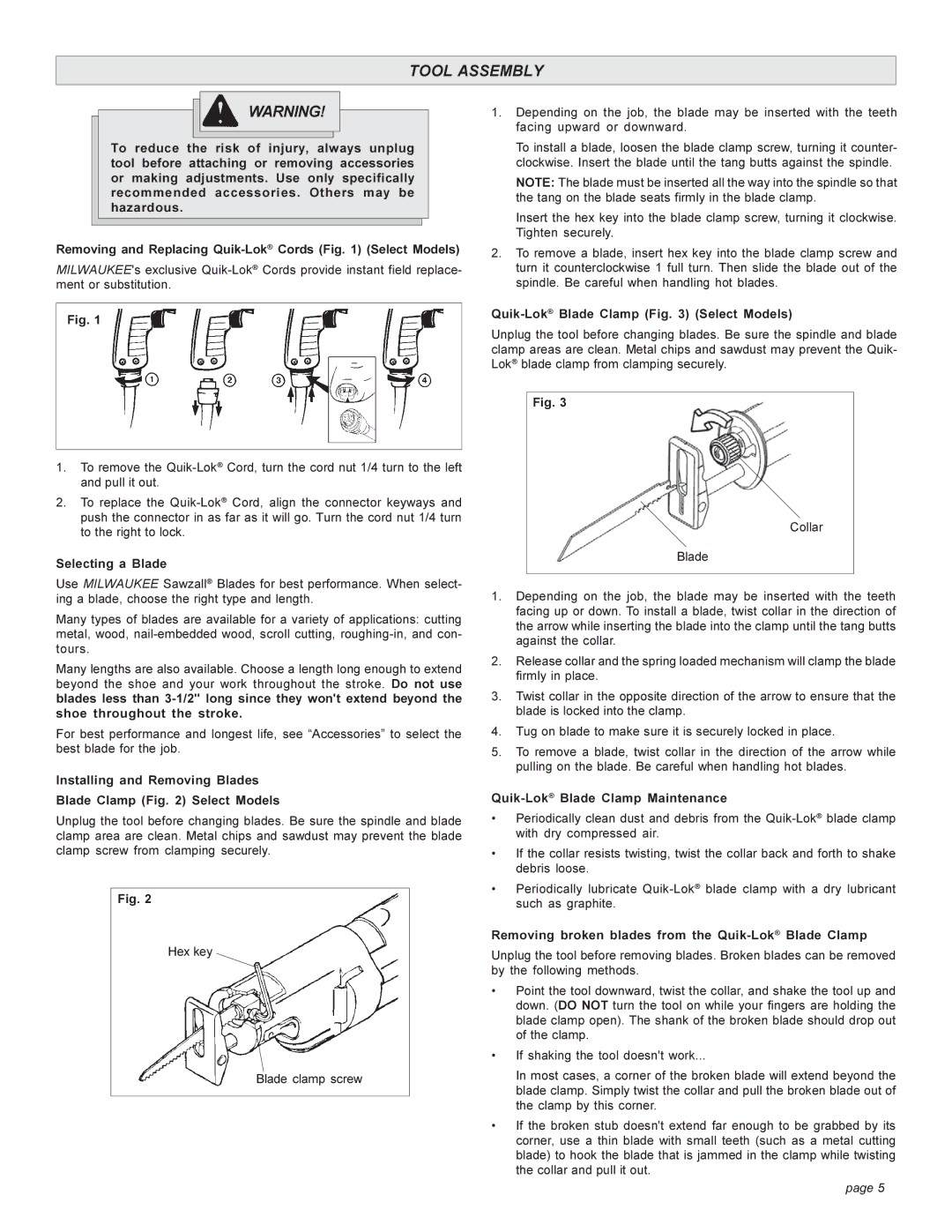

Additionally, the Milwaukee 6527 incorporates a quick-change accessory system, allowing users to swap out blades and attachments in mere seconds without the need for additional tools. This feature significantly enhances workflow efficiency and enables users to tackle multi-faceted projects with ease.

Moreover, Milwaukee is renowned for its commitment to innovation and quality, and the 6527 is no exception. Supported by Milwaukee's reliable warranty and customer support, this tool represents a significant investment for professionals seeking to enhance their toolkit. With its blend of power, convenience, and safety, Milwaukee 6527 is certainly a worthwhile addition for anyone serious about their work in construction and renovation.