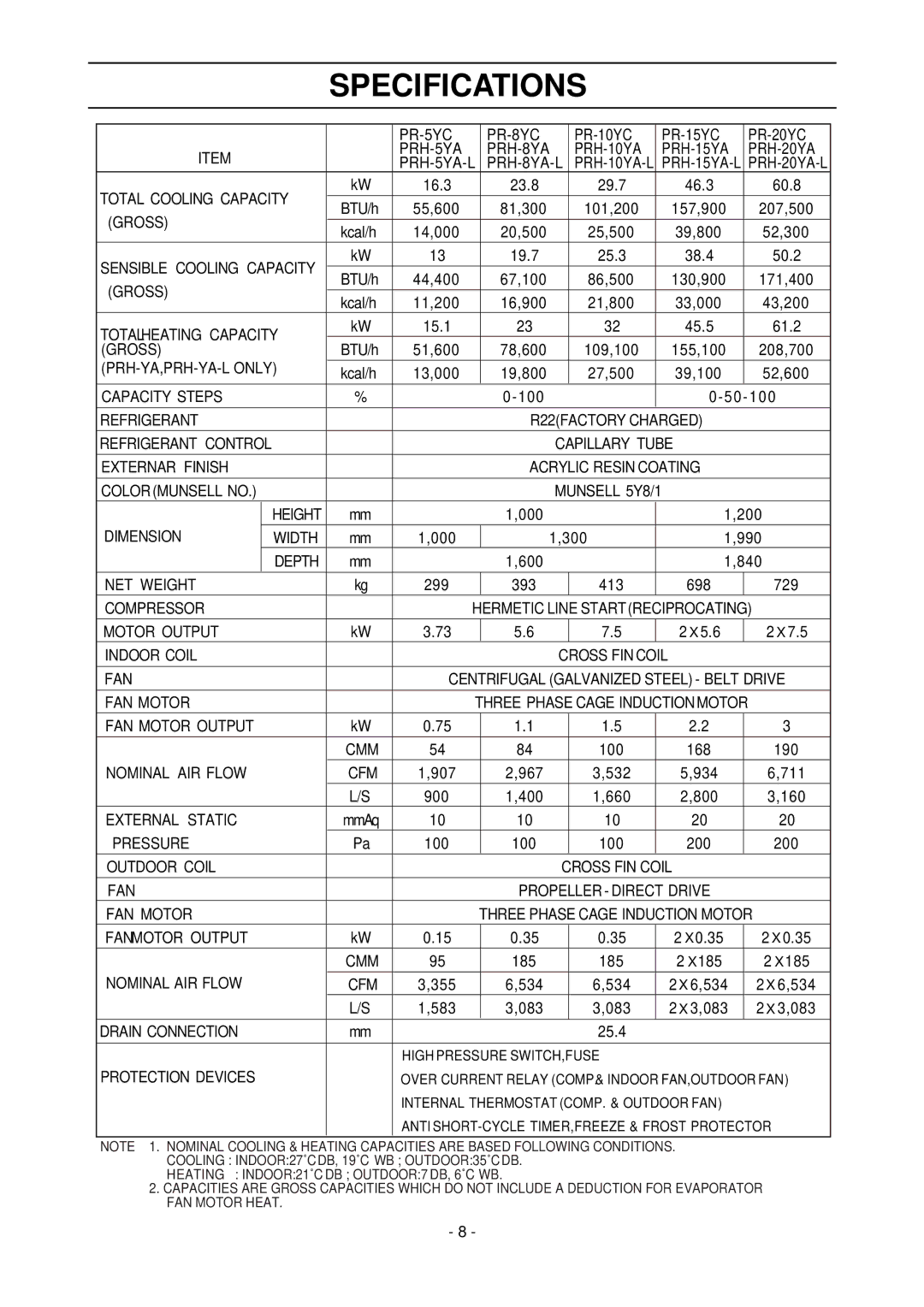

20-L, 8, PRH-5, 15, 10 specifications

Mitsubishi Electronics has long been a prominent player in the field of industrial automation, and their PRH series of smart human-machine interfaces (HMIs) is a testament to their innovative approach. The PRH-5, PRH-10, PRH-15, and the PRH-5,8 models exemplify the brand’s commitment to providing advanced technologies that enhance user interaction and facilitate the management of complex systems.One of the main features of the PRH series is its high-resolution touch screen display, which provides clear and vibrant visuals for monitoring and controlling machinery. The screens offer exceptional clarity, making it easier for operators to interpret data and respond to system alerts promptly. The multi-touch capabilities allow for intuitive navigation, enhancing the user experience significantly.

The PRH series is equipped with robust communication technologies, including support for various industrial protocols such as MODBUS, Ethernet/IP, and Profinet. This flexibility enables seamless integration with a wide range of devices and systems, allowing for centralized control and monitoring of operations. Such interoperability is vital in modern manufacturing and process industries where diverse equipment needs to work harmoniously.

Another significant characteristic of the PRH series is its advanced data logging capabilities. These HMIs are designed to collect and store critical operational data, providing insights that can be analyzed for performance optimization and predictive maintenance. This feature is essential for minimizing downtime and ensuring that manufacturing processes operate at peak efficiency.

In terms of design, the PRH-5, PRH-10, PRH-15, and PRH-5,8 models feature a sleek and compact profile, making them suitable for installation in various environments, even where space is limited. They are built to withstand harsh industrial conditions, ensuring reliability and durability over long periods of use.

User-friendly software tools accompany the PRH series, enabling easy customization and programming of the interface to suit specific operational needs. Mitsubishi Electronics focuses on ensuring that users, regardless of their technical skills, can configure and manage the HMIs effectively.

In summary, Mitsubishi Electronics' PRH-5, PRH-10, PRH-15, and PRH-5,8 models represent the forefront of HMI technology. With high-resolution displays, extensive communication support, robust data logging capabilities, and user-friendly design, these devices are perfectly equipped to meet the challenges of modern industrial automation.