AIR SYSTEM

An air pulsation chamber is located on the left side of the unit. The air is supplied to the chamber from the compressor. The chamber is eouipped with an air pressure gauge and a safety valve. The safety valve is set at the factory at approximately 60 lbs.

HI-VOLUME PUMP

An outstanding feature of the ESSICK MODEL FM9 finishing machine is that two different size pumps may be used, which tremendously increases its versatility. A more powerful engine and transmission are designed into this unit and a

The installation of this pump is very easy because all parts are interchangeable. It is only necessary to remove the rotor pin, which fastens the rotor to the connecting rod located at the bottom of the material hopper, and then thread out the stator tube with the rotor encased, and install the

Fireproofing is one application where the

To obtain maximum volume we suggest not to use more than 75 feet of

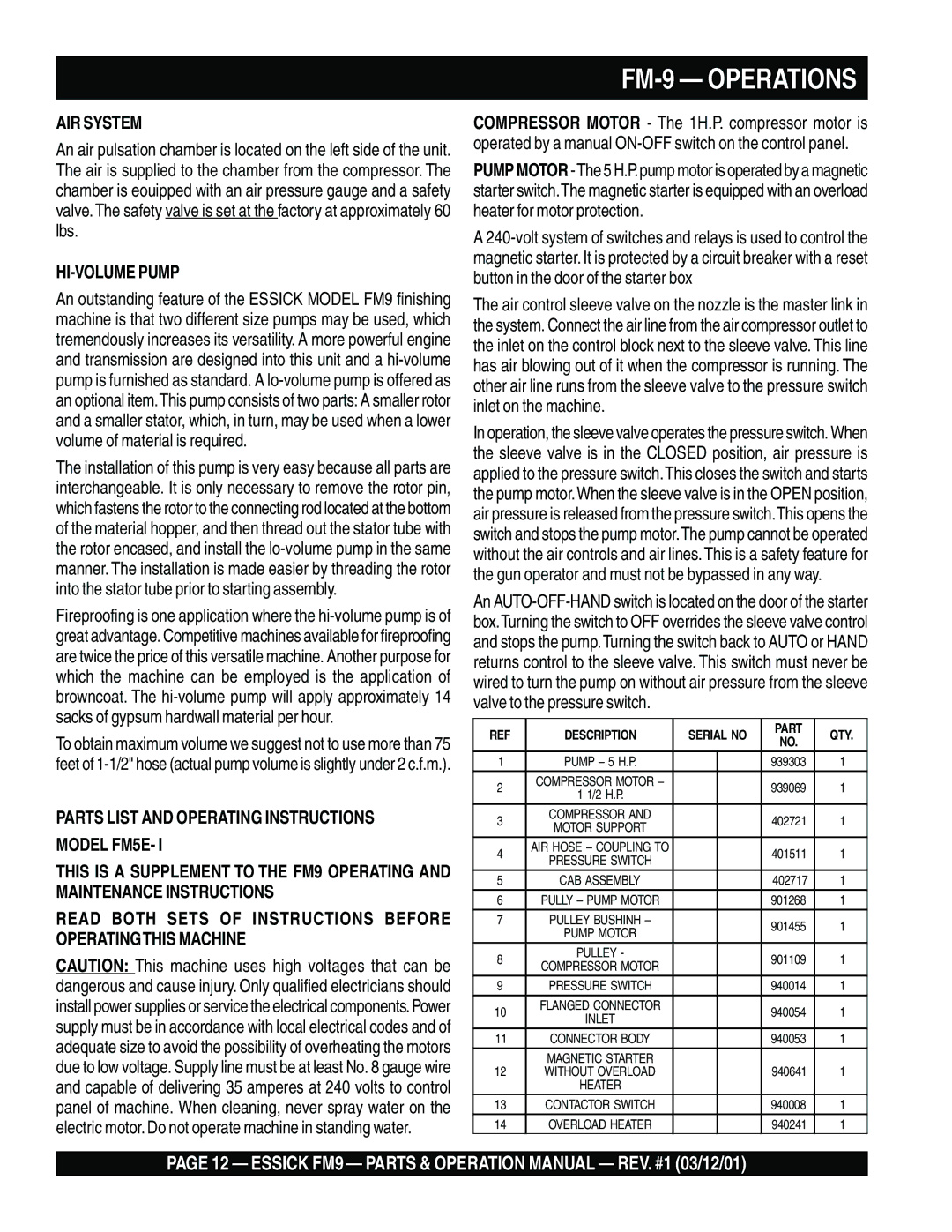

PARTS LIST AND OPERATING INSTRUCTIONS

MODEL FM5E- I

THIS IS A SUPPLEMENT TO THE FM9 OPERATING AND MAINTENANCE INSTRUCTIONS

READ BOTH SETS OF INSTRUCTIONS BEFORE OPERATINGTHIS MACHINE

CAUTION: This machine uses high voltages that can be dangerous and cause injury. Only qualified electricians should install power supplies or service the electrical components. Power supply must be in accordance with local electrical codes and of adequate size to avoid the possibility of overheating the motors due to low voltage. Supply line must be at least No. 8 gauge wire and capable of delivering 35 amperes at 240 volts to control panel of machine. When cleaning, never spray water on the electric motor. Do not operate machine in standing water.

FM-9 — OPERATIONS

COMPRESSOR MOTOR - The 1H.P. compressor motor is operated by a manual

PUMP MOTOR

A

The air control sleeve valve on the nozzle is the master link in the system. Connect the air line from the air compressor outlet to the inlet on the control block next to the sleeve valve. This line has air blowing out of it when the compressor is running. The other air line runs from the sleeve valve to the pressure switch inlet on the machine.

In operation, the sleeve valve operates the pressure switch. When the sleeve valve is in the CLOSED position, air pressure is applied to the pressure switch.This closes the switch and starts the pump motor.When the sleeve valve is in the OPEN position, air pressure is released from the pressure switch.This opens the switch and stops the pump motor.The pump cannot be operated without the air controls and air lines. This is a safety feature for the gun operator and must not be bypassed in any way.

An

REF | DESCRIPTION | SERIAL NO | PART | QTY. | ||

NO. | ||||||

|

|

|

|

| ||

1 | PUMP – 5 H.P. |

|

| 939303 | 1 | |

2 | COMPRESSOR MOTOR – |

|

| 939069 | 1 | |

1 1/2 H.P. |

|

| ||||

|

|

|

|

| ||

3 | COMPRESSOR AND |

|

| 402721 | 1 | |

MOTOR SUPPORT |

|

| ||||

|

|

|

|

| ||

4 | AIR HOSE – COUPLING TO |

|

| 401511 | 1 | |

PRESSURE SWITCH |

|

| ||||

|

|

|

|

| ||

5 | CAB ASSEMBLY |

|

| 402717 | 1 | |

6 | PULLY – PUMP MOTOR |

|

| 901268 | 1 | |

7 | PULLEY BUSHINH – |

|

| 901455 | 1 | |

| PUMP MOTOR |

|

| |||

|

|

|

|

| ||

8 | PULLEY - |

|

| 901109 | 1 | |

COMPRESSOR MOTOR |

|

| ||||

|

|

|

|

| ||

9 | PRESSURE SWITCH |

|

| 940014 | 1 | |

10 | FLANGED CONNECTOR |

|

| 940054 | 1 | |

INLET |

|

| ||||

|

|

|

|

| ||

11 | CONNECTOR BODY |

|

| 940053 | 1 | |

| MAGNETIC STARTER |

|

|

|

| |

12 | WITHOUT OVERLOAD |

|

| 940641 | 1 | |

| HEATER |

|

|

|

| |

13 | CONTACTOR SWITCH |

|

| 940008 | 1 | |

14 | OVERLOAD HEATER |

|

| 940241 | 1 | |

PAGE 12 — ESSICK FM9 — PARTS & OPERATION MANUAL — REV. #1 (03/12/01)