ASM170 Auto Start Module

Revised

Catalog Section 40 & 75

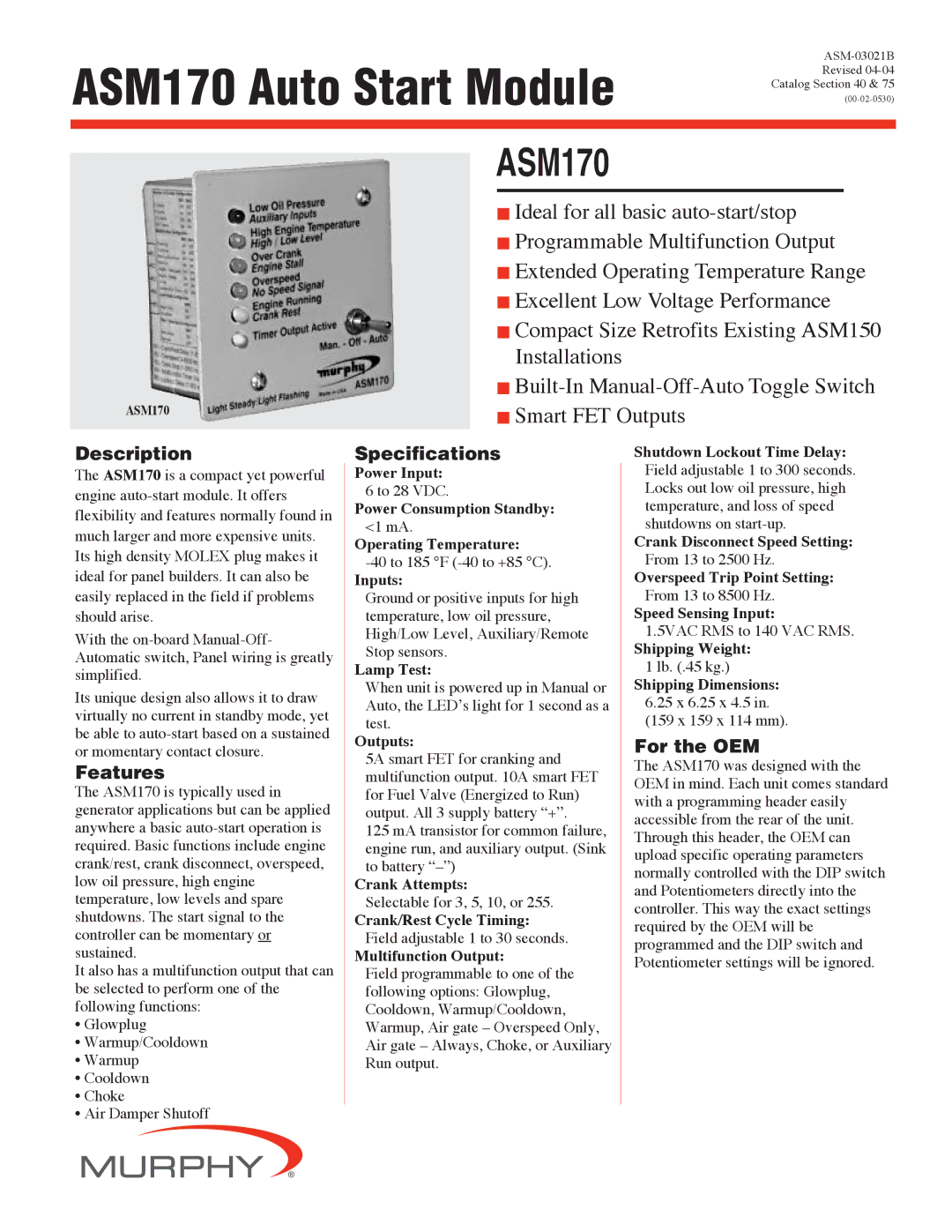

ASM170

ASM170

■Ideal for all basic

■Programmable Multifunction Output

■Extended Operating Temperature Range

■Excellent Low Voltage Performance

■Compact Size Retrofits Existing ASM150 Installations

■

■Smart FET Outputs

Description

The ASM170 is a compact yet powerful engine

With the

Its unique design also allows it to draw virtually no current in standby mode, yet be able to

Features

The ASM170 is typically used in generator applications but can be applied anywhere a basic

It also has a multifunction output that can be selected to perform one of the following functions:

•Glowplug

•Warmup/Cooldown

•Warmup

•Cooldown

•Choke

•Air Damper Shutoff

Specifications

Power Input:

6 to 28 VDC.

Power Consumption Standby:

<1 mA.

Operating Temperature:

Inputs:

Ground or positive inputs for high temperature, low oil pressure, High/Low Level, Auxiliary/Remote Stop sensors.

Lamp Test:

When unit is powered up in Manual or Auto, the LED’s light for 1 second as a test.

Outputs:

5A smart FET for cranking and multifunction output. 10A smart FET for Fuel Valve (Energized to Run) output. All 3 supply battery “+”.

125 mA transistor for common failure, engine run, and auxiliary output. (Sink to battery

Crank Attempts:

Selectable for 3, 5, 10, or 255.

Crank/Rest Cycle Timing: Field adjustable 1 to 30 seconds.

Multifunction Output:

Field programmable to one of the following options: Glowplug, Cooldown, Warmup/Cooldown, Warmup, Air gate – Overspeed Only, Air gate – Always, Choke, or Auxiliary Run output.

Shutdown Lockout Time Delay:

Field adjustable 1 to 300 seconds. Locks out low oil pressure, high temperature, and loss of speed shutdowns on

Crank Disconnect Speed Setting:

From 13 to 2500 Hz.

Overspeed Trip Point Setting:

From 13 to 8500 Hz.

Speed Sensing Input:

1.5VAC RMS to 140 VAC RMS.

Shipping Weight:

1 lb. (.45 kg.)

Shipping Dimensions:

6.25x 6.25 x 4.5 in.

(159 x 159 x 114 mm).

For the OEM

The ASM170 was designed with the OEM in mind. Each unit comes standard with a programming header easily accessible from the rear of the unit. Through this header, the OEM can upload specific operating parameters normally controlled with the DIP switch and Potentiometers directly into the controller. This way the exact settings required by the OEM will be programmed and the DIP switch and Potentiometer settings will be ignored.