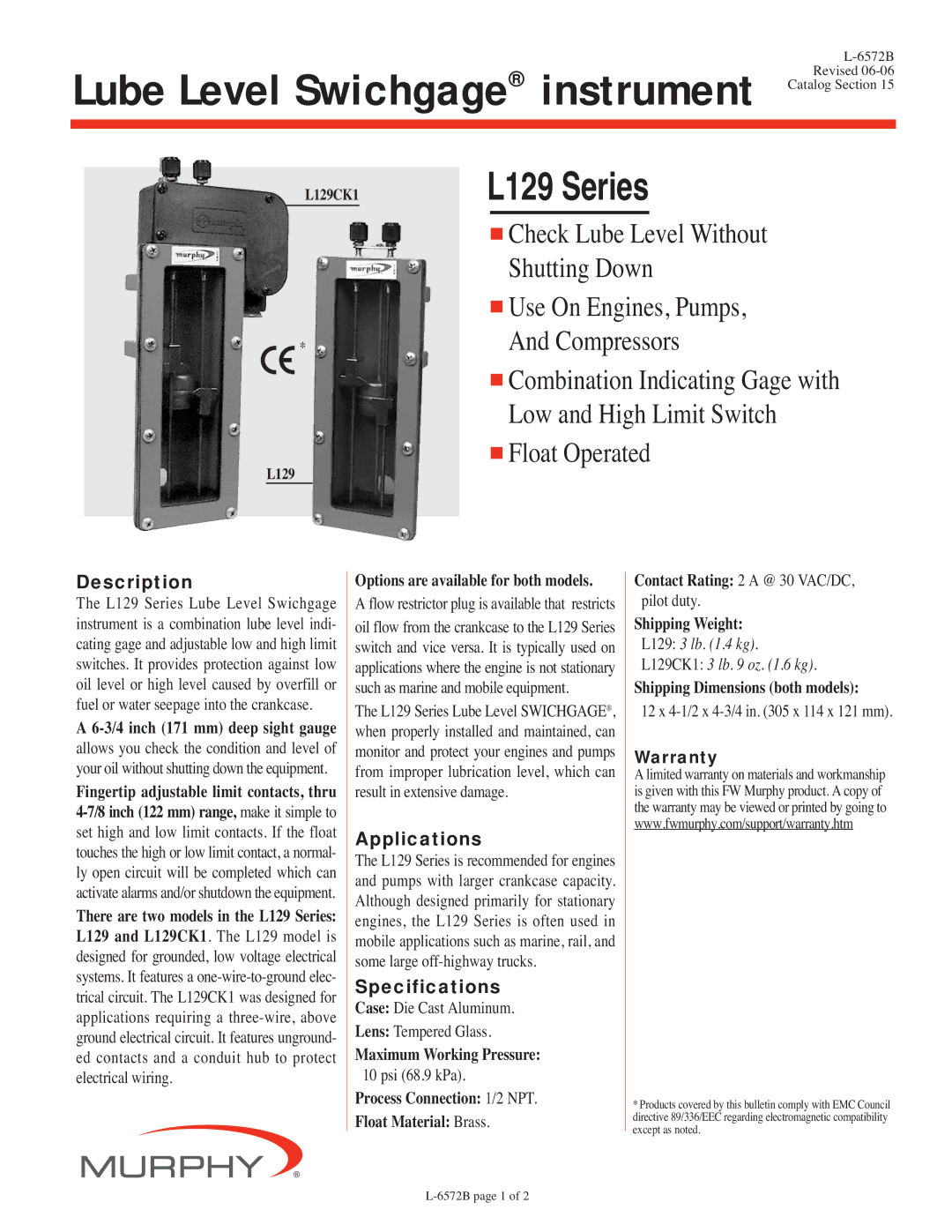

L129 Series specifications

The Murphy L129 Series represents a significant advancement in the realm of engine monitoring and control systems, tailored specifically for various industrial and commercial applications. Designed for robust performance and reliability, the L129 series excels in providing vital information that enhances engine operation, ultimately extending the life of machinery and enhancing operational efficiency.One of the standout features of the Murphy L129 Series is its ability to monitor critical engine parameters, such as oil pressure, coolant temperature, and fuel level. This comprehensive monitoring ensures that operators are promptly alerted to any potential issues, allowing for timely intervention and maintenance. The user-friendly interface offers an intuitive display, making it easy for operators to visualize real-time data and historical trends.

A notable technology embedded within the Murphy L129 Series is its integration of advanced microprocessor technology. This ensures precise measurement and processing of engine data, contributing to the accuracy of diagnostics and performance metrics. Furthermore, the system is equipped with programmable alarm settings, which can be tailored to individual engine specifications, providing customized alerts that help in managing engine health proactively.

The L129 series is also designed with environmental resilience in mind. Its rugged construction allows it to operate effectively in harsh conditions, which include extreme temperatures, moisture, and vibration. This durability makes it suitable for a wide range of applications, including construction sites, agricultural machinery, and marine engines, where reliability is paramount.

In terms of connectivity, the Murphy L129 Series supports standard communication protocols, enabling seamless integration with various control systems and data logging devices. This interoperability allows for streamlined data management and facilitates advanced analytics, providing deeper insights into engine performance.

Moreover, the series is designed with user convenience in mind. Simple installation procedures and customizable configurations mean that operators can quickly adapt the system to their specific needs. This flexibility, combined with the advanced features and technologies, positions the L129 Series as a leading choice for businesses seeking to optimize engine performance and enhance operational efficiency.

In summary, the Murphy L129 Series stands out as a sophisticated engine monitoring and control solution, backed by cutting-edge technology and robust features. With its focus on durability, accuracy, and user-friendliness, it serves as a vital component in the arsenal of tools needed to maintain engine health and drive operational success across various industries.