3.When restarting a saw in the work- piece, center the saw blade in the kerf, or cut, and check that saw teeth are not engaged into the material. If saw blade is binding, it may walk up or KICKBACK from the workpiece as the saw is restarted.

4.Support large panels to minimize the risk of blade pinching and KICK- BACK. Large panels tend to sag under their own weight. Supports must be placed under the panel on both sides, near the line of cut and near the edge of the panel.

5.Do not use dull or damaged blades. Unsharpened or improperly set blades produce narrow kerf causing excessive friction, blade binding and KICKBACK.

6.Blade depth and bevel adjusting lock- ing levers must be tight and secure before making cut. If blade adjustment shifts while cutting, it may cause binding and KICKBACK.

7.Use extra caution when making a “Pocket Cut” into existing walls or other blind areas. The protruding blade may cut objects that can cause

KICKBACK.

8.Set the depth of cut for no more than 1/8" to 1/4" greater than the thickness of the stock. The less blade exposed, the less chance of binding and KICK- BACK. Before cutting, be sure depth and bevel adjustments are tight.

9.Be cautious of pitchy, knotty, wet or warped stock. These are most likely to create pinching conditions and possible KICKBACK. Do not rip warped lumber. Avoid cutting nails.

10.Use a rip fence or edge guide when ripping. Guides improve control and reduce blade binding.

11.Stay alert. Any distraction can cause twisting or binding. Repetitive cuts may lull the user into careless movements.

General Operation

Always clamp the workpiece securely on a saw horse or bench (Fig. 11). See “APPLICA- TIONS” for the correct way to support your work in different situations.

Fig. 11

1.Draw a cutting line. Place the front of the shoe on the edge of the workpiece without making blade contact. Hold the handle with one hand and the front handle with the other (Fig. 12).

Fig. 12

2.Line up the sight line with your cutting line. Position your arms and body to resist KICKBACK.

3.To start the saw, push the

4.While cutting, keep the shoe flat against the workpiece and maintain a firm grip. Do not force the saw through the workpiece. Forcing a saw can cause

KICKBACK.

5.If making a partial cut, restarting in

6.If the saw binds and stalls, maintain a firm grip and release the trigger im- mediately. Hold the saw motionless in the workpiece until the blade comes to a complete stop.

7.After finishing a cut, be sure the lower guard closes and the blade comes to a complete stop before setting the saw down.

Electric Brake

This tool features an electric brake. The brake engages when the trigger is released, causing the blade to stop and allowing you to proceed with your work. Generally, the saw blade stops within two seconds. If the brake misses frequently, the saw needs servicing by an authorized MILWAUKEE service facil- ity. The brake is not a substitute for the guard, and you must always wait for the blade to stop completely before removing the saw from the workpiece.

Troubleshooting

If the blade does not follow a straight line:

•Teeth are dull. This is caused by hitting a hard object such as a nail or stone, dull- ing teeth on one side. The blade tends to cut to the side with the sharpest teeth.

•Shoe is out of line or bent

•Blade is bent

•Rip fence or guide is not being used

If the blade binds, smokes or turns blue from friction:

•Blade is dull

•Blade is on backwards

•Blade is bent

•Blade is dirty

•Workpiece is not properly supported

•Incorrect blade is being used

APPLICATIONS

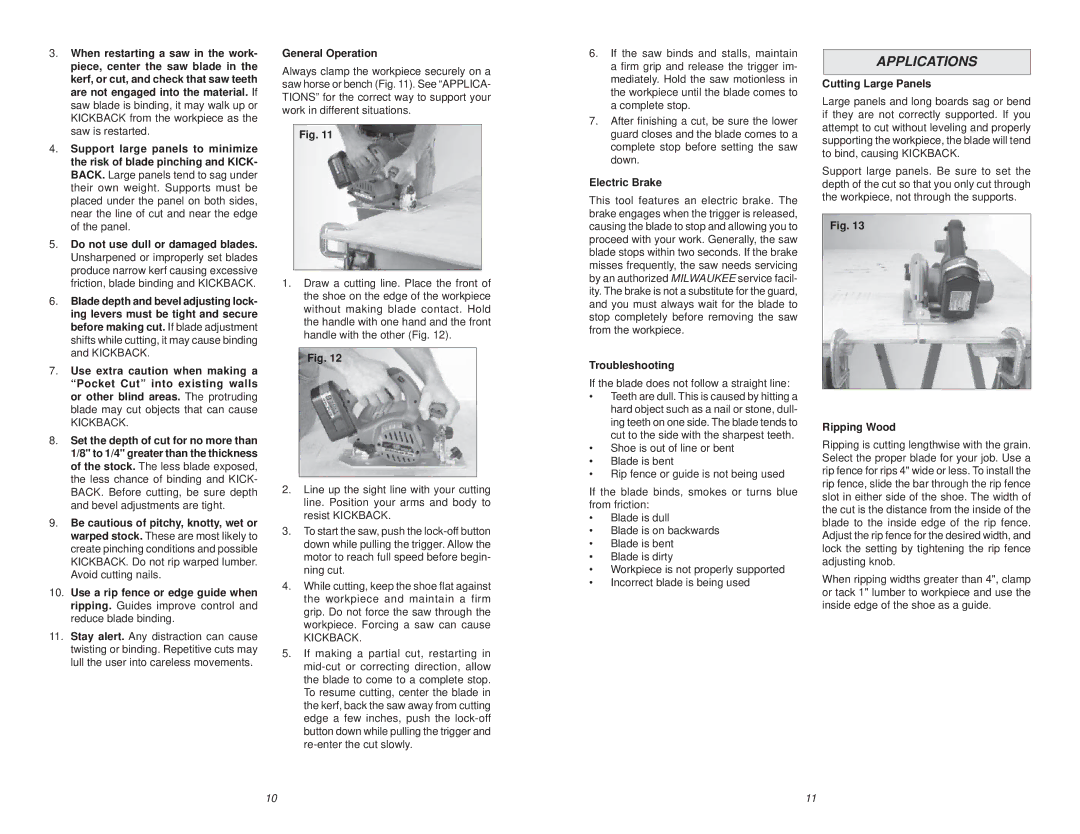

Cutting Large Panels

Large panels and long boards sag or bend if they are not correctly supported. If you attempt to cut without leveling and properly supporting the workpiece, the blade will tend to bind, causing KICKBACK.

Support large panels. Be sure to set the depth of the cut so that you only cut through the workpiece, not through the supports.

Fig. 13

Ripping Wood

Ripping is cutting lengthwise with the grain. Select the proper blade for your job. Use a rip fence for rips 4" wide or less. To install the rip fence, slide the bar through the rip fence slot in either side of the shoe. The width of the cut is the distance from the inside of the blade to the inside edge of the rip fence. Adjust the rip fence for the desired width, and lock the setting by tightening the rip fence adjusting knob.

When ripping widths greater than 4", clamp or tack 1" lumber to workpiece and use the inside edge of the shoe as a guide.

10 | 11 |