BB9O8O, BB9OOO, BB9O6O specifications

The New Holland BB9060, BB9080, and BB9000 series are a trio of advanced square balers designed to meet the demands of modern agriculture. These balers are engineered for efficiency, durability, and superior performance, making them essential tools for farmers and contractors who require high-quality bales for various applications.One of the standout features of the BB9000 series is the company’s innovative technology designed to optimize bale production. The balers are equipped with a unique crop feeding system that ensures a continuous flow of materials, enhancing the overall productivity during operation. This is complemented by high-capacity pick-up mechanisms, which effectively gather crop material while minimizing losses and ensuring efficient feeding into the baling chamber.

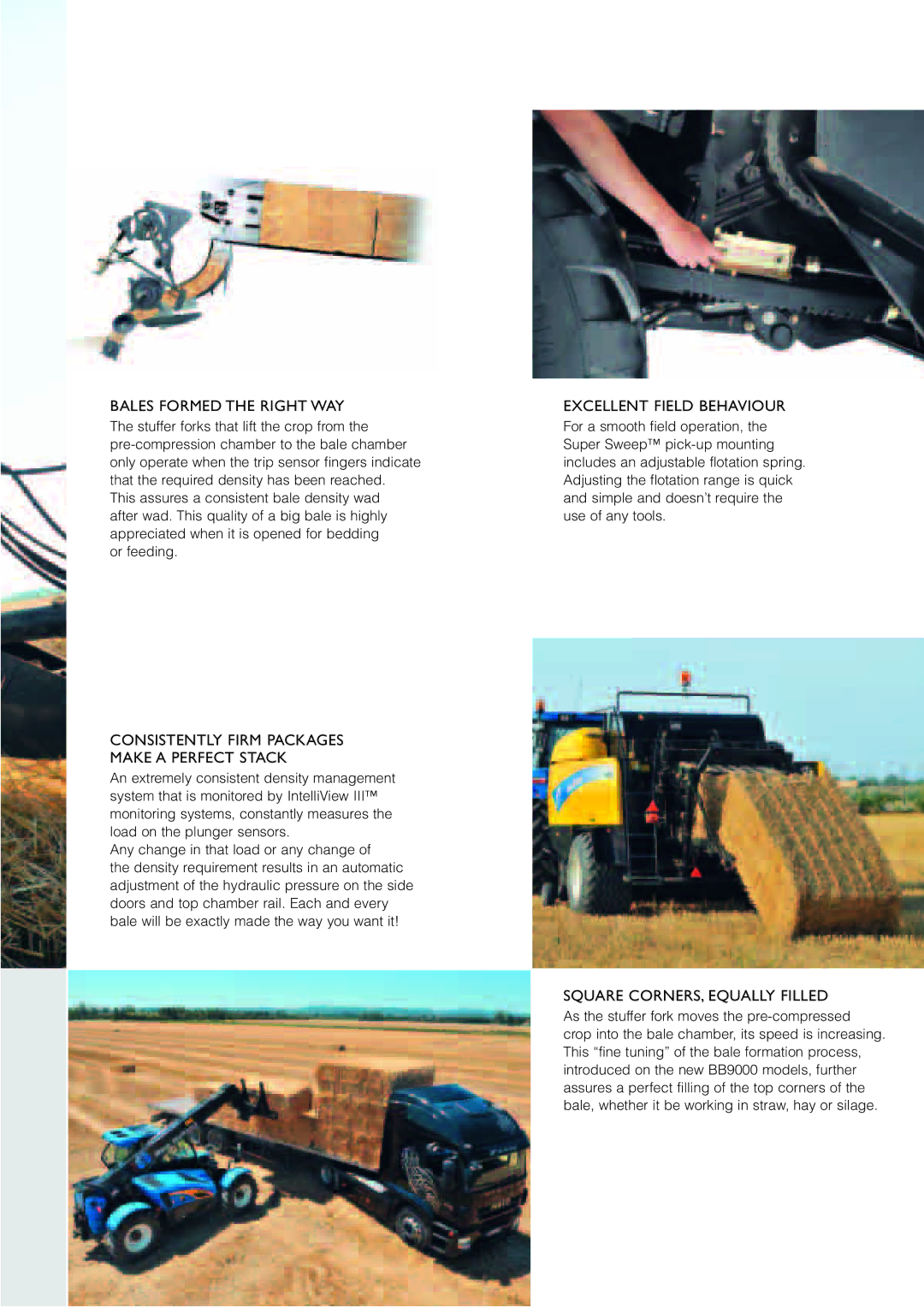

Another significant characteristic of the BB9060 and BB9080 models is their high-density baling capability. Farmers can create denser bales, which not only increases the storage efficiency but also reduces the number of trips needed for transportation, resulting in lower fuel and labor costs. This feature is particularly beneficial for operations that handle large volumes of straw, hay, or silage.

In terms of build quality, the BB9000 series is designed for robust operation. The balers feature a reinforced frame and heavy-duty components that can withstand the rigorous demands of fieldwork. Moreover, the balers are equipped with advanced knotters that ensure secure tying of bales, reducing the risk of knot failures and delivering consistent bale quality.

User comfort is also a top priority in the design of the BB9000 series. The models are fitted with an ergonomic control system that allows operators to manage all baler functions easily, enhancing usability during long working hours. Additionally, the large capacity of the bale chamber allows for longer run times with fewer stops for maintenance or adjustments.

In conclusion, the New Holland BB9060, BB9080, and BB9000 series balers represent the cutting edge of agricultural technology. With their efficient crop handling systems, high-density baling capabilities, exceptional durability, and user-friendly controls, these balers are poised to meet the evolving needs of the agricultural industry, delivering reliable performance in the toughest conditions. Farmers can depend on the BB9000 series for excellent productivity and superior build quality, ensuring optimal results in their baling operations.