10000 PPG specifications

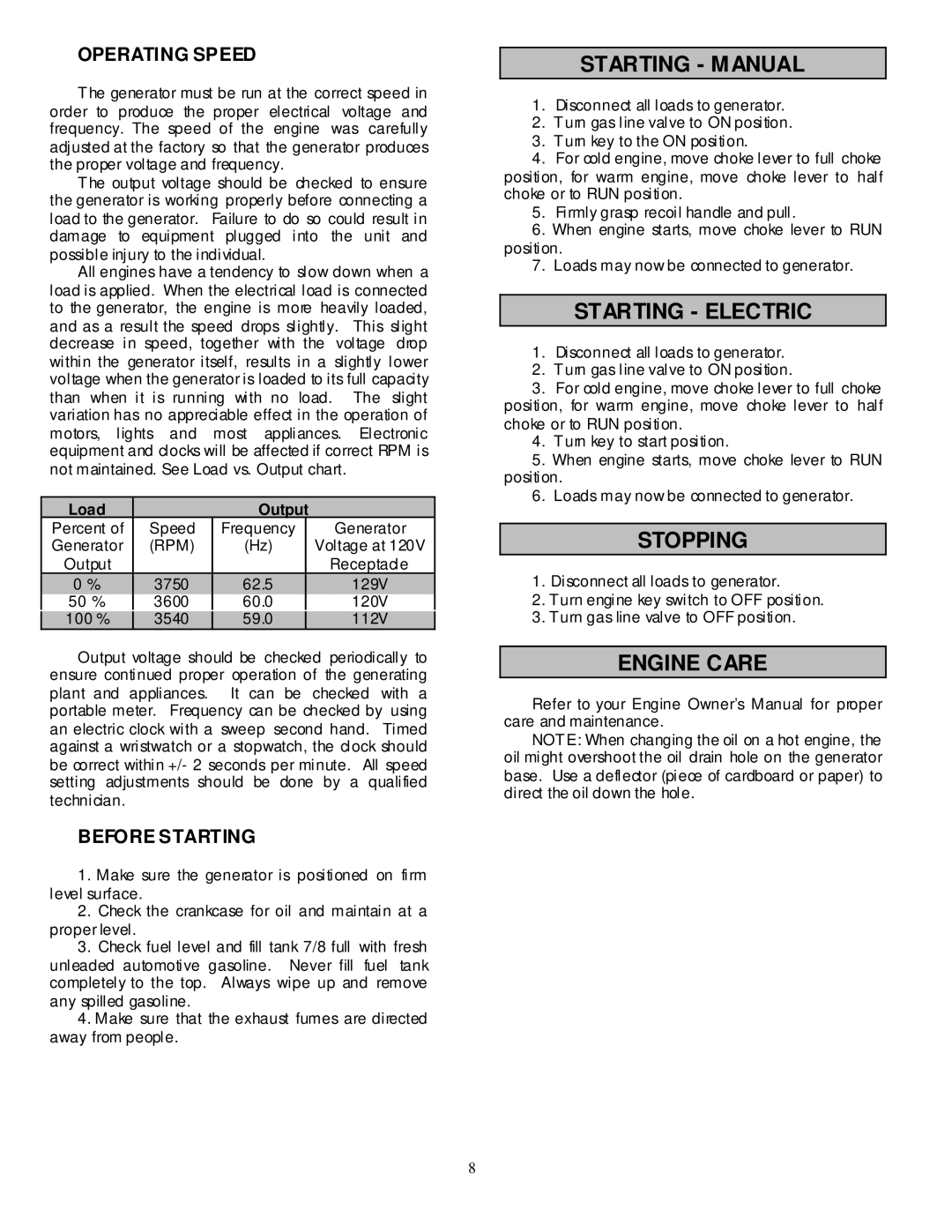

The North Star 10000 PPG is a cutting-edge power generation unit designed for both commercial and industrial applications. Built with the latest technologies in the realm of portable power generation, the North Star 10000 PPG stands out for its efficiency, durability, and ease of use.One of the main features of the North Star 10000 PPG is its robust engine. The unit is equipped with a powerful four-stroke engine that delivers an impressive output of 10,000 watts, making it suitable for various applications, from powering tools at a construction site to providing backup power for homes and businesses during outages. The engine has been engineered for optimal fuel efficiency, ensuring that users get the most out of every gallon of fuel consumed.

Another key characteristic is its advanced inverter technology. The North Star 10000 PPG uses a high-performance inverter system that produces clean, stable power suitable for sensitive electronics. This feature is especially beneficial for users who need to power devices such as computers, medical equipment, or any appliance that requires stable electrical input.

The design of the unit also incorporates a steel frame that provides enhanced protection against rugged conditions. Its rain-resistant feature means it can operate efficiently even in adverse weather, making it ideal for outdoor usage. The compact and portable nature of the unit allows for easy transport, with built-in wheels and a sturdy handle making it user-friendly for individuals on the go.

Safety is paramount in the design of the North Star 10000 PPG. The unit comes equipped with multiple safety features, including low-oil shut-off, overload protection, and noise reduction technology. This focus on safety ensures a reliable operation while minimizing the risk of accidents or failures during use.

Moreover, the North Star 10000 PPG has a user-friendly control panel that simplifies operation. With integrated display gauges showing power output and fuel levels, users can quickly assess the unit's performance at a glance. The model also boasts a long run time, providing extended operation without the need for frequent refueling.

Overall, the North Star 10000 PPG represents a significant advancement in portable power generation technology. Its combination of power, efficiency, safety features, and user-friendly design makes it a top choice for anyone in need of reliable power solutions, whether for emergency backup or routine use in various applications. As a versatile and powerful generator, it meets the needs of a diverse range of users.