Step 18. Store selected Decimal Point position

By pressing d momentarily the Decimal Point position will be stored and the instrument will go to the next menu item.

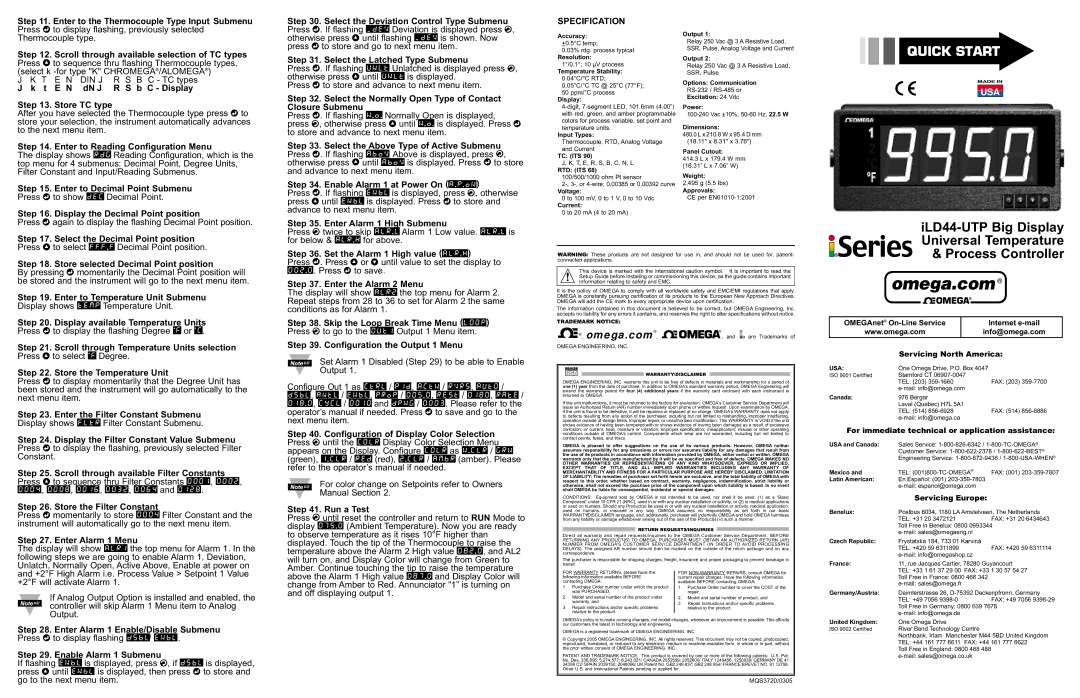

Step 19. Enter to Temperature Unit Submenu

Display shows TEMP Temperature Unit.

Step 20. Display available Temperature Units

Press d to display the flashing Degree °F or °C.

Step 21. Scroll through Temperature Units selection

Press b to select °F Degree.

Step 22. Store the Temperature Unit

Press d to display momentarily that the Degree Unit has been stored and the instrument will go automatically to the next menu item.

Step 23. Enter the Filter Constant Submenu

Display shows FLTR Filter Constant Submenu.

Step 24. Display the Filter Constant Value Submenu Press d to display the flashing, previously selected Filter Constant.

Step 25. Scroll through available Filter Constants

Press b to sequence thru Filter Constants 0001, 0002, 0004, 0008, 0016, 0032, 0064 and 0128.

Step 26. Store the Filter Constant

Press d momentarily to store 0004 Filter Constant and the instrument will automatically go to the next menu item.

Step 27. Enter Alarm 1 Menu

The display will show ALR1 the top menu for Alarm 1. In the following steps we are going to enable Alarm 1, Deviation, Unlatch, Normally Open, Active Above, Enable at power on and +2°F High Alarm i.e. Process Value > Setpoint 1 Value +2°F will activate Alarm 1.

If Analog Output Option is installed and enabled, the controller will skip Alarm 1 Menu item to Analog Output.

Step 28. Enter Alarm 1 Enable/Disable Submenu

Press d to display flashing DSBL/ ENBL.

Step 29. Enable Alarm 1 Submenu

If flashing ENBL is displayed, press a, if DSBL is displayed, press b until ENBL is displayed, then press d to store and go to the next menu item.

Step 36. Set the Alarm 1 High value (ALR.H)

Press d. Press b or c until value to set the display to

002.0. Press d to save.

Step 37. Enter the Alarm 2 Menu

The display will show ALR2 the top menu for Alarm 2. Repeat steps from 28 to 36 to set for Alarm 2 the same conditions as for Alarm 1.

Step 38. Skip the Loop Break Time Menu (LOOP)

Press a to go to the OUT1 Output 1 Menu item.

Step 39. Configuration the Output 1 Menu

Set Alarm 1 Disabled (Step 29) to be able to Enable Output 1.

Configure Out 1 as CTRL / PID, ACTN / RVRS, AUTO / DSBL, ANTL / ENBL, PRoP / 005.0, REST / 0180, RATE /

018.0, CYCL / 0010 and DPNG / 0003. Please refer to the operator’s manual if needed. Press d to save and go to the next menu item.

Step 40. Configuration of Display Color Selection

Press a until the COLR Display Color Selection Menu appears on the Display. Configure COLR as N.CLR / GRN (green), 1.CLR / RED (red), 2.CLR / AMBR (amber). Please

refer to the operator’s manual if needed.

For color change on Setpoints refer to Owners Manual Section 2.

Step 41. Run a Test

Press a until reset the controller and return to RUN Mode to display 075.0 (Ambient Temperature). Now you are ready to observe temperature as it rises 10°F higher than displayed. Touch the tip of the Thermocouple to raise the temperature above the Alarm 2 High value 082.0, and AL2 will turn on, and Display Color will change from Green to

Amber. Continue touching the tip to raise the temperature above the Alarm 1 High value 087.0 and Display Color will

change from Amber to Red. Annunciator “1” is turning on and off displaying output 1.

WARNING: These products are not designed for use in, and should not be used for, patient- connected applications.

This device is marked with the international caution symbol. It is important to read the Setup Guide before installing or commissioning this device, as the guide contains important information relating to safety and EMC.

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.

TRADEMARK NOTICE:

® , omega.com® ,

® , omega.com® ,

® , and

® , and  ® are Trademarks of

® are Trademarks of

OMEGA ENGINEERING, INC.

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of one (1) year from the date of purchase. In addition to OMEGA’s standard warranty period, OMEGA Engineering will extend the warranty period for four (4) additional years if the warranty card enclosed with each instrument is returned to OMEGA.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components which wear are not warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

| FOR WARRANTY RETURNS, please have the | FOR NON-WARRANTY REPAIRS, consult OMEGA for |

| following information available BEFORE | current repair charges. Have the following information |

| contacting OMEGA: | available BEFORE contacting OMEGA: |

| 1. | Purchase Order number under which the product | 1. | Purchase Order number to cover the COST of the |

| | was PURCHASED, | | repair, |

| 2. | Model and serial number of the product under | 2. | Model and serial number of product, and |

| | warranty, and | 3. | Repair instructions and/or specific problems |

| 3. | Repair instructions and/or specific problems |

| | relative to the product. |

| | relative to the product. | | |

| | | |

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

©Copyright 2005 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

PATENT AND TRADEMARK NOTICE: This product is covered by one or more of the following patents: U.S. Pat. No. Des. 336,895; 5,274,577; 6,243,021/ CANADA 2052599; 2052600/ ITALY 1249456; 1250938/ GERMANY DE 41 34398 C2/ SPAIN 2039150; 2048066/ UK Patent No. GB2 249 837; GB2 248 954/ FRANCE BREVET NO. 91 12756. Other U.S. and International Patents pending or applied for.

MQS3720/0305