IMPSW180T

PSW-180 TEFLON SERIES

Differential Pressure Switches

I N S T R U C T I O N | M3569/0500 | |

S H E E T | ||

| ||

|

|

GENERAL

Part I - Installation

Tools Needed

Applicable Screwdriver Flaretek® tubing cutter

MOUNTING

LOCATE SWITCH WHERE VIBRATION, SHOCK, AND AMBIENT TEMPERATURE FLUCTUATIONS ARE MINIMAL.

The control can be mounted in any position. Locate where ambient temperature is above 30°F and below 160°F.

Surface Mounting

Insert two #6 screws through mounting ear holes on 2” centers (recommended mounting for maximum vibration resistance). Follow directions for making pressure connection.

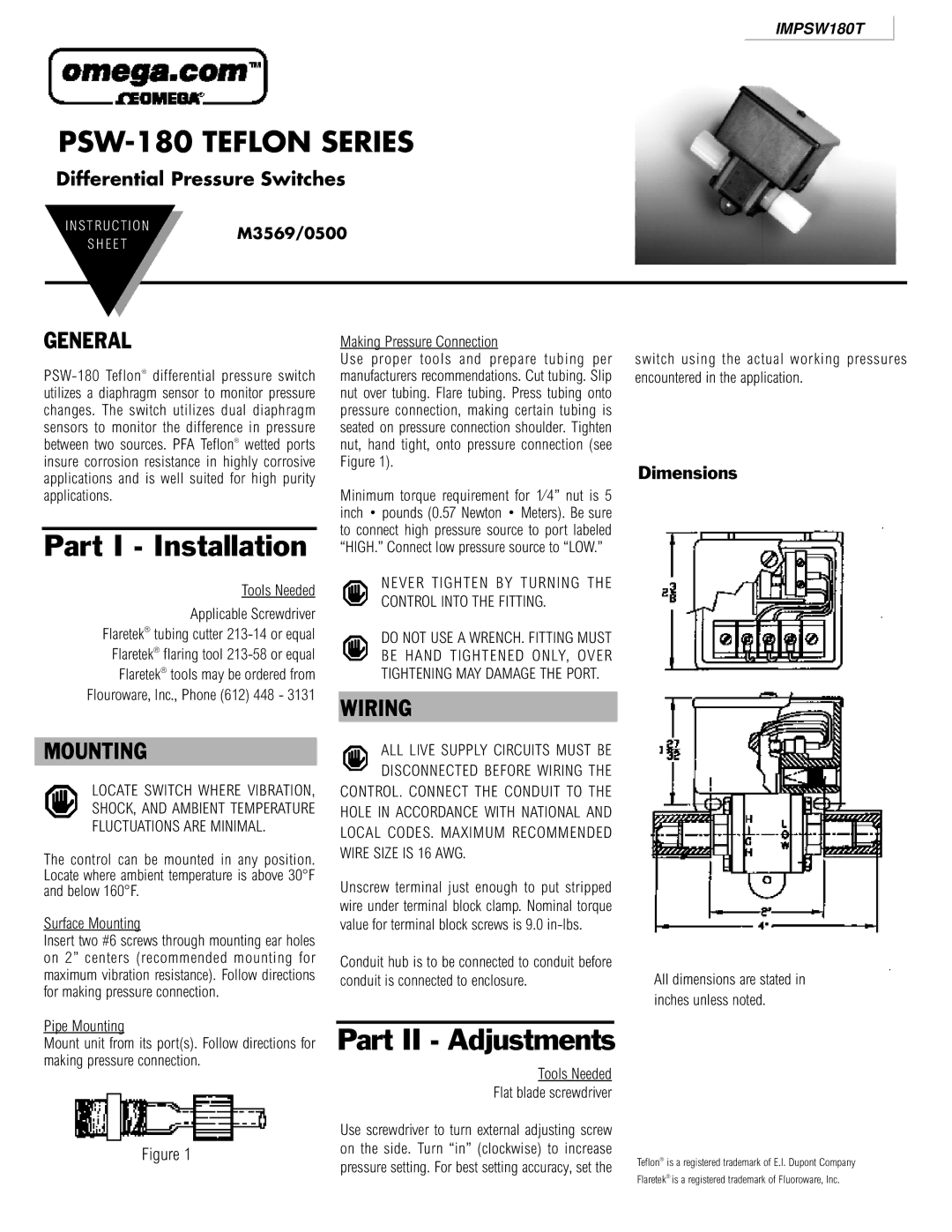

Making Pressure Connection

Use proper tools and prepare tubing per manufacturers recommendations. Cut tubing. Slip nut over tubing. Flare tubing. Press tubing onto pressure connection, making certain tubing is seated on pressure connection shoulder. Tighten nut, hand tight, onto pressure connection (see Figure 1).

Minimum torque requirement for 1⁄4” nut is 5 inch • pounds (0.57 Newton • Meters). Be sure to connect high pressure source to port labeled “HIGH.” Connect low pressure source to “LOW.”

NEVER TIGHTEN BY TURNING THE CONTROL INTO THE FITTING.

DO NOT USE A WRENCH. FITTING MUST BE HAND TIGHTENED ONLY, OVER TIGHTENING MAY DAMAGE THE PORT.

WIRING

ALL LIVE SUPPLY CIRCUITS MUST BE DISCONNECTED BEFORE WIRING THE CONTROL. CONNECT THE CONDUIT TO THE HOLE IN ACCORDANCE WITH NATIONAL AND LOCAL CODES. MAXIMUM RECOMMENDED

WIRE SIZE IS 16 AWG.

Unscrew terminal just enough to put stripped wire under terminal block clamp. Nominal torque value for terminal block screws is 9.0

Conduit hub is to be connected to conduit before conduit is connected to enclosure.

switch using the actual working pressures encountered in the application.

Dimensions

All dimensions are stated in inches unless noted.

Pipe Mounting

Mount unit from its port(s). Follow directions for making pressure connection.

Figure 1

Part II - Adjustments

Tools Needed |

| |

Flat blade screwdriver |

| |

Use screwdriver to turn external adjusting screw |

| |

on the side. Turn “in” (clockwise) to increase | Teflon® is a registered trademark of E.I. Dupont Company | |

pressure setting. For best setting accuracy, set the | ||

|

Flaretek® is a registered trademark of Fluoroware, Inc.