PX2670 specifications

The Omega Engineering PX2670 is a high-performance pressure transducer that caters to a wide array of industrial applications. Known for its reliability and precision, the PX2670 seamlessly integrates into various systems, ensuring accurate pressure measurements under diverse conditions.One of the standout features of the PX2670 is its robust construction. The device is designed to withstand harsh environments, making it suitable for industries such as oil and gas, pharmaceuticals, and food processing. With a stainless steel housing, the PX2670 offers excellent resistance to corrosion and can operate in extreme temperatures, enhancing its durability and longevity in demanding situations.

The PX2670 utilizes advanced sensing technologies, which contribute to its impressive accuracy and repeatability. It boasts a high overpressure capability, ensuring that it can handle spikes in pressure without compromising measurement integrity. This is particularly important in dynamic systems where pressure fluctuations can be common. The device’s wide pressure range, from vacuum levels to several thousand psi, allows for versatility in application, catering to both low and high-pressure environments.

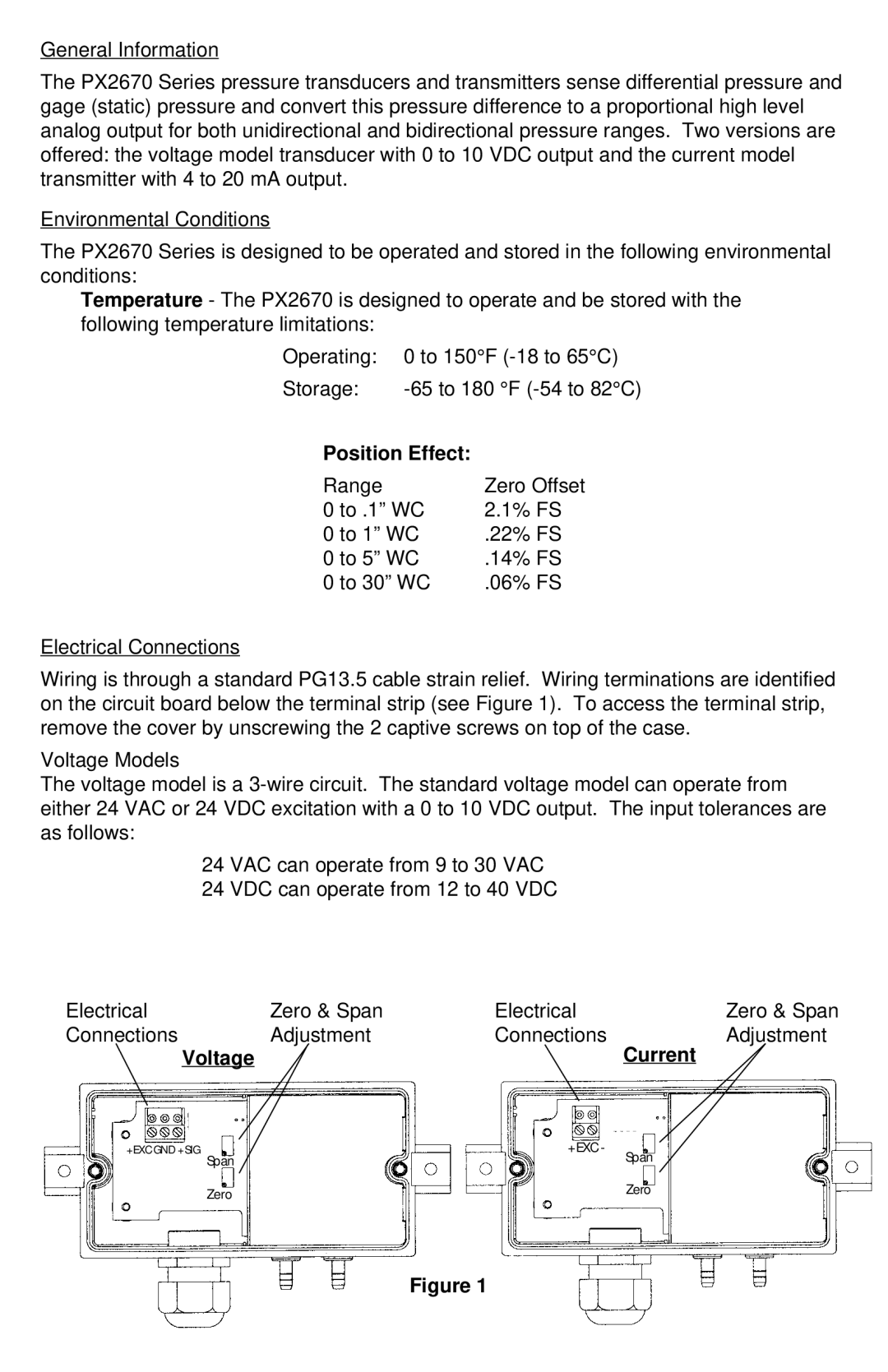

Another notable characteristic of the PX2670 is its output options. The transducer can be configured to provide analog signals, such as 4-20 mA and 0-10 V, which are standard in process control systems. This flexibility enables easy integration into existing setups, facilitating quick installation and deployment.

The PX2670 also features a highly responsive performance with minimal hysteresis, ensuring that the readings are consistently precise. Additionally, it is equipped with temperature compensation technology, which helps maintain accuracy across varying thermal conditions, a common challenge in pressure measurement.

Safety and compliance are also paramount in industrial settings, and the PX2670 meets various international standards, ensuring it adheres to regulations for quality and safety.

In summary, the Omega Engineering PX2670 is a highly efficient, versatile, and reliable pressure transducer. With its durable construction, advanced sensing technology, a broad range of output options, and excellent temperature compensation, it stands out as a prime choice for professionals seeking precise pressure measurement solutions in challenging environments.