Installation

The

Thread the unit into the tank and tighten until a good, no leak seal is obtained. Make sure that the arrows molded on the body casting and printed on the label are pointed vertically downward.

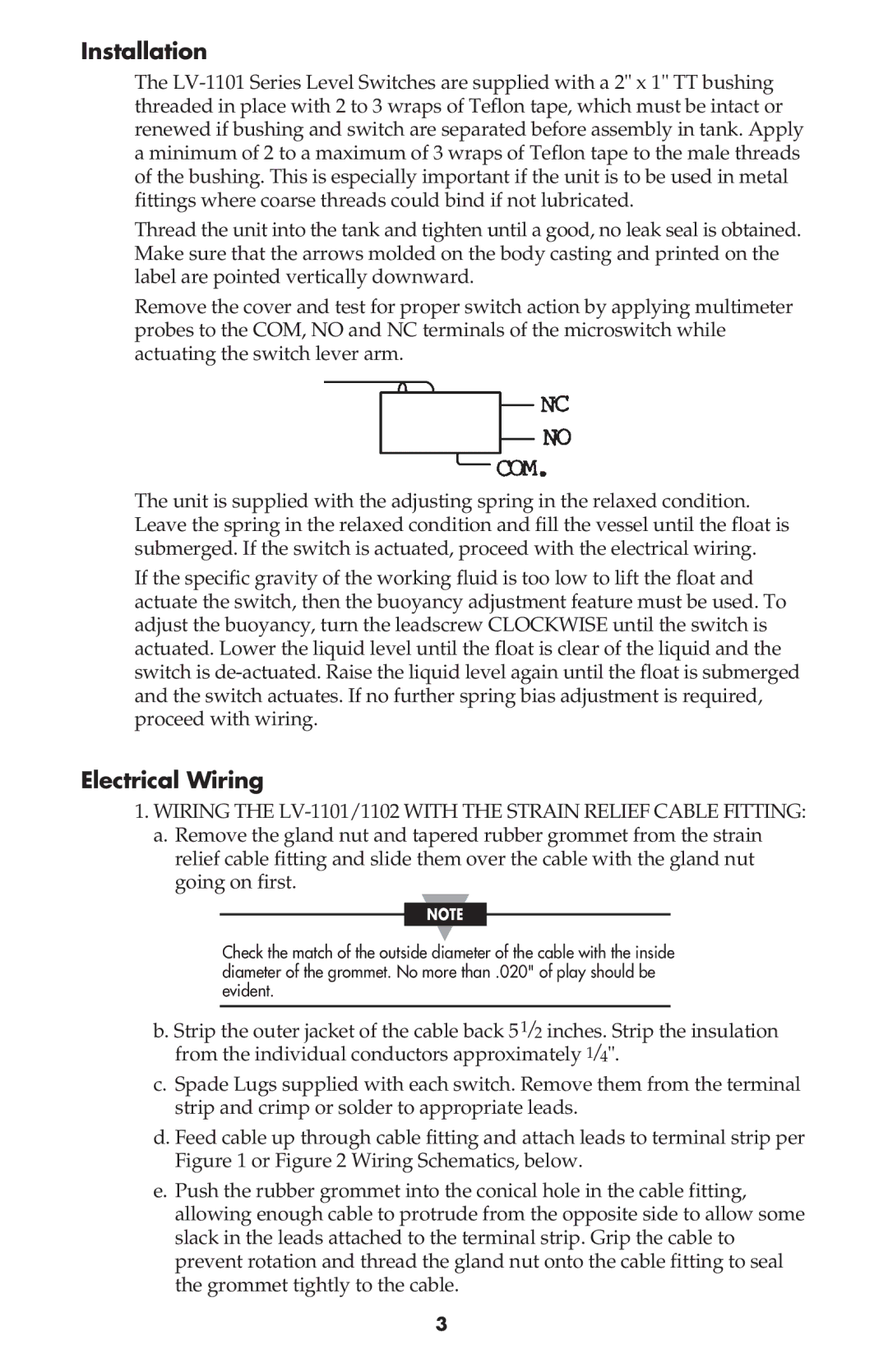

Remove the cover and test for proper switch action by applying multimeter probes to the COM, NO and NC terminals of the microswitch while actuating the switch lever arm.

The unit is supplied with the adjusting spring in the relaxed condition. Leave the spring in the relaxed condition and fill the vessel until the float is submerged. If the switch is actuated, proceed with the electrical wiring.

If the specific gravity of the working fluid is too low to lift the float and actuate the switch, then the buoyancy adjustment feature must be used. To adjust the buoyancy, turn the leadscrew CLOCKWISE until the switch is actuated. Lower the liquid level until the float is clear of the liquid and the switch is

Electrical Wiring

1.WIRING THE

a.Remove the gland nut and tapered rubber grommet from the strain relief cable fitting and slide them over the cable with the gland nut going on first.

NOTE

Check the match of the outside diameter of the cable with the inside diameter of the grommet. No more than .020" of play should be evident.

b. Strip the outer jacket of the cable back 51/2 inches. Strip the insulation from the individual conductors approximately 1/4".

c.Spade Lugs supplied with each switch. Remove them from the terminal strip and crimp or solder to appropriate leads.

d.Feed cable up through cable fitting and attach leads to terminal strip per Figure 1 or Figure 2 Wiring Schematics, below.

e.Push the rubber grommet into the conical hole in the cable fitting, allowing enough cable to protrude from the opposite side to allow some slack in the leads attached to the terminal strip. Grip the cable to prevent rotation and thread the gland nut onto the cable fitting to seal the grommet tightly to the cable.

3