Installation Instructions | OmniProx™ Reader |

Model Series OP10/20/30/40/45/90 | |

| K5336 Rev. 9, |

WHAT IS THE Honeywell OmniProx™ READER?

The OmniProx Reader is an RFID proximity card reader to be installed for use with access control systems.

These installation instructions contain the following information:

•Mounting Instructions

•Connecting the reader to the host

•Testing and operation of the reader

Visit www.omniprox.com for the latest information and technical support.

HOW TO MOUNT THE READER

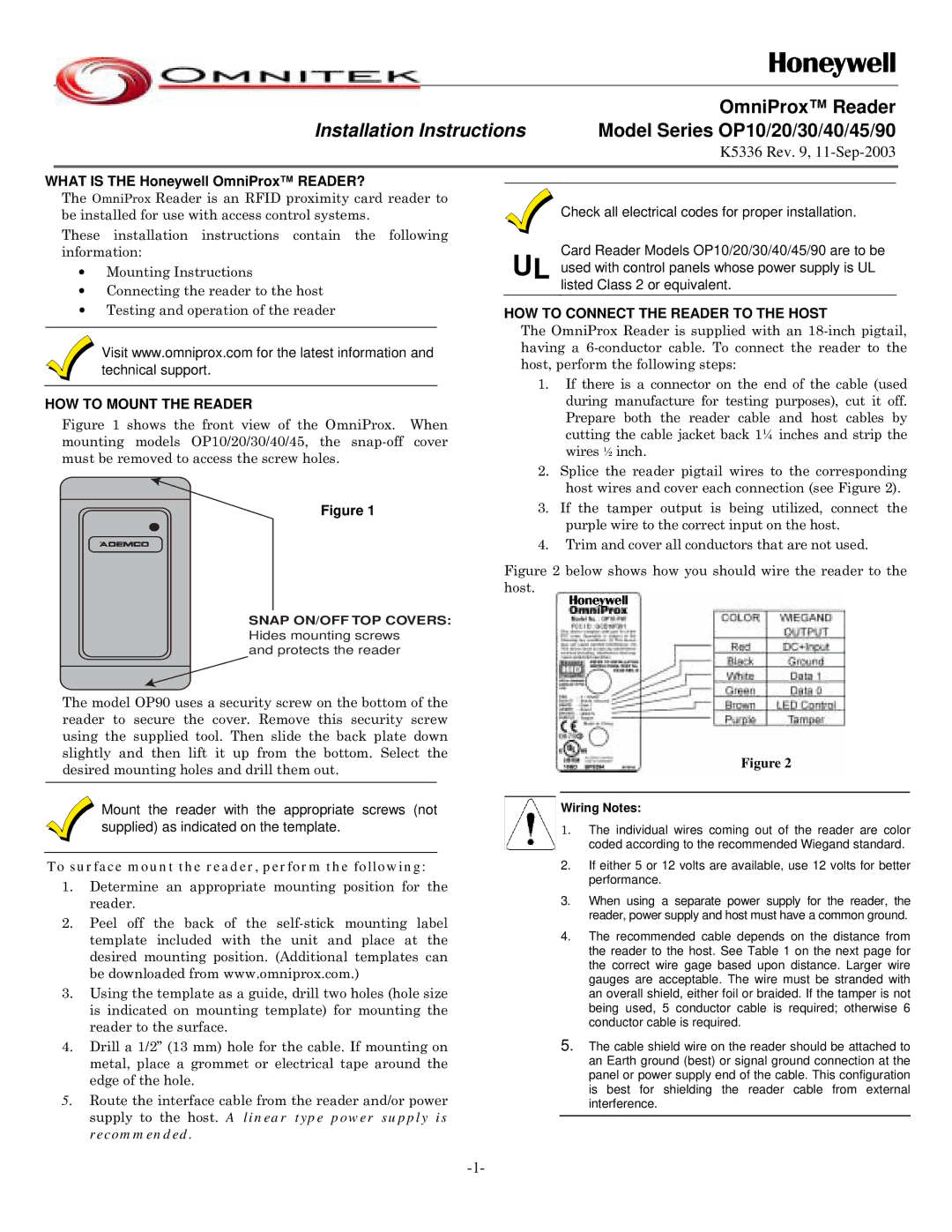

Figure 1 shows the front view of the OmniProx. When mounting models OP10/20/30/40/45, the snap-off cover must be removed to access the screw holes.

Figure 1

®

Check all electrical codes for proper installation.

Card Reader Models OP10/20/30/40/45/90 are to be UL used with control panels whose power supply is UL

listed Class 2 or equivalent.

HOW TO CONNECT THE READER TO THE HOST

The OmniProx Reader is supplied with an

1.If there is a connector on the end of the cable (used during manufacture for testing purposes), cut it off. Prepare both the reader cable and host cables by cutting the cable jacket back 1¼ inches and strip the wires ½ inch.

2.Splice the reader pigtail wires to the corresponding host wires and cover each connection (see Figure 2).

3.If the tamper output is being utilized, connect the purple wire to the correct input on the host.

4.Trim and cover all conductors that are not used.

Figure 2 below shows how you should wire the reader to the host.

SNAP ON/OFF TOP COVERS:

Hides mounting screws

and protects the reader

The model OP90 uses a security screw on the bottom of the reader to secure the cover. Remove this security screw using the supplied tool. Then slide the back plate down slightly and then lift it up from the bottom. Select the desired mounting holes and drill them out.

Mount the reader with the appropriate screws (not supplied) as indicated on the template.

To surface mount the reader, perform the following:

1.Determine an appropriate mounting position for the reader.

2.Peel off the back of the

3.Using the template as a guide, drill two holes (hole size is indicated on mounting template) for mounting the reader to the surface.

4.Drill a 1/2” (13 mm) hole for the cable. If mounting on metal, place a grommet or electrical tape around the edge of the hole.

5.Route the interface cable from the reader and/or power supply to the host. A linear type power supply is recommended.

Figure 2

Wiring Notes:

1.The individual wires coming out of the reader are color coded according to the recommended Wiegand standard.

2.If either 5 or 12 volts are available, use 12 volts for better performance.

3.When using a separate power supply for the reader, the reader, power supply and host must have a common ground.

4.The recommended cable depends on the distance from the reader to the host. See Table 1 on the next page for the correct wire gage based upon distance. Larger wire gauges are acceptable. The wire must be stranded with an overall shield, either foil or braided. If the tamper is not being used, 5 conductor cable is required; otherwise 6 conductor cable is required.

5.The cable shield wire on the reader should be attached to an Earth ground (best) or signal ground connection at the panel or power supply end of the cable. This configuration is best for shielding the reader cable from external interference.