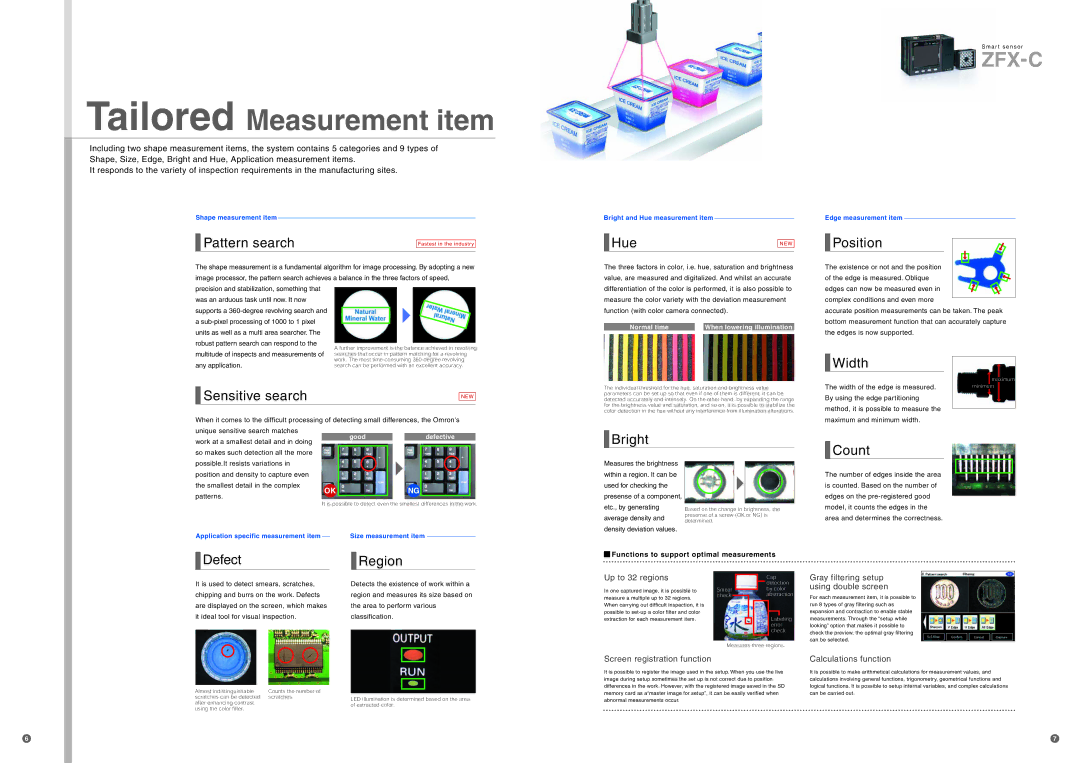

Tailored Measurement item

Including two shape measurement items, the system contains 5 categories and 9 types of Shape, Size, Edge, Bright and Hue, Application measurement items.

It responds to the variety of inspection requirements in the manufacturing sites.

Shape measurement item

Pattern search | Fastest in the industry |

The shape measurement is a fundamental algorithm for image processing. By adopting a new image processor, the pattern search achieves a balance in the three factors of speed, precision and stabilization, something that

was an arduous task until now. It now supports a

Sensitive search

When it comes to the difficult processing of detecting small differences, the Omron's unique sensitive search matches

Bright and Hue measurement item

HueNEW

The three factors in color, i.e. hue, saturation and brightness value, are measured and digitalized. And whilst an accurate differentiation of the color is performed, it is also possible to measure the color variety with the deviation measurement function (with color camera connected).

Normal time |

| When lowering illumination |

The individual threshold for the hue, saturation and brightness value parameters can be set up so that even if one of them is different, it can be detected accurately and intensely. On the other hand, by expanding the range for the brightness value and saturation, and so on, it is possible to stabilize the color detection in the hue without any interference from illumination alterations.

S m a r t s e n s o r

ZFX-C

Edge measurement item

Position

The existence or not and the position

of the edge is measured. Oblique edges can now be measured even in complex conditions and even more

accurate position measurements can be taken. The peak bottom measurement function that can accurately capture the edges is now supported.

| Width |

|

|

| |

|

|

|

| ||

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| maximum | |

The width of the edge is measured. | minimum |

|

| ||

By using the edge partitioning |

|

|

| ||

method, it is possible to measure the |

|

|

| ||

|

|

| |||

maximum and minimum width. |

|

|

| ||

work at a smallest detail and in doing |

| good |

|

| defective | ||

|

|

|

|

|

|

| |

so makes such detection all the more |

|

|

| ||||

Bright

Count

possible.It resists variations in |

|

|

|

|

|

| ||

position and density to capture even |

|

|

|

|

|

| ||

the smallest detail in the complex |

| NG | ||||||

| OK |

| ||||||

patterns. |

|

|

|

|

|

| ||

| It is possible to detect even the smallest differences in the work. | |||||||

Application specific measurement item |

|

| Size measurement item |

|

|

| ||

|

|

| ||||||

Measures the brightness within a region. It can be used for checking the presense of a component, etc., by generating average density and density deviation values.

Based on the change in brightness, the presense of a screw (OK or NG) is determined.

The number of edges inside the area is counted. Based on the number of edges on the

| Defect |

|

| Region |

It is used to detect smears, scratches, | Detects the existence of work within a | |||

chipping and burrs on the work. Defects | region and measures its size based on | |||

are displayed on the screen, which makes | the area to perform various | |||

it ideal tool for visual inspection. | classification. | |||

Almost indistinguishable | Counts the number of |

|

scratches can be detected | scratches | LED illumination is determined based on the area |

after enhancing contrast |

| |

| of extracted color. | |

using the color filter. |

| |

|

|

![]() Functions to support optimal measurements

Functions to support optimal measurements

Up to 32 regions |

|

|

|

|

|

|

| Cap | ||

|

|

|

|

|

|

|

| detection | ||

In one captured image, it is possible to | Smear |

|

|

|

|

| by color | |||

|

|

|

| |||||||

measure a multiple up to 32 regions. | check |

|

|

| abstraction | |||||

|

|

|

|

|

|

|

|

|

| |

When carrying out difficult inspection, it is |

|

|

|

|

|

|

|

|

|

|

possible to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

extraction for each measurement item. |

|

|

|

|

|

|

|

| Labeling | |

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| error | |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| check | |

|

|

|

|

|

|

|

|

| ||

| Measures three regions. | |||||||||

Screen registration function

It is possible to register the image used in the setup. When you use the live image during setup sometimes the set up is not correct due to position differences in the work. However, with the registered image saved in the SD memory card as a“master image for setup”, it can be easily verified when abnormal measurements occur.

Gray filtering setup using double screen

For each measurement item, it is possible to run 8 types of gray filtering such as expansion and contraction to enable stable measurements. Through the “setup while looking” option that makes it possible to check the preview, the optimal gray filtering can be selected.

Calculations function

It is possible to make arithmetical calculations for measurement values, and calculations involving general functions, trigonometry, geometrical functions and logical functions. It is possible to setup internal variables, and complex calculations can be carried out.

6 | 7 |