To Adjust or Replace Brush

WARNING: Unplug cord from electrical outlet before servicing.

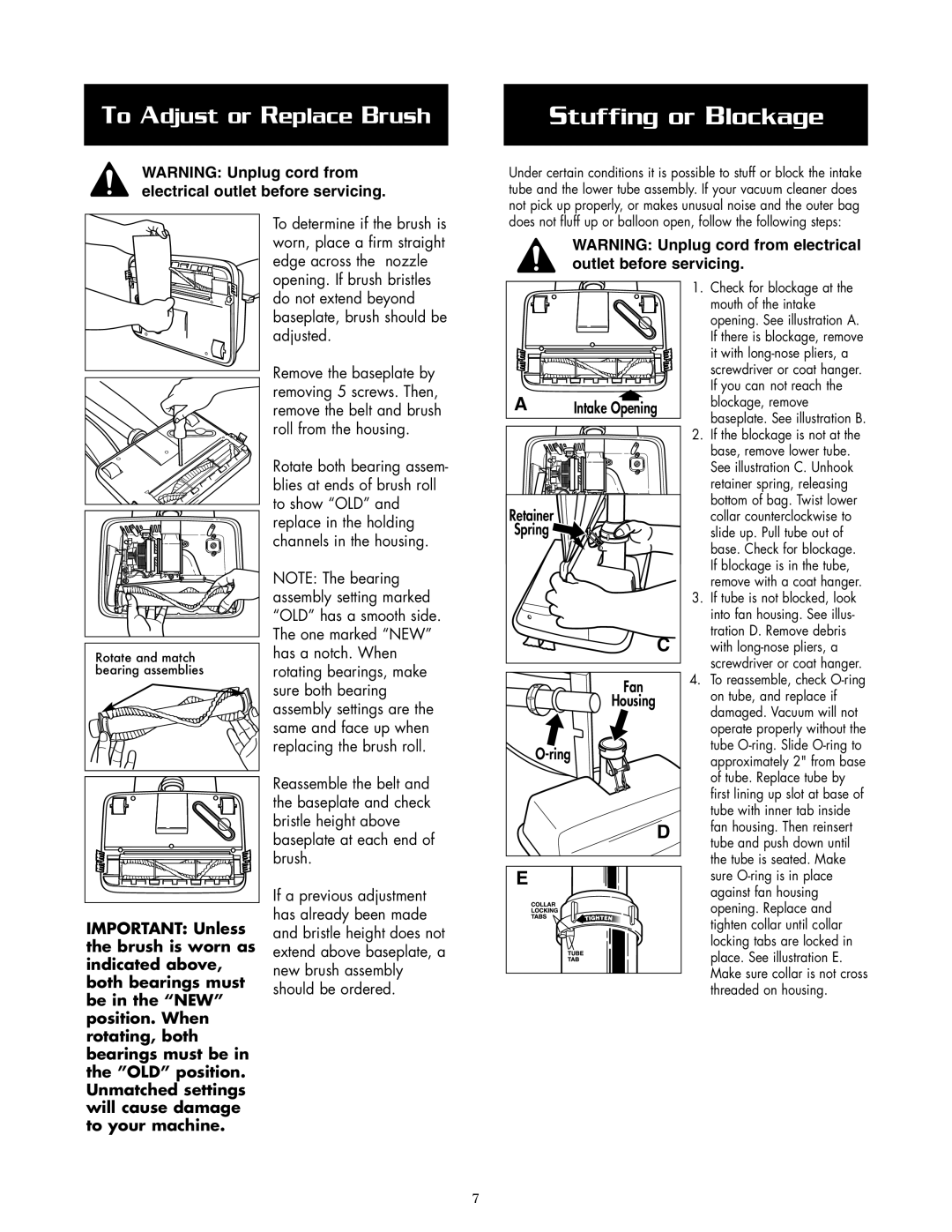

Stuffing or Blockage

Under certain conditions it is possible to stuff or block the intake tube and the lower tube assembly. If your vacuum cleaner does not pick up properly, or makes unusual noise and the outer bag

To determine if the brush is worn, place a firm straight edge across the nozzle opening. If brush bristles

does not fluff up or balloon open, follow the following steps:

WARNING: Unplug cord from electrical outlet before servicing.

Rotate and match |

bearing assemblies |

do not extend beyond baseplate, brush should be adjusted.

Remove the baseplate by removing 5 screws. Then, remove the belt and brush roll from the housing.

Rotate both bearing assem- blies at ends of brush roll to show “OLD” and replace in the holding channels in the housing.

NOTE: The bearing assembly setting marked “OLD” has a smooth side. The one marked “NEW” has a notch. When rotating bearings, make sure both bearing assembly settings are the same and face up when replacing the brush roll.

A | ➧ |

Intake Opening | |

Retainer |

|

Spring |

|

| C |

| Fan |

| Housing |

|

1. | Check for blockage at the |

| mouth of the intake |

| opening. See illustration A. |

| If there is blockage, remove |

| it with |

| screwdriver or coat hanger. |

| If you can not reach the |

| blockage, remove |

| baseplate. See illustration B. |

2. | If the blockage is not at the |

| base, remove lower tube. |

| See illustration C. Unhook |

| retainer spring, releasing |

| bottom of bag. Twist lower |

| collar counterclockwise to |

| slide up. Pull tube out of |

| base. Check for blockage. |

| If blockage is in the tube, |

| remove with a coat hanger. |

3. | If tube is not blocked, look |

| into fan housing. See illus- |

| tration D. Remove debris |

| with |

| screwdriver or coat hanger. |

4. | To reassemble, check |

| on tube, and replace if |

| damaged. Vacuum will not |

| operate properly without the |

| tube |

| approximately 2" from base |

IMPORTANT: Unless the brush is worn as indicated above, both bearings must be in the “NEW” position. When rotating, both bearings must be in the ”OLD” position. Unmatched settings will cause damage to your machine.

Reassemble the belt and the baseplate and check bristle height above baseplate at each end of brush.

If a previous adjustment has already been made and bristle height does not extend above baseplate, a new brush assembly should be ordered.

D |

E |

of tube. Replace tube by |

first lining up slot at base of |

tube with inner tab inside |

fan housing. Then reinsert |

tube and push down until |

the tube is seated. Make |

sure |

against fan housing |

opening. Replace and |

tighten collar until collar |

locking tabs are locked in |

place. See illustration E. |

Make sure collar is not cross |

threaded on housing. |

7