HCCA 15.4, HCCA 12.04, HCCA 10.4, HCCA 12.2, HCCA 15.2 specifications

Orion Car Audio has long been synonymous with high-performance sound systems, and its HCCA subwoofer series exemplifies that tradition. The HCCA subwoofers, including models HCCA 12.04, HCCA 10.2, HCCA 15.4, HCCA 12.2, and HCCA 10.4, are designed to deliver exceptional audio quality and robust power handling capabilities.One of the standout features of the HCCA series is its impressive power handling. The HCCA 12.04, for instance, can handle up to 1200 watts RMS, making it a formidable contender for serious bass enthusiasts. Similarly, the HCCA 10.2 and 10.4 models handle 1000 watts RMS each, while the HCCA 15.4 excels with an astounding 1500 watts RMS, producing deep, resonant bass that can be felt as much as it can be heard.

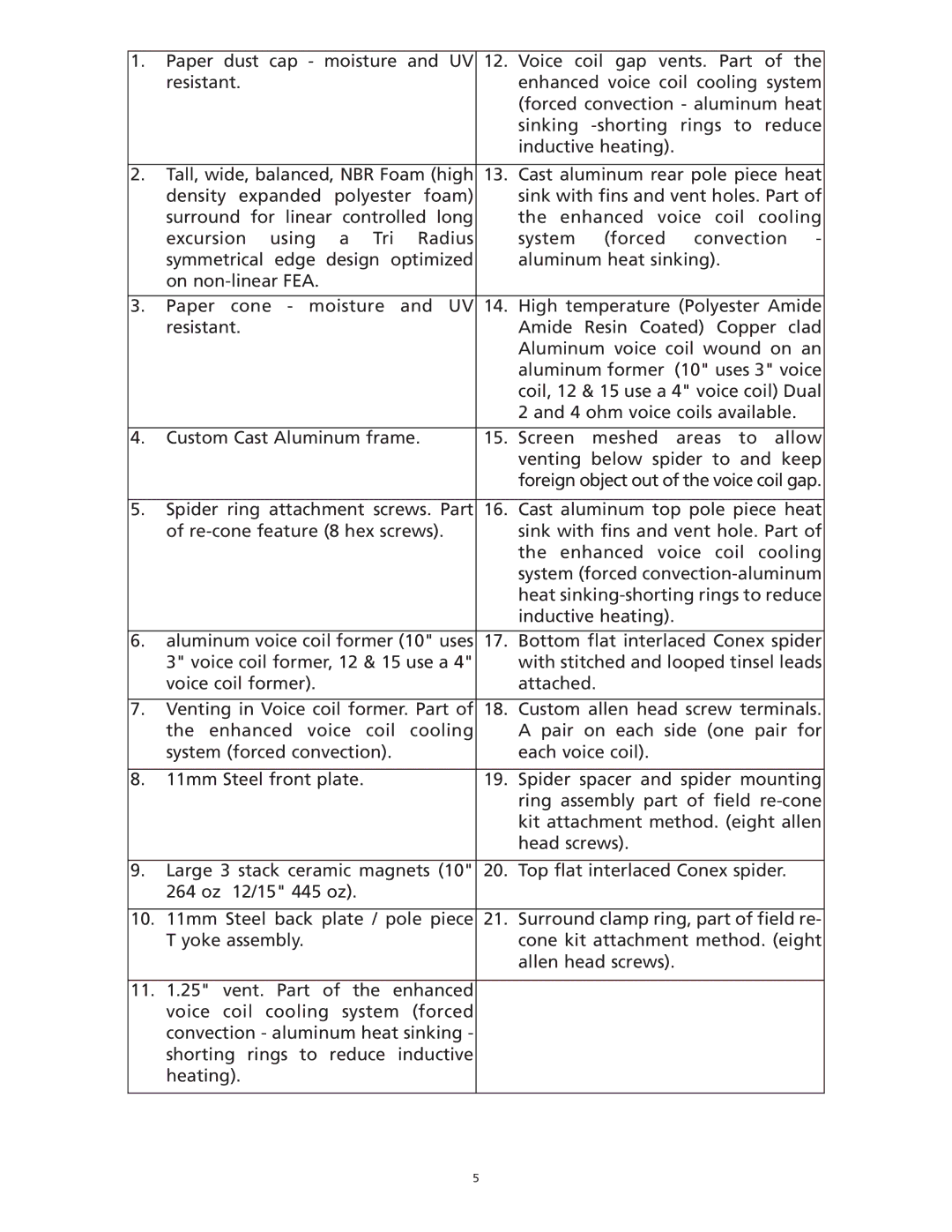

At the heart of these subwoofers is Orion's advanced technology, which includes a dual 2-ohm voice coil design for the HCCA 12.04 and HCCA 15.4, allowing for versatile wiring configurations that enhance performance and efficiency. The high-temperature voice coils ensure that the subwoofers can sustain prolonged use without overheating, making them ideal for competitive environments or long drives with the music up loud.

The construction of the HCCA series is equally impressive. Each subwoofer features a heavy-duty cast aluminum frame that adds stability and durability. The polypropylene cone is designed for optimal cone movement and sound wave propagation. It also features an oxidation-resistant coating, ensuring longevity and performance in various environmental conditions.

Another key characteristic of the HCCA subwoofers is their versatility in tuning. They can be used in a variety of enclosures, whether in sealed or ported configurations, allowing users to customize their bass experience for different auditory preferences and vehicle types. Additionally, the stellar sensitivity ratings enable these subwoofers to produce powerful sound even with lower amplification, making them a great choice for those looking to maximize sound output without the need for extreme power setups.

In summary, Orion’s HCCA series, featuring models like the HCCA 12.04, HCCA 10.2, HCCA 15.4, HCCA 12.2, and HCCA 10.4, stands out for its exceptional power handling, advanced technologies, durable construction, and versatility in installation. They cater to car audio enthusiasts who demand the best in bass performance, making them a premier choice in the realm of car audio subwoofers.