5.0 OPERATION

Once the Model 1075 is properly configured and installed, it should operate

5.1 LED STATUS MONITORS

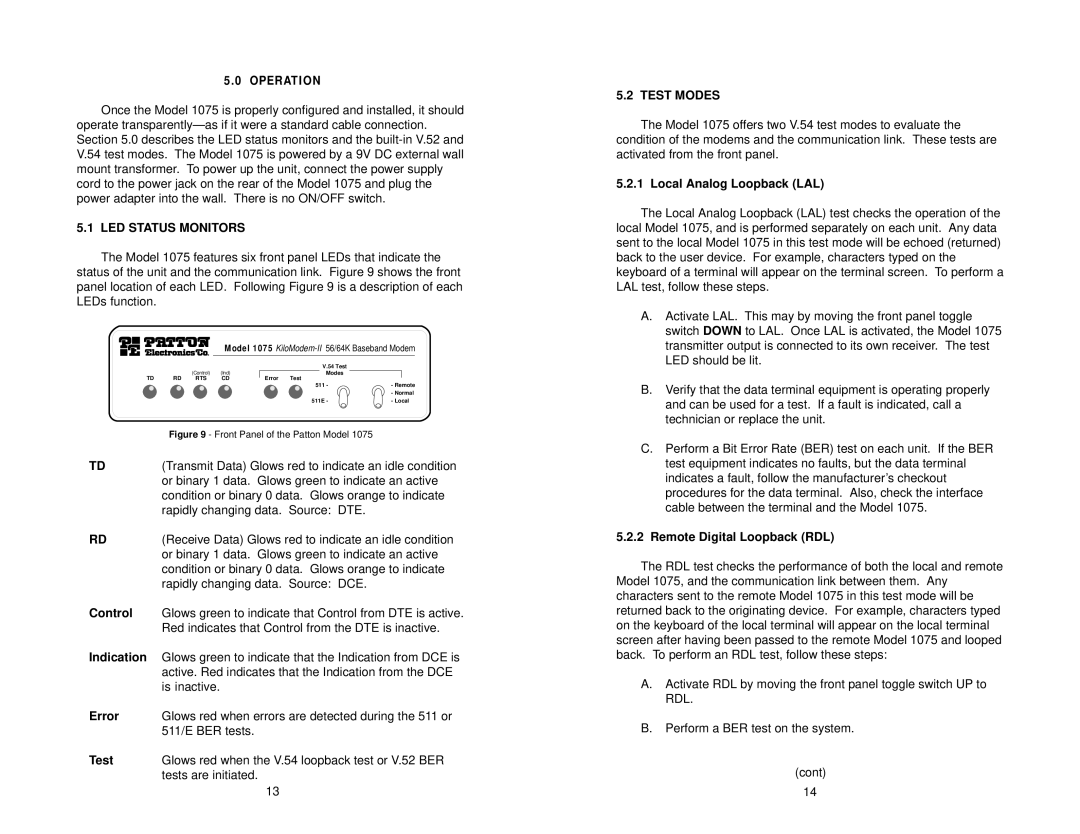

The Model 1075 features six front panel LEDs that indicate the status of the unit and the communication link. Figure 9 shows the front panel location of each LED. Following Figure 9 is a description of each LEDs function.

Model 1075

|

|

|

|

| V.54 Test |

| |

|

| (Control) | (Ind) |

|

| Modes |

|

TD | RD | RTS | CD | Error | Test |

|

|

|

|

|

|

| 511 | - | - Remote |

|

|

|

|

|

|

| - Normal |

|

|

|

|

| 511E | - | - Local |

| Figure 9 - Front Panel of the Patton Model 1075 |

TD | (Transmit Data) Glows red to indicate an idle condition |

| or binary 1 data. Glows green to indicate an active |

| condition or binary 0 data. Glows orange to indicate |

| rapidly changing data. Source: DTE. |

RD | (Receive Data) Glows red to indicate an idle condition |

| or binary 1 data. Glows green to indicate an active |

| condition or binary 0 data. Glows orange to indicate |

| rapidly changing data. Source: DCE. |

Control | Glows green to indicate that Control from DTE is active. |

| Red indicates that Control from the DTE is inactive. |

Indication | Glows green to indicate that the Indication from DCE is |

| active. Red indicates that the Indication from the DCE |

| is inactive. |

Error | Glows red when errors are detected during the 511 or |

| 511/E BER tests. |

Test | Glows red when the V.54 loopback test or V.52 BER |

| tests are initiated. |

| 13 |

5.2 TEST MODES

The Model 1075 offers two V.54 test modes to evaluate the condition of the modems and the communication link. These tests are activated from the front panel.

5.2.1 Local Analog Loopback (LAL)

The Local Analog Loopback (LAL) test checks the operation of the local Model 1075, and is performed separately on each unit. Any data sent to the local Model 1075 in this test mode will be echoed (returned) back to the user device. For example, characters typed on the keyboard of a terminal will appear on the terminal screen. To perform a LAL test, follow these steps.

A.Activate LAL. This may by moving the front panel toggle switch DOWN to LAL. Once LAL is activated, the Model 1075 transmitter output is connected to its own receiver. The test LED should be lit.

B.Verify that the data terminal equipment is operating properly and can be used for a test. If a fault is indicated, call a technician or replace the unit.

C.Perform a Bit Error Rate (BER) test on each unit. If the BER test equipment indicates no faults, but the data terminal indicates a fault, follow the manufacturer’s checkout procedures for the data terminal. Also, check the interface cable between the terminal and the Model 1075.

5.2.2Remote Digital Loopback (RDL)

The RDL test checks the performance of both the local and remote Model 1075, and the communication link between them. Any characters sent to the remote Model 1075 in this test mode will be returned back to the originating device. For example, characters typed on the keyboard of the local terminal will appear on the local terminal screen after having been passed to the remote Model 1075 and looped back. To perform an RDL test, follow these steps:

A.Activate RDL by moving the front panel toggle switch UP to RDL.

B.Perform a BER test on the system.

(cont)

14