The 1508he is best used as the bottom end of a full range enclosure. It has very high efficiency for superior output in the

The 1208sps works well in sealed or vented enclosure designs, and its smooth, extended frequency response makes it an excellent

Because the 1208sps’s low frequency output is limited, it should be used along with a subwoofer when response below 60 Hz is needed. The best application for the 1208sps is in compact enclosures and very high quality

The 15" drivers can work with crossover points as high as 2.0 kHz but work best below 1.5 kHz. The 12" drivers are usable to 3.5 kHz but perform best below 2.5 kHz.

ENCLOSURES

To assist with the growing interest in

Vents used in the examples require standard Schedule 40 PVC pipe for vent construction. The pipe should be dadoed tightly into the back of the baffle and glued firmly in place with high quality epoxy or high strength industrial grade hot glue. Rough up the outside of the pipe to improve the glue bond.

Be sure to account for the displacement of the vent, bracing, horn (if used) and woofer or your enclosure before building it, or it will be smaller than its intended volume. This can reduce bass output and

Line the inside of the enclosure with polyester fiber batting such as quilt stuffing. The batting material should conform to California bedding fire codes. Attach the batting with spray adhesive or staples, and keep it away from the end of the vent tube where it could be pulled in by air flow. Handles, protective corners, cabinet covering, grille materials and crossovers are available through Peavey Accessories.

When building a bandpass enclosure, design a panel or door to be removable for access to the woofer. Use foam

enclosure together for optimum performance in any application.

PARAMETER DEFINITIONS

Znom: The nominal impedance of the driver in Ohms.

Revc: DC resistance of the driver in Ohms. Also known as Re.

Sd: The functional radiating surface area of the cone assembly, in meters2.

BL: Efficiency of the voice coil and magnet system in Telsa Meters.

Fo: Also known as Fs, the free air resonance of the driver.

Vas: Volume of air having the same

compliance (springiness) as the driver’s suspension.

Cms: Restorative force of the driver’s suspension in micrometers/Newton.

Mms: The total mass of the moving

parts of the loudspeaker, including the air load, in grams.

Qms: Resonance characteristics of the mechanical factors of the loudspeaker.

Qes: Resonance characteristics of electrical factors of the loudspeaker.

SPECIFICATIONS

Model Name: | ||||||

Part #: | 00452850 | 00452860 | 00452870 | 00457680 | 00452830 | 00452840 |

Size: inches/mm | 15" / 380 mm | 15" / 380 mm | 15" / 380 mm | 15" / 380 mm | 12" / 305 mm | 12" / 305 mm |

| nominal | nominal | nominal | nominal | nominal | nominal |

| Frame OD 15- | Frame OD 15- | Frame OD 15- | Frame OD 15- | Frame OD 12- | Frame OD 12- |

| 1/4" / 387 mm | 1/4" / 387 mm | 1/4" / 387 mm | 1/4" / 387 mm | 1/4" / 311 mm | 1/4" / 311 mm |

| Bolt circle | Bolt circle | Bolt circle | Bolt circle | Bolt circle | Bolt circle |

| 11- 5/8" | 11- 5/8" | ||||

| 370 mm, 8 holes | 370mm,8holes | 370 mm, 8 holes | 370 mm, 8 holes | 295 mm, 8 holes | 295 mm, 8 holes |

| Cutout diameter | Cutout diameter | Cutout diameter | Cutout diameter | Cutout diameter | Cutout diameter |

| 14" / 356 mm | 14" / 356 mm | 14" / 356 mm | 14" / 356 mm | 10 15/16" / 278 mm | 10 15/16" / 278 mm |

| Depth | Depth | Depth | Depth | Depth | Depth |

| 126 mm | 126 mm | 126 mm | 126 mm | 90 mm | 90mm |

Impedance: | 8 Ohms | 4 Ohms | 8 Ohms | 8 Ohms | 8 Ohms | 4 Ohms |

Power Capacity: | 2000 W peak | 2000 W peak | 2000 W peak | 2000 W peak | 2000 W peak | 2000 W peak |

| 1000 W program 1000 W program | 1000 W program | 1000 W program | 1000 W program | 1000 W program | |

| 500 W continuous | 500 W continuous | 500 W continuous | 500 W continuous | 500 W continuous | 500 W continuous |

| per AES | per AES | per AES | per AES | per AES | per AES |

| 50 Hz - 500 Hz | 50 Hz - 500 Hz | 50 Hz - 500 Hz | 50 Hz - 500 Hz | 65 Hz - 650 Hz | 65 Hz - 650 Hz |

Sensitivity: | 96.7 dB 1 Watt / | 97.5 dB 1 Watt / | 97.2 dB 1 Watt / | 100.3 dB 1 Watt / | 96.9 dB 1 watt / | 96.6 dB 1 watt / |

| 1 meter | 1 meter | 1 meter | 1 meter | 1 meter | 1 meter |

Usable |

|

|

|

|

|

|

frequency range: | 35 Hz ~ 2 kHz | 35 Hz ~ 2 kHz | 35 Hz ~ 2 kHz | 40 Hz ~ 2 kHz | 50 Hz ~ 3.5 kHz | 50 Hz ~ 3.5 kHz |

Cone: | Kevlar® | Kevlar | Kevlar | Kevlar | Kevlar | Kevlar |

| impregnated | impregnated | impregnated | impregnated | impregnated | impregnated |

| cellulose | cellulose | cellulose | cellulose | cellulose | cellulose |

Voice coil diam: | 4.0" / 100 mm | 4.0" / 100 mm | 4.0" / 100 mm | 4.0" / 100 mm | 4.0" / 100 mm | 4.0" / 100 mm |

Voice coil material: | Aluminum ribbon | Aluminum ribbon | Copper ribbon | Aluminum ribbon | Aluminum ribbon | Aluminum ribbon |

| wire | wire | wire | wire | wire | wire |

| Polyimide- | Polyimide- | Polyimide- | Polyimide- | Polyimide- | Polyimide- |

| impregnated | impregnated | impregnated | impregnated | impregnated | impregnated |

| fiberglass | fiberglass | fiberglass | fiberglass | fiberglass | fiberglass |

| former | former | former | former | former | former |

| Nomex® stiffener Nomex stiffener | Nomex stiffener | Nomex stiffener | Nomex stiffener | Nomex stiffener | |

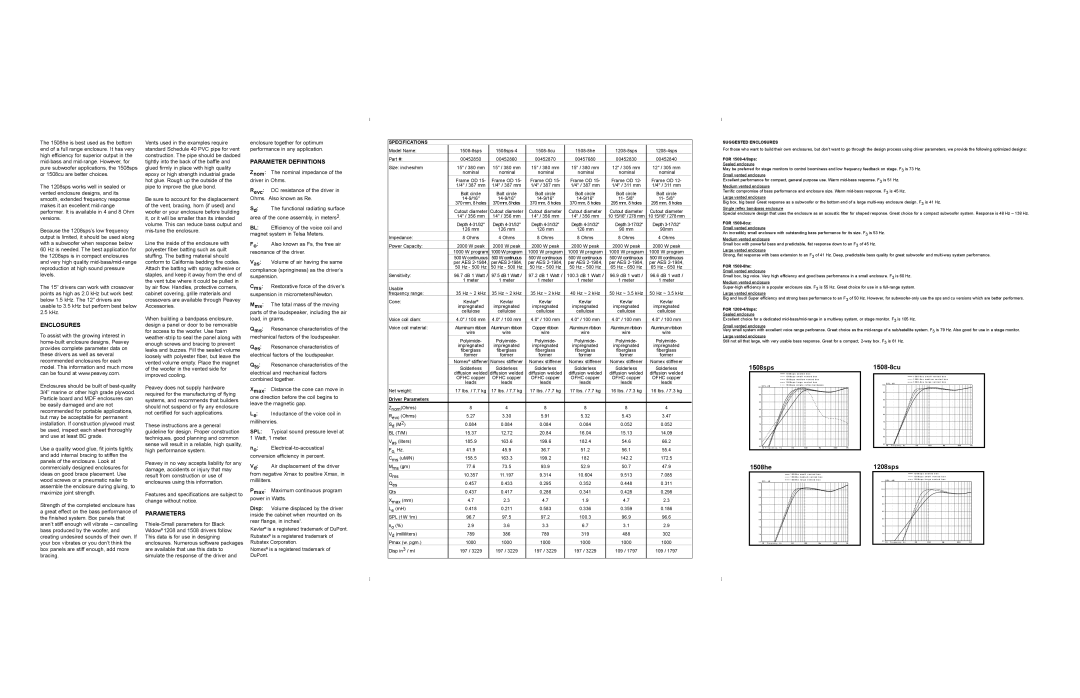

SUGGESTED ENCLOSURES

For those who want to build their own enclosures, but don’t want to go through the design process using driver parameters, we provide the following optimized designs:

FOR 1508-4/8sps:

Sealed enclosure

May be preferred for stage monitors to control boominess and low frequency feedback on stage. F3 is 73 Hz.

Small vented enclosure

Excellent performance for compact, general purpose use. Warm

Medium vented enclosure

Terrific compromise of bass performance and enclosure size. Warm

Large vented enclosure

Big box, big bass! Great response as a subwoofer or the bottom end of a large

Single reflex bandpass enclosure

Special enclosure design that uses the enclosure as an acoustic filter for shaped response. Great choice for a compact subwoofer system. Response is 48 Hz – 138 Hz.

FOR 1508-8cu:

Small vented enclosure

An incredibly small enclosure with outstanding bass performance for its size. F3 is 53 Hz.

Medium vented enclosure

Small box with powerful bass and predictable, flat response down to an F3 of 45 Hz.

Large vented enclosure

Strong, flat response with bass extension to an F3 of 41 Hz. Deep, predictable bass quality for great subwoofer and

FOR 1508-8he:

Small vented enclosure

Small box, big voice. Very high efficiency and good bass performance in a small enclosure. F3 is 60 Hz.

Medium vented enclosure

Large vented enclosure

Big and loud! Super efficiency and strong bass performance to an F3 of 50 Hz. However, for

FOR 1208-4/8sps:

Sealed enclosure

Excellent choice for a dedicated

Small vented enclosure

Very small system with excellent voice range perforance. Great choice as the

Large vented enclosure

Still not all that large, with very usable bass response. Great for a compact,

model. This information and much more can be found at www.peavey.com.

Enclosures should be built of

Use a quality wood glue, fit joints tightly, and add internal bracing to stiffen the panels of the enclosure. Look at commercially designed enclosures for ideas on good brace placement. Use wood screws or a pneumatic nailer to assemble the enclosure during gluing, to maximize joint strength.

Strength of the completed enclosure has a great effect on the bass performance of the finished system. Box panels that aren’t stiff enough will vibrate – cancelling bass produced by the woofer, and creating undesired sounds of their own. If your box vibrates or you don’t think the box panels are stiff enough, add more bracing.

vented volume empty. Place the magnet of the woofer in the vented side for improved cooling.

Peavey does not supply hardware required for the manufacturing of flying systems, and recommends that builders should not suspend or fly any enclosure not certified for such applications.

These instructions are a general guideline for design. Proper construction techniques, good planning and common sense will result in a reliable, high quality, high performance system.

Peavey in no way accepts liability for any damage, accidents or injury that may result from construction or use of enclosures using this information.

Features and specifications are subject to change without notice.

PARAMETERS

Qts: Resonance characteristics of the

electrical and mechanical factors combined together.

Xmax: Distance the cone can move in

one direction before the coil begins to leave the magnetic gap.

Le: Inductance of the voice coil in millihenries.

SPL: Typical sound pressure level at 1 Watt, 1 meter.

no:

Vd: Air displacement of the driver

from negative Xmax to positive Xmax, in milliliters.

Pmax: Maximum continuous program power in Watts.

Disp: Volume displaced by the driver inside the cabinet when mounted on its rear flange, in inches3.

Kevlar® is a registered trademark of DuPont.

Rubatex® is a registered trademark of Rubatex Corporation.

Nomex® is a registered trademark of DuPont.

| Solderless | Solderless | Solderless | Solderless | Solderless | Solderless |

| diffusion welded | diffusion welded | diffusion welded | diffusion welded | diffusion welded | diffusion welded |

| OFHC copper | OFHC copper | OFHC copper | OFHC copper | OFHC copper | OFHC copper |

| leads | leads | leads | leads | leads | leads |

Net weight: | 17 lbs. / 7.7 kg | 17 lbs. / 7.7 kg | 17 lbs. / 7.7 kg | 17 lbs. / 7.7 kg | 16 lbs. / 7.3 kg | 16 lbs. / 7.3 kg |

Driver Parameters |

|

|

|

|

|

|

Znom(Ohms) | 8 | 4 | 8 | 8 | 8 | 4 |

Revc (Ohms) | 5.27 | 3.30 | 5.91 | 5.32 | 5.43 | 3.47 |

Sd (M2) | 0.084 | 0.084 | 0.084 | 0.084 | 0.052 | 0.052 |

BL (T/M) | 15.37 | 12.72 | 20.84 | 16.04 | 15.13 | 14.09 |

Vas (liters) | 185.9 | 163.6 | 199.6 | 182.4 | 54.6 | 66.2 |

Fo, Hz. | 41.9 | 45.9 | 36.7 | 51.2 | 56.1 | 55.4 |

Cms (uM/N) | 158.5 | 163.3 | 199.2 | 182 | 142.2 | 172.5 |

Mms (gm) | 77.6 | 73.5 | 93.9 | 52.9 | 50.7 | 47.9 |

Qms | 10.357 | 11.197 | 9.314 | 10.604 | 9.513 | 7.085 |

Qes | 0.457 | 0.433 | 0.295 | 0.352 | 0.448 | 0.311 |

Qts | 0.437 | 0.417 | 0.286 | 0.341 | 0.428 | 0.298 |

Xmax (mm) | 4.7 | 2.3 | 4.7 | 1.9 | 4.7 | 2.3 |

Le (mH) | 0.418 | 0.211 | 0.583 | 0.336 | 0.359 | 0.186 |

SPL (1W 1m) | 96.7 | 97.5 | 97.2 | 100.3 | 96.9 | 96.6 |

no (%) | 2.9 | 3.6 | 3.3 | 6.7 | 3.1 | 2.9 |

Vd (milliliters) | 789 | 386 | 789 | 319 | 488 | 302 |

Pmax (w. pgm.) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

Disp in3 / ml | 197 / 3229 | 197 / 3229 | 197 / 3229 | 197 / 3229 | 109 / 1797 | 109 / 1797 |

1508sps |

|

|

|

|

|

| 1 5 0 8 s p s s e a l e d b o x |

|

|

| |

| 1 5 0 8 s p s s m a l l v e n t e d b o x |

|

|

| |

| 1 5 0 8 s p s m e d i u m v e n t e d b o x |

|

| ||

| 1 5 0 8 s p s l a r g e v e n t e d b o x |

|

|

| |

S P L , d B | 1 5 0 8 s p s s i n g l e r e f l e x b a n d p a s s |

|

| ||

1 0 0 |

|

|

|

|

|

9 5 |

|

|

|

|

|

9 0 |

|

|

|

|

|

8 5 |

|

|

|

|

|

8 0 |

|

|

|

|

|

7 5 |

|

|

|

|

|

7 0 |

|

|

|

|

|

6 5 |

|

|

|

|

|

6 0 | 5 0 | 1 0 0 | Hz | 5 0 0 | 1 K |

1 0 F r e q u e n c y , H z | |||||

1508he |

|

|

|

|

| |

|

| 1 5 0 8 h e s m a l l v e n t e d b o x |

|

| ||

|

| 1 5 0 8 h e m e d i u m v e n t e d b o x |

|

| ||

S P L , | d B | 1 5 0 8 h e l a r g e v e n t e d b o x |

|

| ||

|

|

|

|

| ||

1 0 5 |

|

|

|

|

|

|

1 0 0 |

|

|

|

|

|

|

9 5 |

|

|

|

|

|

|

9 0 |

|

|

|

|

|

|

8 5 |

|

|

|

|

|

|

8 0 |

|

|

|

|

|

|

7 5 |

|

|

|

|

|

|

7 0 |

|

|

|

|

|

|

6 5 | F r e q u e n c y , H z | 5 0 | 1 0 0 | Hz | 5 0 0 | 1 K |

1 0 | ||||||

|

|

|

|

|

| |

|

| 1 5 0 8 - 8 c u s m a l l v e n t e d b o x |

|

| ||

|

| 1 5 0 8 - 8 c u m e d i u m v e n t e d b o x |

|

| ||

S P L , | d B | 1 5 0 8 - 8 c u l a r g e v e n t e d b o x |

|

| ||

|

|

|

|

| ||

1 0 0 |

|

|

|

|

|

|

9 5 |

|

|

|

|

|

|

9 0 |

|

|

|

|

|

|

8 5 |

|

|

|

|

|

|

8 0 |

|

|

|

|

|

|

7 5 |

|

|

|

|

|

|

7 0 |

|

|

|

|

|

|

6 5 |

|

|

|

|

|

|

6 0 | F r e q u e n c y , H z | 5 0 | 1 0 0 | Hz | 5 0 0 | 1 K |

1 0 | ||||||

1208sps |

|

|

|

|

| |

|

| 1 2 0 8 s p s s e a l e d b o x |

|

|

| |

|

| 1 2 0 8 s p s s m a l l v e n t e d b o x |

|

| ||

S P L , d B | 1 2 0 8 s p s l a r g e v e n t e d b o x |

|

| |||

1 0 5 |

|

|

|

|

|

|

1 0 0 |

|

|

|

|

|

|

9 5 |

|

|

|

|

|

|

9 0 |

|

|

|

|

|

|

8 5 |

|

|

|

|

|

|

8 0 |

|

|

|

|

|

|

7 5 |

|

|

|

|

|

|

7 0 |

|

|

|

|

|

|

6 5 | F r e q u e n c y , H z | 5 0 | 1 0 0 | Hz | 5 0 0 | 1 K |

1 0 | ||||||