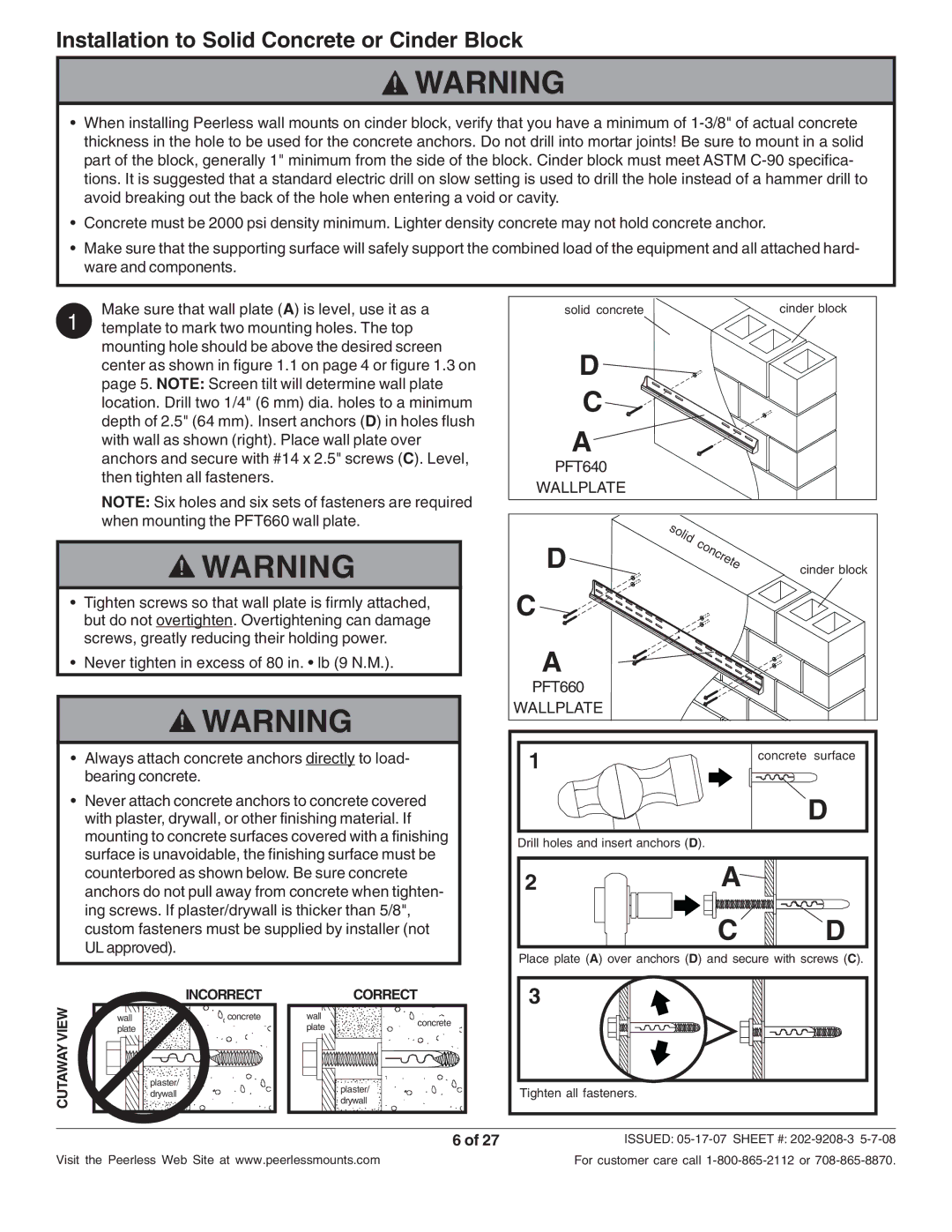

PFT640, PFT660 specifications

Peerless Industries has established itself as a prominent provider of mounting solutions, particularly revered for its innovative products tailored to enhance the display experience in various settings. Among their noteworthy offerings are the Peerless PFT660 and PFT640, two versatile mounting solutions designed to meet the dynamic needs of commercial spaces, classrooms, and home entertainment environments.The Peerless PFT660 is a full-featured floor stand that accommodates larger displays, making it ideal for modern conference rooms and public presentations. One of its standout features is its sleek, contemporary design that seamlessly integrates into any décor. The PFT660 supports a wide range of display sizes, from 50 to 80 inches, and has a robust weight capacity, ensuring stability and reliability even for heavier screens. Its adjustable height feature provides flexibility for various viewing preferences, allowing users to customize the screen's position for optimal visibility.

In contrast, the Peerless PFT640 offers a more compact solution suitable for medium-sized displays of 32 to 55 inches. This model is designed with portability in mind, making it easy to relocate as needed. The lightweight construction of the PFT640 does not compromise durability, as it is built from high-quality materials that ensure long-lasting performance. Similar to the PFT660, the PFT640 features a sleek and modern design, but with a smaller footprint that makes it perfect for smaller venues or spaces.

Both mounts leverage advanced engineering technologies to facilitate quick installation and easy setup. The cable management system integrated into both models allows for a clean and organized appearance, reducing clutter and improving aesthetics. Furthermore, both the PFT660 and PFT640 are designed to accommodate various media devices, including streaming players and laptops, catering to the needs of diverse users.

In summary, the Peerless PFT660 and PFT640 are exemplary mounting solutions that embody functionality, style, and versatility. With their user-friendly features, sturdy construction, and adaptability to a range of display sizes and environments, both models contribute significantly to the enhancement of visual engagement in any setting, ensuring that they meet the demands of today's technology-driven world effectively.