812W0100 specifications

The Pella 812W0100 is a high-performance window that embodies innovative engineering and advanced technology, ensuring it meets the diverse needs of modern homeowners. Designed for both aesthetics and functionality, this product stands out as a premier choice for new constructions and renovations alike.One of the primary features of the Pella 812W0100 is its energy efficiency. This window is equipped with advanced Low-E glass that reflects heat in the summer and retains warmth in the winter. This technology significantly enhances thermal insulation, helping to reduce heating and cooling costs throughout the year. The Pella 812W0100 also comes with multiple glazing options, allowing homeowners to customize their window’s energy performance according to their climate and specific needs.

In terms of durability, the Pella 812W0100 boasts a robust frame made from high-quality materials that resist warping, cracking, and fading. The window is constructed with a unique fiberglass and composite blend that provides long-lasting strength and stability, making it an excellent choice for areas with extreme weather conditions. Additionally, the window's exterior is designed to withstand harsh elements without compromising its appearance.

The design of the Pella 812W0100 offers versatility that caters to various architectural styles. Available in multiple colors and finishes, homeowners can choose options that seamlessly blend with their home’s exterior and interior decor. The window's sleek lines and large viewing area maximize natural light while providing unobstructed views of the outdoors.

For added convenience, the Pella 812W0100 features an easy-to-use locking system that enhances security without sacrificing style. The window operates smoothly, thanks to its precision-engineered hardware, ensuring long-term reliability.

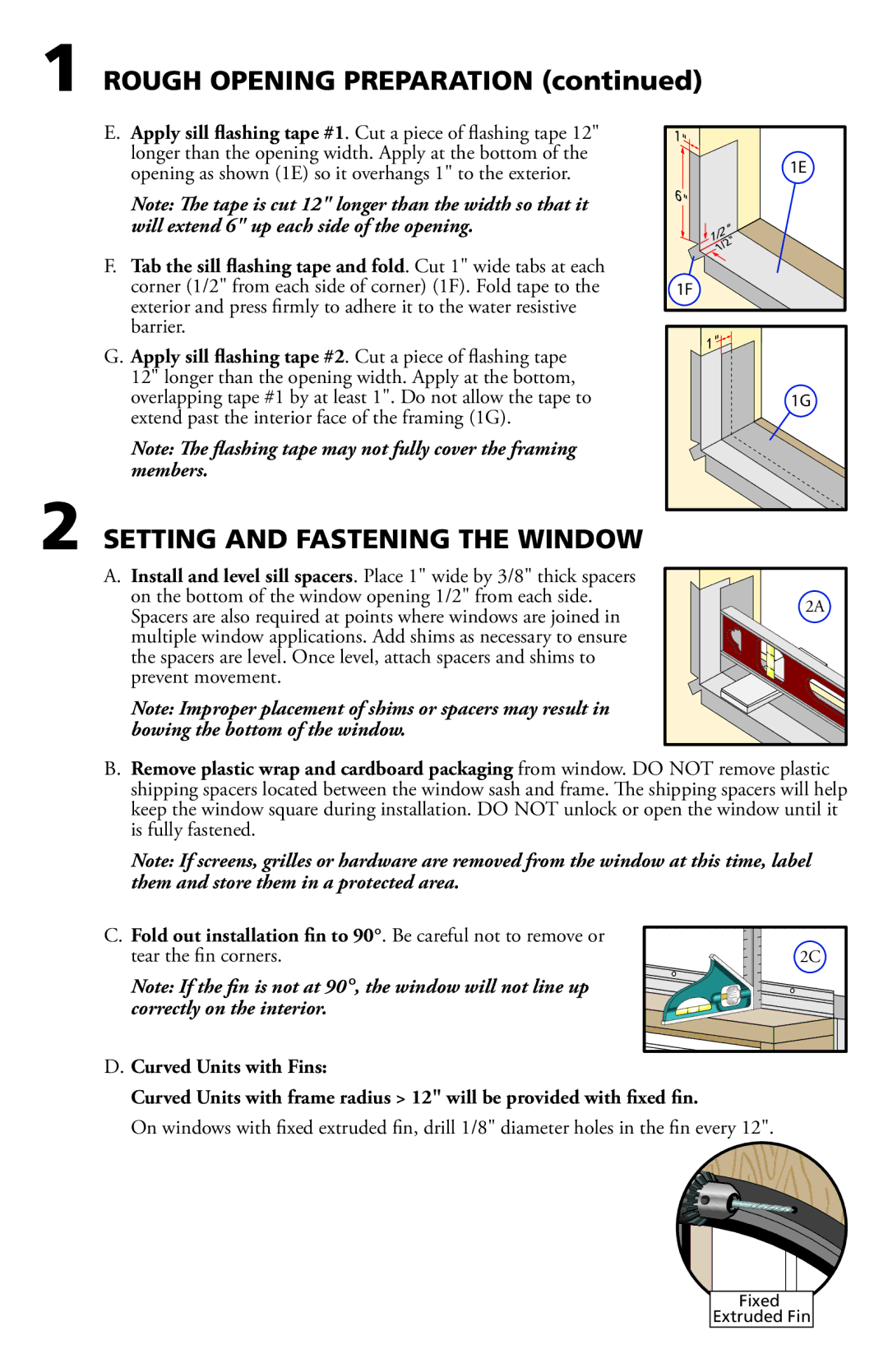

Installation and maintenance of the Pella 812W0100 are also streamlined. This window is designed for easy installation, reducing labor costs and time spent during the building process. Furthermore, its low-maintenance exterior simply requires periodic cleaning to keep it looking fresh and new.

Ultimately, the Pella 812W0100 combines cutting-edge technology, energy efficiency, aesthetic appeal, and robust durability, making it an ideal choice for homeowners looking to enhance their living spaces while optimizing energy savings and security.