899713 -

GOOD SANDING TECHNIQUE

Getting the feel of your sander is most important in obtaining smooth results with a minimum of labor. You will quickly learn how to start the stroke with a sweeping motion that wil produce the best results. Use a long even stroke without any additional pressure on the machine. Overlap each stroke and vary the length of movement so the results will be even over the entire surface. Always lift the sander from the work before starting and stopping the motor.

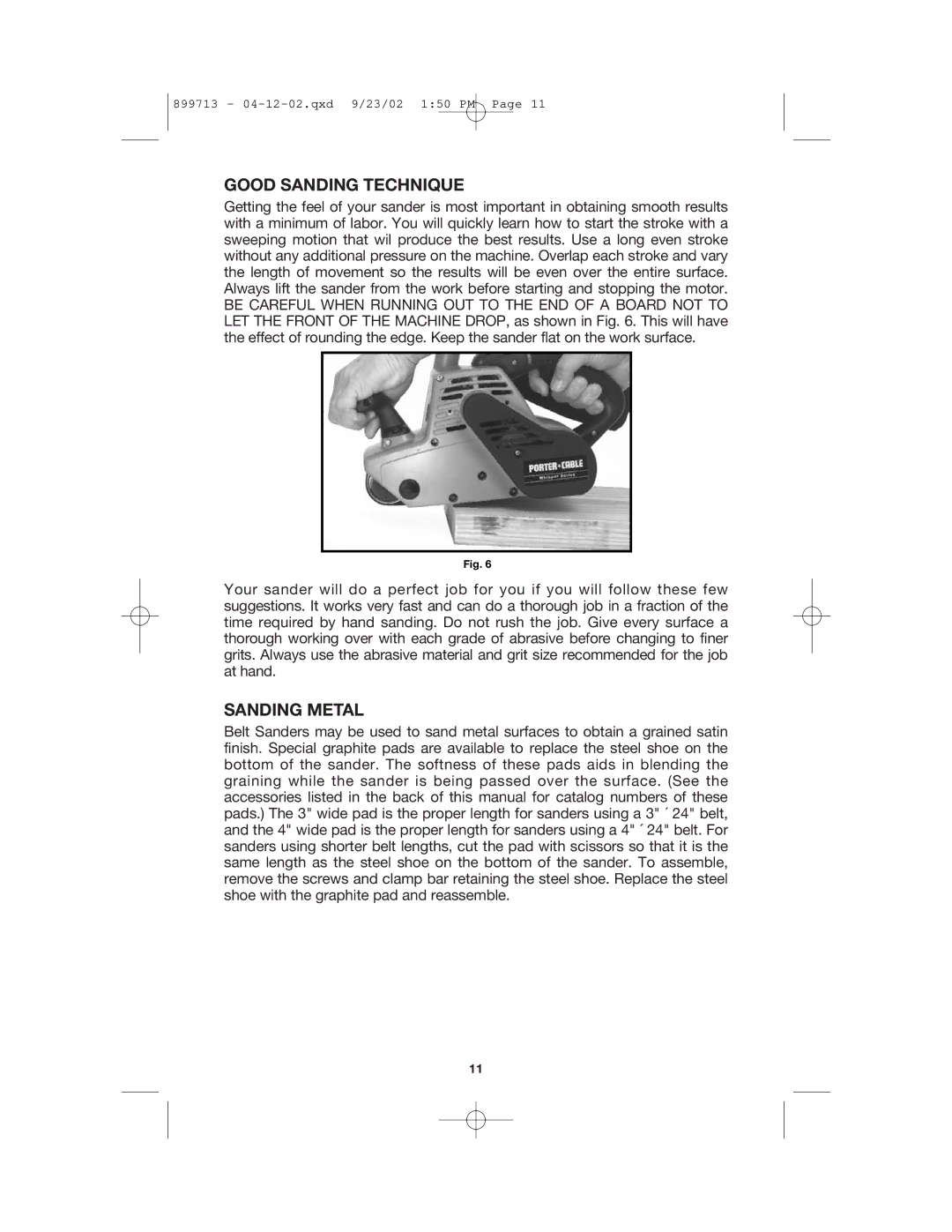

BE CAREFUL WHEN RUNNING OUT TO THE END OF A BOARD NOT TO LET THE FRONT OF THE MACHINE DROP, as shown in Fig. 6. This will have the effect of rounding the edge. Keep the sander flat on the work surface.

Fig. 6

Your sander will do a perfect job for you if you will follow these few suggestions. It works very fast and can do a thorough job in a fraction of the time required by hand sanding. Do not rush the job. Give every surface a thorough working over with each grade of abrasive before changing to finer grits. Always use the abrasive material and grit size recommended for the job at hand.

SANDING METAL

Belt Sanders may be used to sand metal surfaces to obtain a grained satin finish. Special graphite pads are available to replace the steel shoe on the bottom of the sander. The softness of these pads aids in blending the graining while the sander is being passed over the surface. (See the accessories listed in the back of this manual for catalog numbers of these pads.) The 3" wide pad is the proper length for sanders using a 3" ´ 24" belt, and the 4" wide pad is the proper length for sanders using a 4" ´ 24" belt. For sanders using shorter belt lengths, cut the pad with scissors so that it is the same length as the steel shoe on the bottom of the sander. To assemble, remove the screws and clamp bar retaining the steel shoe. Replace the steel shoe with the graphite pad and reassemble.

11