MAINTENANCE

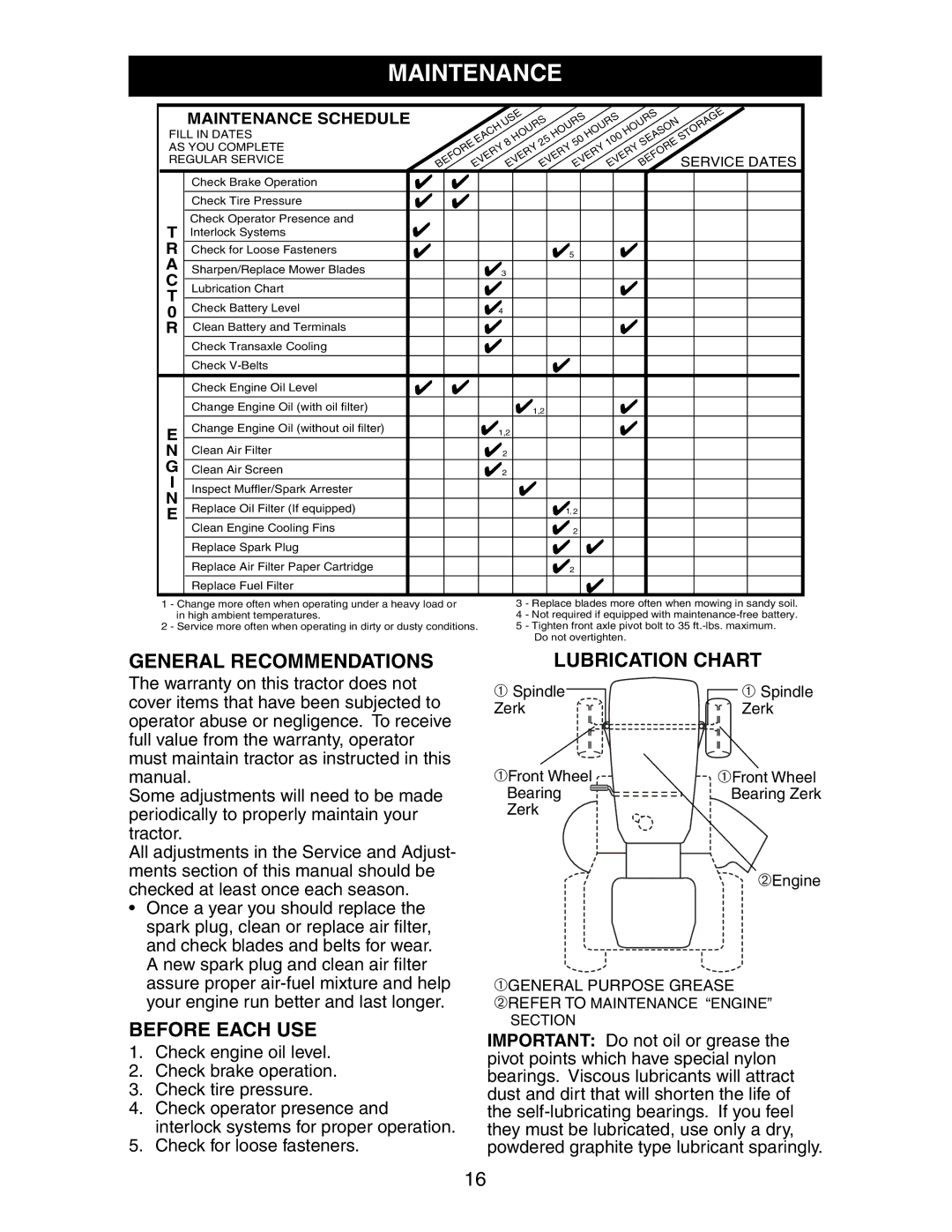

MAINTENANCE SCHEDULE

FILL IN DATES

AS YOU COMPLETE

REGULAR SERVICE

Check Brake Operation

Check Tire Pressure

Check Operator Presence and

TInterlock Systems

R Check for Loose Fasteners

ASharpen/Replace Mower Blades

C | Lubrication Chart |

T |

0Check Battery Level

RClean Battery and Terminals Check Transaxle Cooling Check

Check Engine Oil Level

Change Engine Oil (with oil filter)

EChange Engine Oil (without oil filter)

NClean Air Filter

GClean Air Screen

I | Inspect Muffler/Spark Arrester |

N |

EReplace Oil Filter (If equipped) Clean Engine Cooling Fins

Replace Spark Plug

Replace Air Filter Paper Cartridge Replace Fuel Filter

| E |

|

|

| HOURS |

|

|

| STORAGE | ||

|

|

|

|

| E |

|

|

| HOURS |

|

|

| AC |

| S |

| HOURSHOURS |

|

|

| |||

E |

| U |

| 25 | 50 | 100 | SEASON |

| |||

H |

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

| ||

BEFO |

|

|

| 8 |

|

|

|

|

| SERVICE DATES | |

EVERY EVERY EVERY EVERY EVERYBEFORE | |||||||||||

R |

|

|

|

|

|

|

|

|

|

|

|

![]() 5

5

![]() 3

3

4

![]() 1,2

1,2

![]() 1,2

1,2

![]() 2

2

![]() 2

2

1, 2

![]() 2

2

![]() 2

2

1 - Change more often when operating under a heavy load or in high ambient temperatures.

2 - Service more often when operating in dirty or dusty conditions.

3 - Replace blades more often when mowing in sandy soil. 4 - Not required if equipped with

Do not overtighten.

GENERAL RECOMMENDATIONS

LUBRICATION CHART

The warranty on this tractor does not cover items that have been subjected to operator abuse or negligence. To receive full value from the warranty, operator must maintain tractor as instructed in this manual.

Some adjustments will need to be made periodically to properly maintain your tractor.

All adjustments in the Service and Adjust- ments section of this manual should be checked at least once each season.

➀Spindle Zerk

➀Front Wheel

Bearing

Zerk

➀Spindle Zerk

➀Front Wheel Bearing Zerk

➁Engine

•Once a year you should replace the spark plug, clean or replace air filter, and check blades and belts for wear. A new spark plug and clean air filter assure proper

BEFORE EACH USE

1.Check engine oil level.

2.Check brake operation.

3.Check tire pressure.

4.Check operator presence and interlock systems for proper operation.

5.Check for loose fasteners.

➀GENERAL PURPOSE GREASE

➁REFER TO MAINTENANCE “ENGINE” SECTION

IMPORTANT: Do not oil or grease the pivot points which have special nylon bearings. Viscous lubricants will attract dust and dirt that will shorten the life of the

16