ASSEMBLY

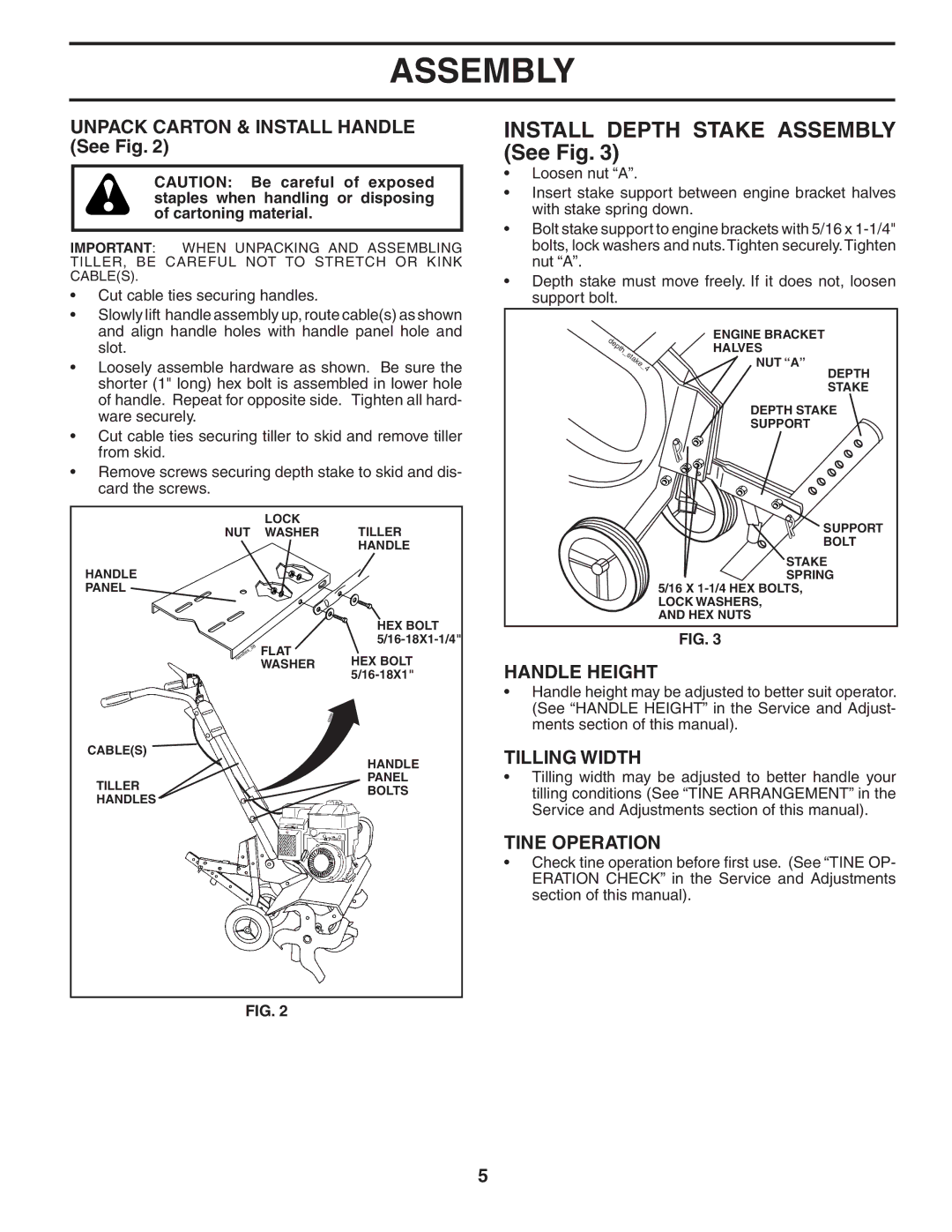

UNPACK CARTON & INSTALL HANDLE (See Fig. 2)

CAUTION: Be careful of exposed staples when handling or disposing of cartoning material.

IMPORTANT: WHEN UNPACKING AND ASSEMBLING TILLER, BE CAREFUL NOT TO STRETCH OR KINK CABLE(S).

•Cut cable ties securing handles.

•Slowly lift handle assembly up, route cable(s) as shown and align handle holes with handle panel hole and slot.

•Loosely assemble hardware as shown. Be sure the shorter (1" long) hex bolt is assembled in lower hole of handle. Repeat for opposite side. Tighten all hard- ware securely.

•Cut cable ties securing tiller to skid and remove tiller from skid.

•Remove screws securing depth stake to skid and dis- card the screws.

LOCK

NUT WASHER TILLER

HANDLE

HANDLE

PANEL

HEX BOLT

_38 | FLAT |

|

|

handles |

| HEX BOLT | |

WASHER |

| ||

|

| ||

|

|

| |

|

| 02 | 051 |

|

|

|

CABLE(S)

HANDLE

PANEL

TILLERBOLTS HANDLES

FIG. 2

INSTALL DEPTH STAKE ASSEMBLY (See Fig. 3)

•Loosen nut “A”.

•Insert stake support between engine bracket halves with stake spring down.

•Bolt stake support to engine brackets with 5/16 x

•Depth stake must move freely. If it does not, loosen support bolt.

depth_ | ENGINE BRACKET |

HALVES | |

stake_ | NUT “A” |

4 | DEPTH |

| |

| STAKE |

| DEPTH STAKE |

| SUPPORT |

SUPPORT

BOLT

STAKE

SPRING

5/16 X

FIG. 3

HANDLE HEIGHT

•Handle height may be adjusted to better suit operator. (See “HANDLE HEIGHT” in the Service and Adjust- ments section of this manual).

TILLING WIDTH

•Tilling width may be adjusted to better handle your tilling conditions (See “TINE ARRANGEMENT” in the Service and Adjustments section of this manual).

TINE OPERATION

•Check tine operation before first use. (See “TINE OP- ERATION CHECK” in the Service and Adjustments

section of this manual).

5