STARTING A COLD ENGINE

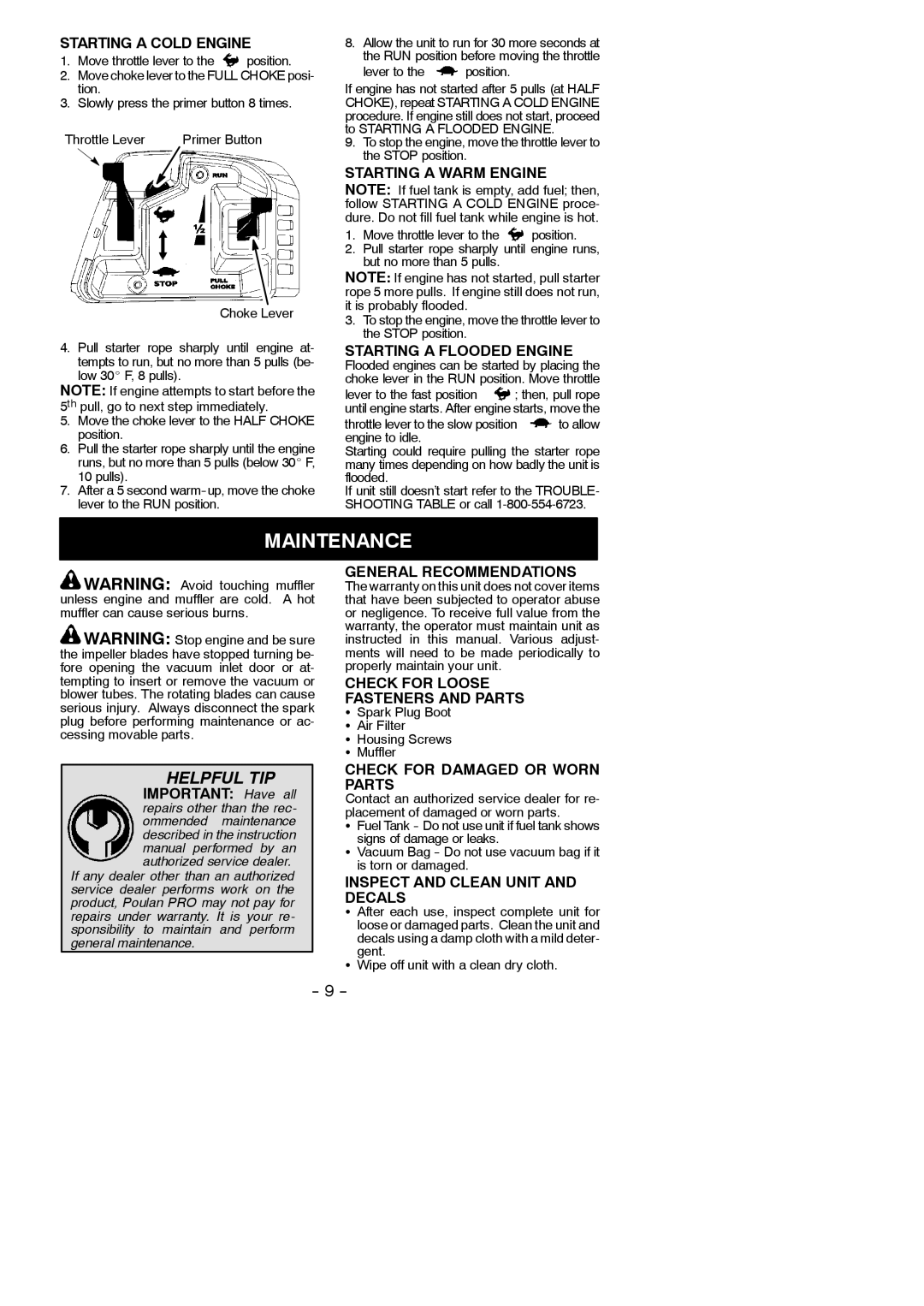

1.Move throttle lever to the ![]() position.

position.

2.Move choke lever to the FULL CHOKE posi- tion.

3.Slowly press the primer button 8 times.

Throttle Lever | Primer Button |

Choke Lever

4.Pull starter rope sharply until engine at- tempts to run, but no more than 5 pulls (be- low 30_ F, 8 pulls).

NOTE: If engine attempts to start before the 5th pull, go to next step immediately.

5.Move the choke lever to the HALF CHOKE position.

6.Pull the starter rope sharply until the engine runs, but no more than 5 pulls (below 30_ F, 10 pulls).

7.After a 5 second

8.Allow the unit to run for 30 more seconds at the RUN position before moving the throttle

lever to the  position.

position.

If engine has not started after 5 pulls (at HALF CHOKE), repeat STARTING A COLD ENGINE procedure. If engine still does not start, proceed to STARTING A FLOODED ENGINE.

9.To stop the engine, move the throttle lever to the STOP position.

STARTING A WARM ENGINE NOTE: If fuel tank is empty, add fuel; then, follow STARTING A COLD ENGINE proce- dure. Do not fill fuel tank while engine is hot.

1.Move throttle lever to the ![]() position.

position.

2.Pull starter rope sharply until engine runs, but no more than 5 pulls.

NOTE: If engine has not started, pull starter rope 5 more pulls. If engine still does not run, it is probably flooded.

3.To stop the engine, move the throttle lever to the STOP position.

STARTING A FLOODED ENGINE

Flooded engines can be started by placing the choke lever in the RUN position. Move throttle

lever to the fast position ![]() ; then, pull rope until engine starts. After engine starts, move the

; then, pull rope until engine starts. After engine starts, move the

throttle lever to the slow position | to allow |

engine to idle. |

|

Starting could require pulling the starter rope many times depending on how badly the unit is flooded.

If unit still doesn’t start refer to the TROUBLE- SHOOTING TABLE or call

MAINTENANCE

![]() WARNING: Avoid touching muffler unless engine and muffler are cold. A hot muffler can cause serious burns.

WARNING: Avoid touching muffler unless engine and muffler are cold. A hot muffler can cause serious burns.

![]() WARNING: Stop engine and be sure the impeller blades have stopped turning be- fore opening the vacuum inlet door or at- tempting to insert or remove the vacuum or blower tubes. The rotating blades can cause serious injury. Always disconnect the spark plug before performing maintenance or ac- cessing movable parts.

WARNING: Stop engine and be sure the impeller blades have stopped turning be- fore opening the vacuum inlet door or at- tempting to insert or remove the vacuum or blower tubes. The rotating blades can cause serious injury. Always disconnect the spark plug before performing maintenance or ac- cessing movable parts.

GENERAL RECOMMENDATIONS

The warranty on this unit does not cover items that have been subjected to operator abuse or negligence. To receive full value from the warranty, the operator must maintain unit as instructed in this manual. Various adjust- ments will need to be made periodically to properly maintain your unit.

CHECK FOR LOOSE

FASTENERS AND PARTS

SSpark Plug Boot S Air Filter

S Housing Screws S Muffler

HELPFUL TIP

IMPORTANT: Have all

repairs other than the rec- ommended maintenance described in the instruction manual performed by an authorized service dealer.

If any dealer other than an authorized service dealer performs work on the product, Poulan PRO may not pay for repairs under warranty. It is your re- sponsibility to maintain and perform general maintenance.

CHECK FOR DAMAGED OR WORN PARTS

Contact an authorized service dealer for re- placement of damaged or worn parts.

SFuel Tank

SVacuum Bag

INSPECT AND CLEAN UNIT AND DECALS

SAfter each use, inspect complete unit for loose or damaged parts. Clean the unit and decals using a damp cloth with a mild deter- gent.

SWipe off unit with a clean dry cloth.