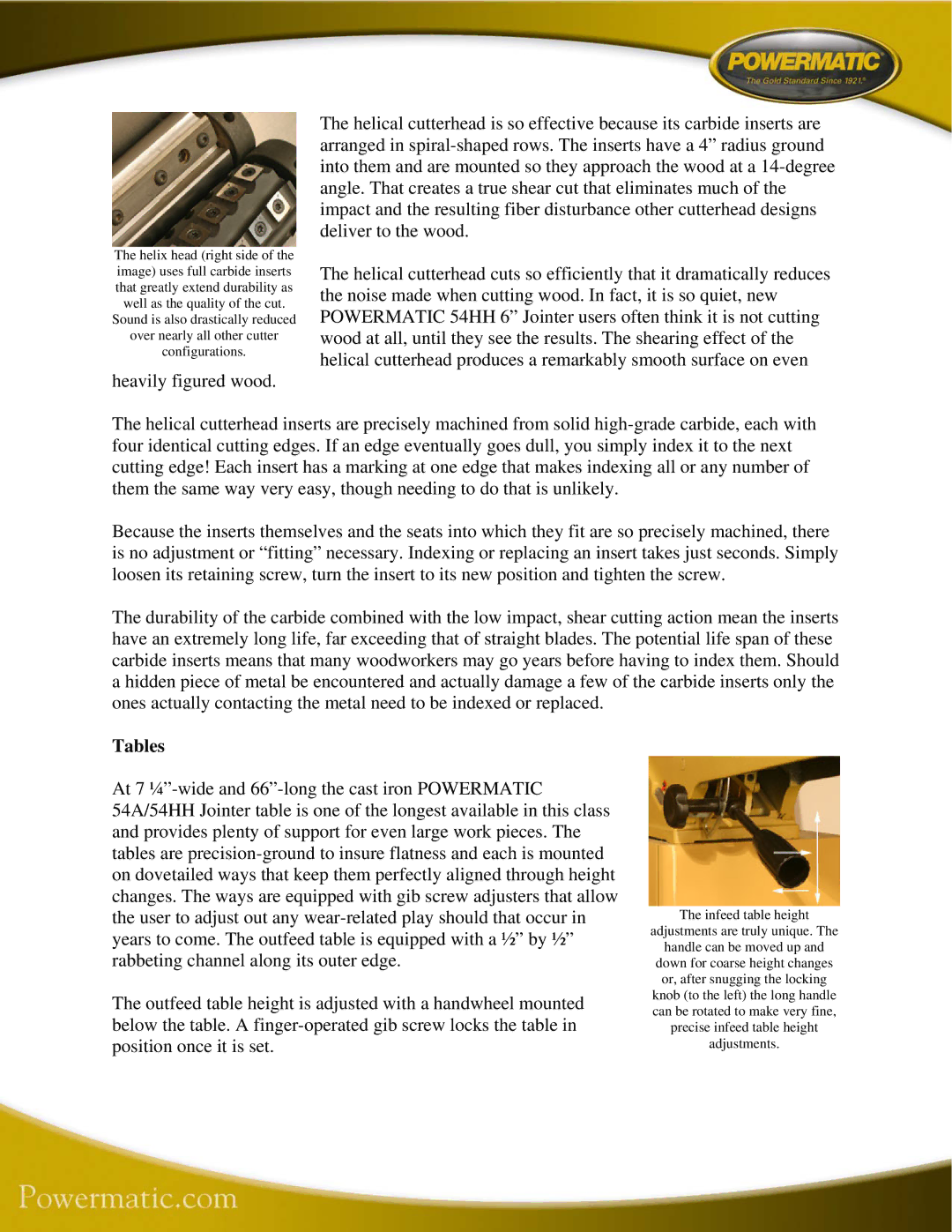

The helix head (right side of the image) uses full carbide inserts that greatly extend durability as well as the quality of the cut. Sound is also drastically reduced over nearly all other cutter configurations.

heavily figured wood.

The helical cutterhead is so effective because its carbide inserts are arranged in

The helical cutterhead cuts so efficiently that it dramatically reduces the noise made when cutting wood. In fact, it is so quiet, new POWERMATIC 54HH 6” Jointer users often think it is not cutting wood at all, until they see the results. The shearing effect of the helical cutterhead produces a remarkably smooth surface on even

The helical cutterhead inserts are precisely machined from solid

Because the inserts themselves and the seats into which they fit are so precisely machined, there is no adjustment or “fitting” necessary. Indexing or replacing an insert takes just seconds. Simply loosen its retaining screw, turn the insert to its new position and tighten the screw.

The durability of the carbide combined with the low impact, shear cutting action mean the inserts have an extremely long life, far exceeding that of straight blades. The potential life span of these carbide inserts means that many woodworkers may go years before having to index them. Should a hidden piece of metal be encountered and actually damage a few of the carbide inserts only the ones actually contacting the metal need to be indexed or replaced.

Tables

At 7

The outfeed table height is adjusted with a handwheel mounted below the table. A

The infeed table height

adjustments are truly unique. The

handle can be moved up and down for coarse height changes or, after snugging the locking knob (to the left) the long handle can be rotated to make very fine, precise infeed table height adjustments.