23.Install blade tension lever (Fig. 11a) and tighten the set screws, using a 3mm hex wrench. The movement of the blade tension lever is explained under “Changing Blades”.

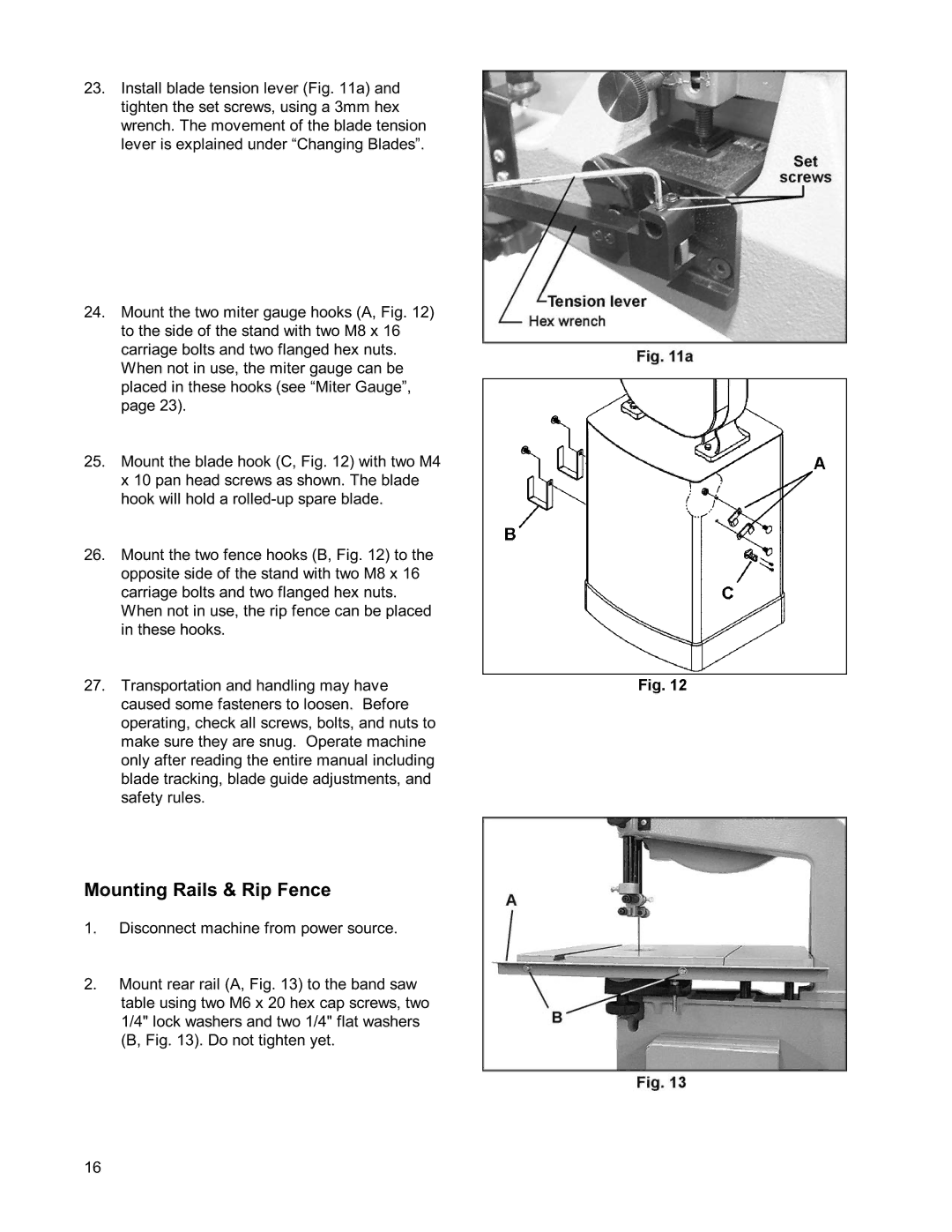

24.Mount the two miter gauge hooks (A, Fig. 12) to the side of the stand with two M8 x 16 carriage bolts and two flanged hex nuts. When not in use, the miter gauge can be placed in these hooks (see “Miter Gauge”, page 23).

25.Mount the blade hook (C, Fig. 12) with two M4 x 10 pan head screws as shown. The blade hook will hold a

26.Mount the two fence hooks (B, Fig. 12) to the opposite side of the stand with two M8 x 16 carriage bolts and two flanged hex nuts. When not in use, the rip fence can be placed in these hooks.

27.Transportation and handling may have caused some fasteners to loosen. Before operating, check all screws, bolts, and nuts to make sure they are snug. Operate machine only after reading the entire manual including blade tracking, blade guide adjustments, and safety rules.

Mounting Rails & Rip Fence

1.Disconnect machine from power source.

2.Mount rear rail (A, Fig. 13) to the band saw table using two M6 x 20 hex cap screws, two 1/4" lock washers and two 1/4" flat washers (B, Fig. 13). Do not tighten yet.

16