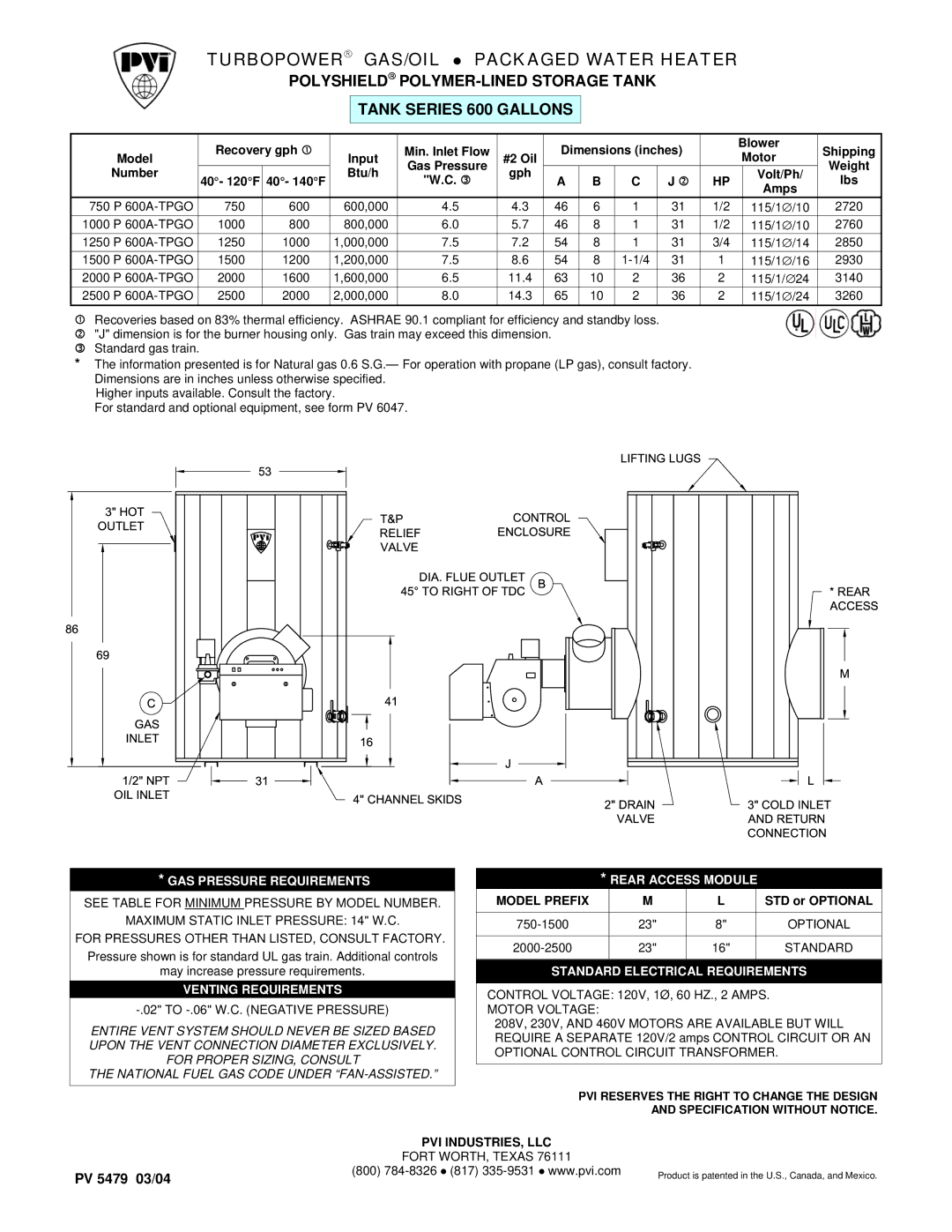

1500P600A-TPGO, 1000P600A-TPGO, 2000P600A-TPGO, 2500P600A-TPGO, 1250P600A-TPGO specifications

PVI Industries is a recognized leader in the field of advanced industrial technology and manufacturing solutions. Among their innovative product line, the PVI Industries 1000P600A-TPGO, 1500P600A-TPGO, 2500P600A-TPGO, 1250P600A-TPGO, and 750P600A-TPGO units stand out for their robust performance and superior engineering.These models cater to various industrial applications, offering exceptional reliability and efficiency. The PVI Industries 1000P600A-TPGO, for instance, is designed for compact operations while delivering high output power, making it ideal for smaller facilities or specific sectors requiring efficient energy use. With a focus on energy conservation, this model includes advanced features that minimize waste.

The 1500P600A-TPGO and 1250P600A-TPGO models further enhance PVI’s commitment to performance. They incorporate cutting-edge technologies, such as real-time monitoring and smart control systems, allowing operators to precisely manage energy consumption and operational efficiency. These technologies not only optimize output but also reduce wear and tear on components, ensuring longer lifespan and lower maintenance costs.

For larger-scale needs, the 2500P600A-TPGO offers substantial power with enhanced thermal management systems that ensure stable operation under high loads. Its design integrates noise-reduction technologies, providing a quieter operation suitable for environments where noise pollution is a concern.

Furthermore, the 750P600A-TPGO serves as a versatile solution for medium-sized applications, combining essential features of its larger counterparts with a compact design. It allows for easy integration into existing systems while maintaining high efficiency and performance.

In terms of characteristics, all these models share common traits such as high durability, resistance to harsh industrial conditions, and compliance with industry standards. They are built with advanced materials and components that withstand demanding environments, making them suitable for a variety of industrial sectors, including manufacturing, energy, and construction.

PVI Industries has equipped these products with user-friendly interfaces and diagnostic tools that enhance operational transparency. This allows users to quickly identify and troubleshoot issues, minimizing downtime. Overall, the PVI Industries lineup of 1000P600A-TPGO, 1500P600A-TPGO, 2500P600A-TPGO, 1250P600A-TPGO, and 750P600A-TPGO reflects the company's commitment to innovation, reliability, and excellence in industrial technology.