COLD WATER RUN

For the same reason stated for Cold Water Starts, it is even more important to provide protection against condensation from cold inlet water on systems where the return water temperature to the boiler will always be below the acceptable minimum. Raypak’s Cold Water Run system utilizes a

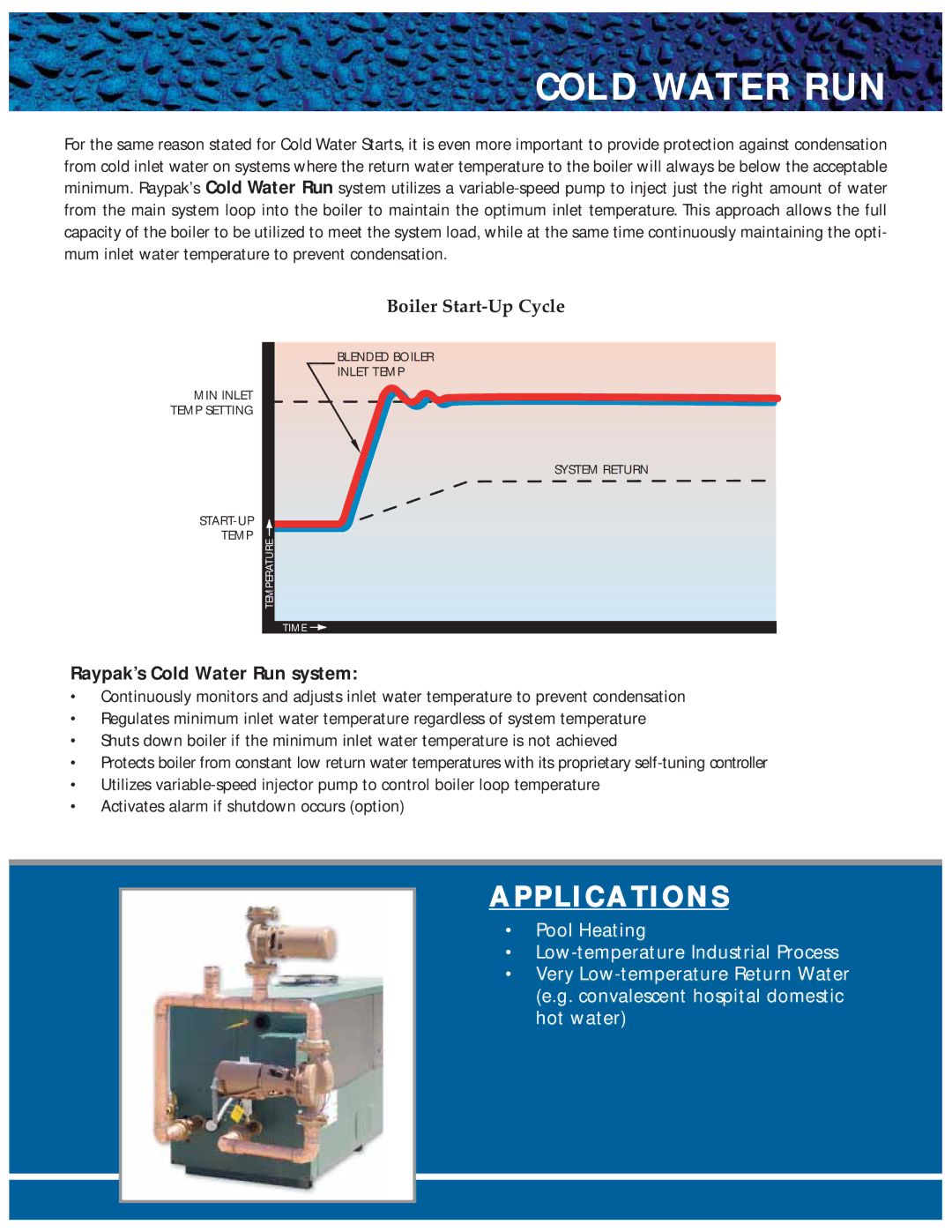

Boiler Start-Up Cycle

BLENDED BOILER

INLET TEMP

MIN INLET

TEMP SETTING

SYSTEM RETURN

TEMP

TEMPERATURE

TIME ![]()

Raypak’s Cold Water Run system:

•Continuously monitors and adjusts inlet water temperature to prevent condensation

•Regulates minimum inlet water temperature regardless of system temperature

•Shuts down boiler if the minimum inlet water temperature is not achieved

•Protects boiler from constant low return water temperatures with its proprietary

•Utilizes

•Activates alarm if shutdown occurs (option)

APPLICATIONS

• Pool Heating

•

• Very

(e.g. convalescent hospital domestic

hot water)