182-400 specifications

The Raypak 182-400 is a powerful and efficient pool heater designed to provide reliable heating for both residential and commercial swimming pools and spas. Renowned for its robust construction and advanced technology, the Raypak 182-400 offers a blend of performance, efficiency, and user-friendliness that distinguishes it in the competitive pool heating market.One of the key features of the Raypak 182-400 is its impressive heating capacity. With a BTU output of 400,000, this heater can rapidly raise the temperature of large volumes of water, making it suitable for pools of various sizes. Whether for a quick midnight swim or preparing for a pool party, the Raypak 182-400 delivers prompt and consistent results.

Energy efficiency is another standout characteristic of this heater. The Raypak 182-400 is designed to maximize heat retention and minimize fuel consumption, which helps to lower overall operating costs. Utilizing a high-performance titanium heat exchanger, the heater ensures optimal thermal efficiency, delivering heat quickly while maintaining energy savings. This focus on efficiency not only benefits owners financially but also promotes environmentally friendly operation.

Installation and operation of the Raypak 182-400 are simplified through its user-friendly control system. The unit features an intuitive digital display that allows easy programming and monitoring of the heater's performance. Users can easily adjust temperature settings, timer functions, and diagnostics, enhancing overall convenience.

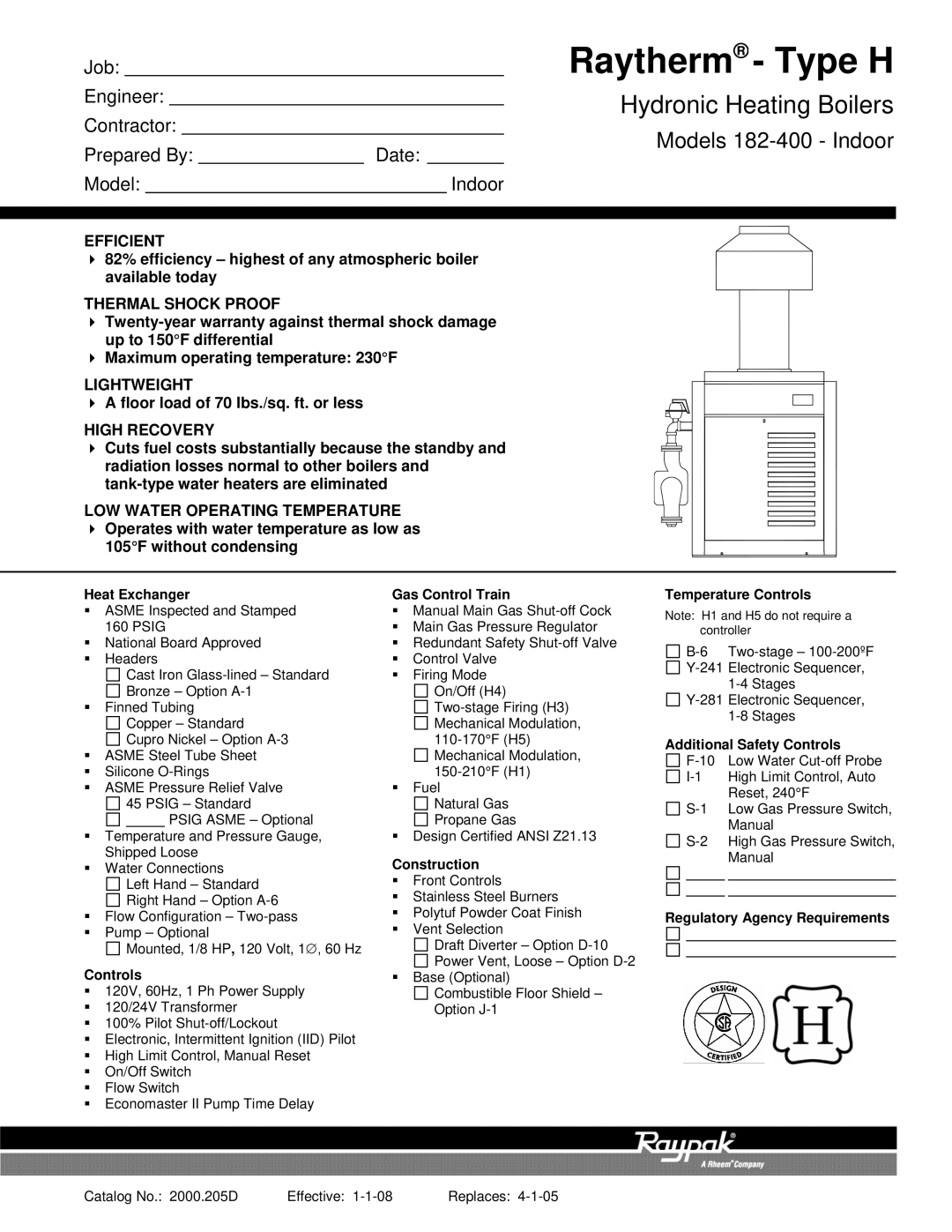

Durability is paramount for outdoor appliances like pool heaters. The Raypak 182-400 boasts a rugged, weather-resistant cabinet that protects against the elements, ensuring longevity even in harsh conditions. Additionally, the heavy-duty construction incorporates corrosion-resistant materials, making it ideal for use in various climates and environments.

Safety features are also a top priority with the Raypak 182-400. The unit includes multiple safeguards such as a high limit switch and a pressure switch to prevent overheating and ensure safe operation. These elevated safety standards offer peace of mind for users.

In summary, the Raypak 182-400 stands out in the pool heating landscape due to its powerful heating capacity, energy efficiency, user-friendly controls, durable construction, and comprehensive safety features. This heater is an excellent investment for those looking to enjoy a consistently warm swim, making it a popular choice among pool and spa owners alike. Whether for long-term home use or commercial applications, the Raypak 182-400 delivers exceptional performance and reliability.