Finned Water-Tube Water Heaters specifications

Raypak Finned Water-Tube Water Heaters are renowned for their efficiency, durability, and advanced technology, making them a preferred choice for both residential and commercial applications. These heaters are designed to provide hot water consistently and reliably, catering to a wide range of temperature requirements.One of the primary features of Raypak Finned Water-Tube Water Heaters is their unique finned-tube design. This design increases the surface area of the heat exchanger, allowing for maximum heat transfer and improved thermal efficiency. The finned tubes facilitate superior heat exchange with the water flowing through them, ensuring that hot water is readily available even during periods of high demand.

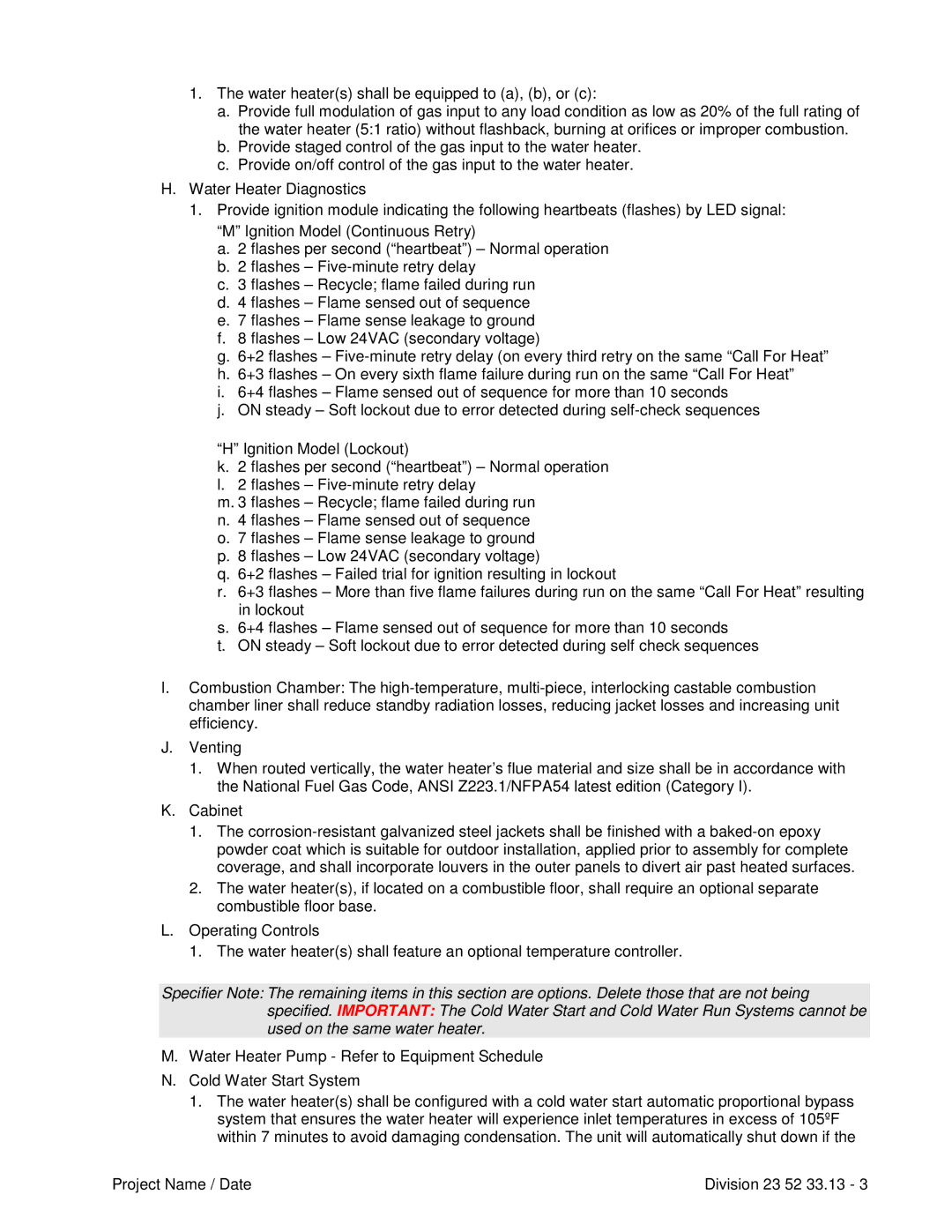

Raypak integrates advanced technologies in their water heaters to enhance performance and energy efficiency. The units are equipped with advanced control systems that allow for precise temperature regulation, reducing energy consumption and preventing overheating. Additionally, many models feature modulating burners, which adjust the firing rate based on the heating demand, ensuring optimal efficiency and reduced emissions.

Durability is another hallmark of Raypak's engineering. The water-tube construction is designed to withstand high pressures and temperatures, making these heaters suitable for high-demand applications. The units are constructed with high-quality materials that resist corrosion and wear, ensuring a long operational life with minimal maintenance.

Raypak also prioritizes safety in their heater designs. Features such as automatic shut-off valves, flame detection systems, and pressure relief valves are incorporated to ensure safe operation in various conditions. These safety mechanisms protect both the user and the equipment, adding peace of mind to the investment.

Energy efficiency ratings for Raypak Finned Water-Tube Water Heaters are typically high, qualifying for energy rebates and incentives in many areas. This efficiency translates to lower operating costs and environmental benefits, aligning with the global shift towards sustainable practices.

In summary, Raypak Finned Water-Tube Water Heaters stand out for their innovative design, advanced technology, and robust safety measures. They provide exceptional heating performance suited for myriad applications, making them a reliable choice for consumers looking to invest in high-quality water heating solutions. With ongoing advancements in technology, Raypak continues to lead the way in delivering efficient and effective water heating systems that meet modern demands.