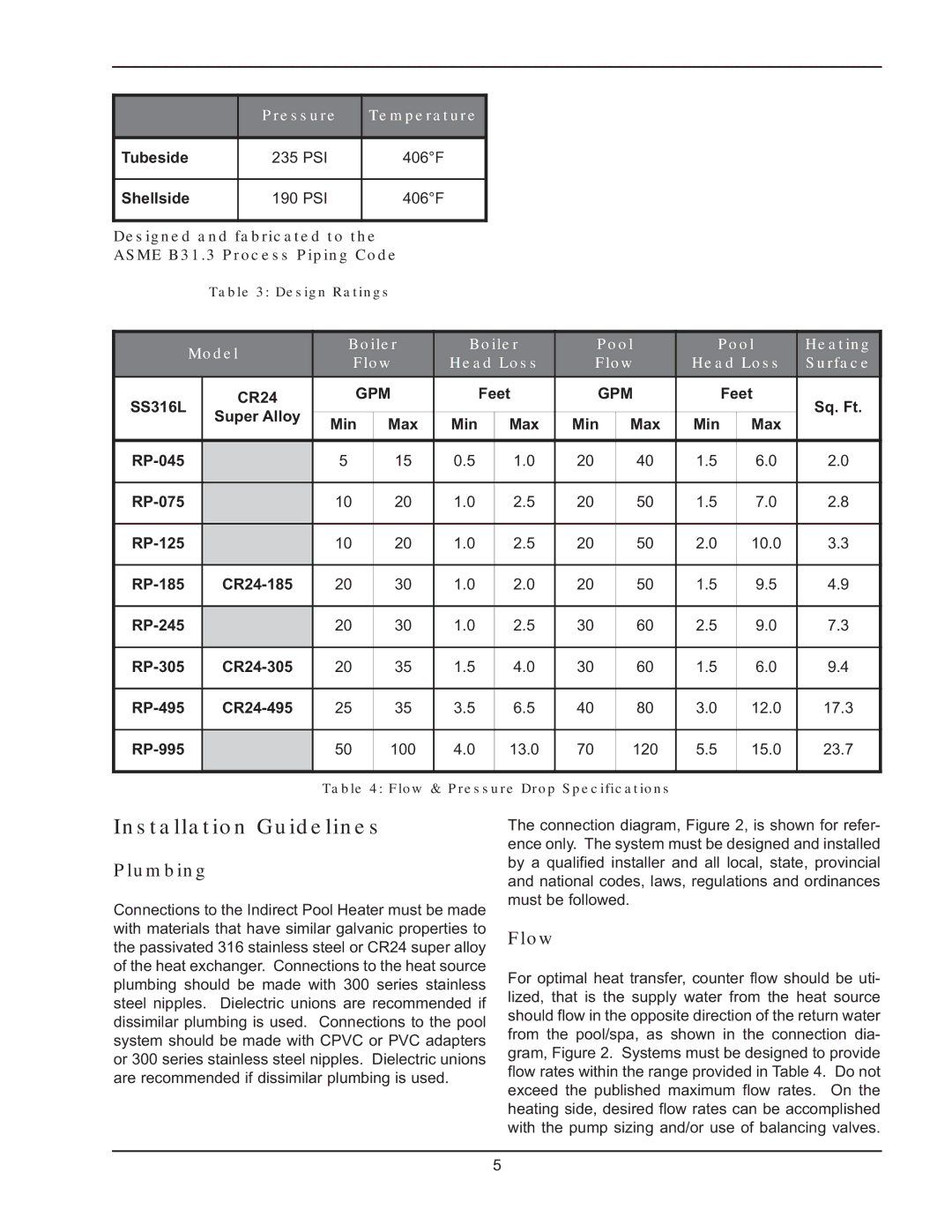

RP-995, CR24-185, RP-045, CR24-495 specifications

Raypak is a reputable name in the heating industry, known for its commitment to quality and innovation. Among its impressive lineup of products are the CR24-495, RP-045, CR24-185, and RP-995 models, each designed to cater to specific heating needs while ensuring efficiency and reliability.The Raypak CR24-495 is a high-capacity, commercial-grade boiler renowned for its robust construction and exceptional performance. One of its main features is the use of a stainless steel heat exchanger, which enhances durability, provides excellent heat transfer, and minimizes the risk of corrosion. The CR24-495 also incorporates an advanced modulating gas burner, which adjusts the heat output based on demand, leading to fuel savings and consistent temperature control.

In contrast, the RP-045 model is tailored for residential applications, combining efficient heating with user-friendly features. This boiler is equipped with a digital LCD display that provides real-time system information and diagnostics, simplifying maintenance and operation. The RP-045 utilizes a compact design, making installation easy and convenient for smaller spaces. Its whisper-quiet operation ensures a peaceful environment, ideal for home settings.

The CR24-185 is another exceptional offering by Raypak, specifically designed for moderate commercial applications. This unit boasts a high thermal efficiency rating, ensuring maximum heat output while minimizing energy consumption. The CR24-185 also features a built-in temperature control system, which allows for precise temperature settings. Its versatility makes it suitable for various applications, including swimming pools and hydronic heating systems.

Finally, the RP-995 stands out as a powerhouse in the Raypak portfolio, capable of delivering high performance for larger heating demands. The RP-995 includes advanced control systems that allow for integration with building management systems, providing enhanced monitoring and control capabilities. This model employs a state-of-the-art combustion technology that ensures optimal fuel efficiency and reduced emissions, aligning with modern environmental standards.

In summary, Raypak's CR24-495, RP-045, CR24-185, and RP-995 models exemplify the brand's commitment to delivering innovative heating solutions. With advanced features such as high-efficiency heat exchangers, user-friendly controls, and robust construction, these models cater to a wide range of heating requirements, ensuring that customers enjoy reliable performance and long-term value. Whether for residential or commercial applications, Raypak continues to lead the way in heating technology.