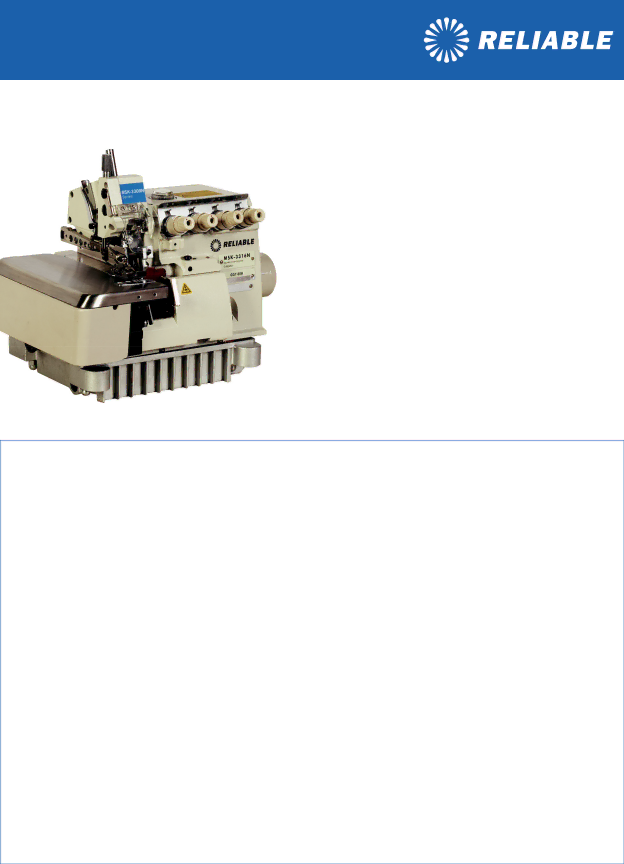

MSK-3316N specifications

The Reliable MSK-3316N is a multifunctional fabric pressing machine that excels in delivering high-quality finishing for a variety of textiles. This machine is engineered to meet the demands of modern garment production, providing efficiency, speed, and precision in pressing operations.One of the standout features of the MSK-3316N is its advanced steam generation technology. The machine utilizes a powerful steam system that produces high-pressure steam, allowing for quick and effective removal of wrinkles from fabric. This is particularly beneficial for delicate textiles that require gentle handling. The steam is evenly distributed, ensuring that all areas of the garment receive the necessary treatment without causing damage.

The MSK-3316N also boasts an ergonomic design, making it user-friendly for operators. The adjustable height feature accommodates different working environments and user preferences, reducing operator fatigue during long hours of usage. The machine is equipped with a large pressing surface, which allows for the pressing of various garment sizes and shapes, enhancing versatility in operations.

In terms of technology, the MSK-3316N is fitted with an intuitive control panel that streamlines operation. The user-friendly interface features programmable settings, allowing operators to store and recall specific pressing parameters for different fabrics and styles. This capability not only saves time but also ensures consistency across production runs.

Another notable characteristic of the MSK-3316N is its safety features. The machine is designed with automatic shut-off functions to prevent overheating and potential accidents. Additionally, the construction materials are durable, ensuring longevity and reducing maintenance needs.

The Reliable MSK-3316N is also energy-efficient, making it an environmentally friendly choice for production facilities. Its innovative heating elements and steam technology minimize energy consumption while maximizing operational effectiveness.

In summary, the Reliable MSK-3316N stands out as a reliable choice for garment pressing, offering an array of features that enhance efficiency and maintain product quality. Its advanced steam technology, ergonomic design, user-friendly controls, safety features, and energy efficiency make it an invaluable asset for any textile production setup.