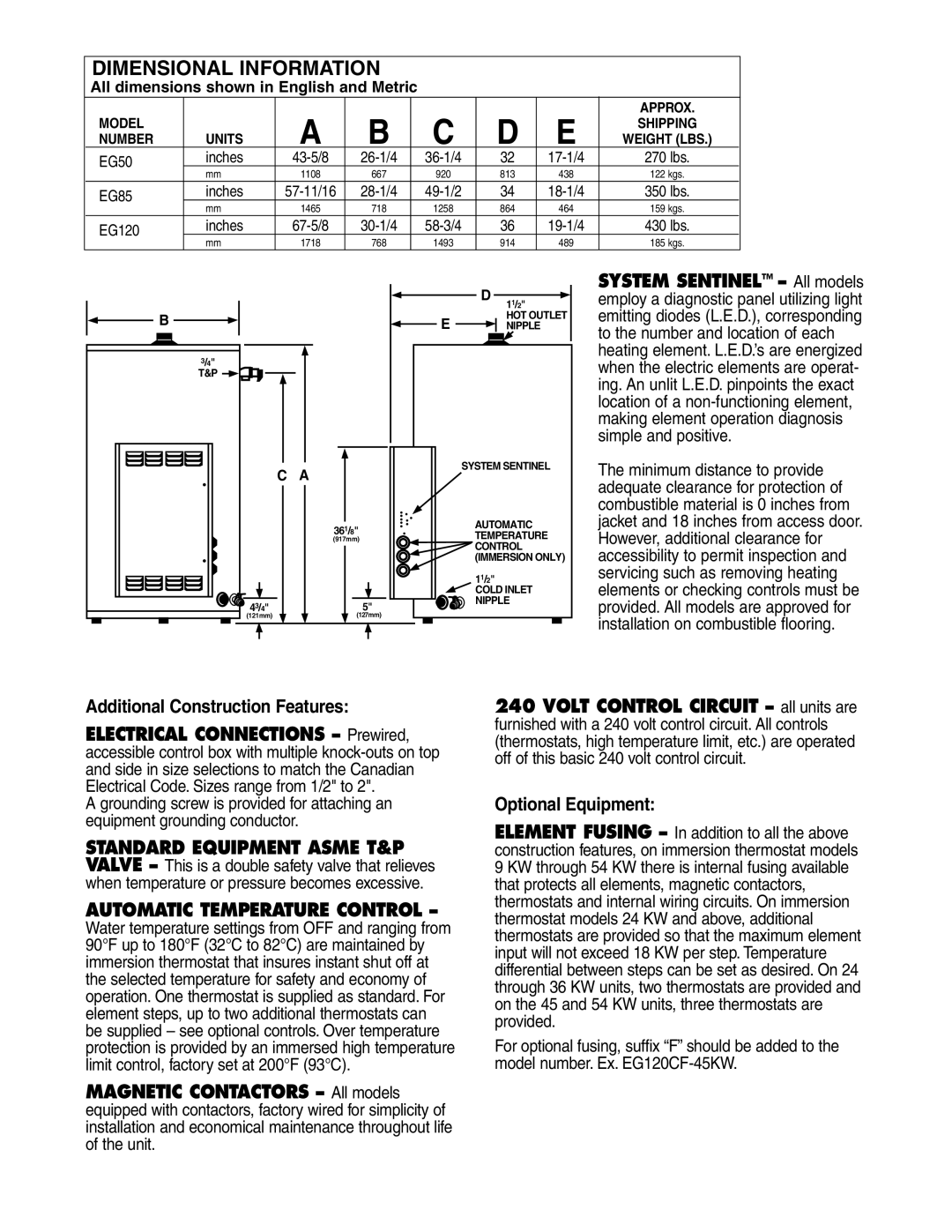

DIMENSIONAL INFORMATION

All dimensions shown in English and Metric

|

|

| A | B | C | D | E | APPROX. | |

| MODEL |

| SHIPPING | ||||||

| NUMBER | UNITS | WEIGHT (LBS.) |

| |||||

| EG50 | inches | 32 | 270 lbs. |

| ||||

| mm | 1108 | 667 | 920 | 813 | 438 | 122 kgs. |

| |

|

| ||||||||

| EG85 | inches | 34 | 350 lbs. |

| ||||

| mm | 1465 | 718 | 1258 | 864 | 464 | 159 kgs. |

| |

|

| ||||||||

| EG120 | inches |

|

|

| 36 |

| 430 lbs. |

|

| mm | 1718 | 768 | 1493 | 914 | 489 | 185 kgs. | ||

|

| ||||||||

B |

|

3/4" |

|

T&P |

|

C | A |

| 361/8" |

| (917mm) |

43/4" | 5" |

(121mm) | (127mm) |

![]() D

D

11/2"

HOT OUTLET

E ![]() NIPPLE

NIPPLE

SYSTEM SENTINEL

AUTOMATIC TEMPERATURE ![]() CONTROL (IMMERSION ONLY)

CONTROL (IMMERSION ONLY)

11/2"

COLD INLET NIPPLE

SYSTEM SENTINEL™ – All models employ a diagnostic panel utilizing light emitting diodes (L.E.D.), corresponding to the number and location of each heating element. L.E.D.’s are energized when the electric elements are operat- ing. An unlit L.E.D. pinpoints the exact location of a

The minimum distance to provide adequate clearance for protection of combustible material is 0 inches from jacket and 18 inches from access door. However, additional clearance for accessibility to permit inspection and servicing such as removing heating elements or checking controls must be provided. All models are approved for installation on combustible flooring.

Additional Construction Features:

ELECTRICAL CONNECTIONS – Prewired, accessible control box with multiple

A grounding screw is provided for attaching an equipment grounding conductor.

STANDARD EQUIPMENT ASME T&P VALVE – This is a double safety valve that relieves

when temperature or pressure becomes excessive.

AUTOMATIC TEMPERATURE CONTROL –

Water temperature settings from OFF and ranging from 90°F up to 180°F (32°C to 82°C) are maintained by immersion thermostat that insures instant shut off at the selected temperature for safety and economy of operation. One thermostat is supplied as standard. For element steps, up to two additional thermostats can be supplied – see optional controls. Over temperature protection is provided by an immersed high temperature limit control, factory set at 200°F (93°C).

MAGNETIC CONTACTORS – All models equipped with contactors, factory wired for simplicity of installation and economical maintenance throughout life of the unit.

240 VOLT CONTROL CIRCUIT – all units are furnished with a 240 volt control circuit. All controls (thermostats, high temperature limit, etc.) are operated off of this basic 240 volt control circuit.

Optional Equipment:

ELEMENT FUSING – In addition to all the above construction features, on immersion thermostat models 9 KW through 54 KW there is internal fusing available that protects all elements, magnetic contactors, thermostats and internal wiring circuits. On immersion thermostat models 24 KW and above, additional thermostats are provided so that the maximum element input will not exceed 18 KW per step. Temperature differential between steps can be set as desired. On 24 through 36 KW units, two thermostats are provided and on the 45 and 54 KW units, three thermostats are provided.

For optional fusing, suffix “F” should be added to the model number. Ex.