ASSEMBLY

MOUNTING MITER SAW

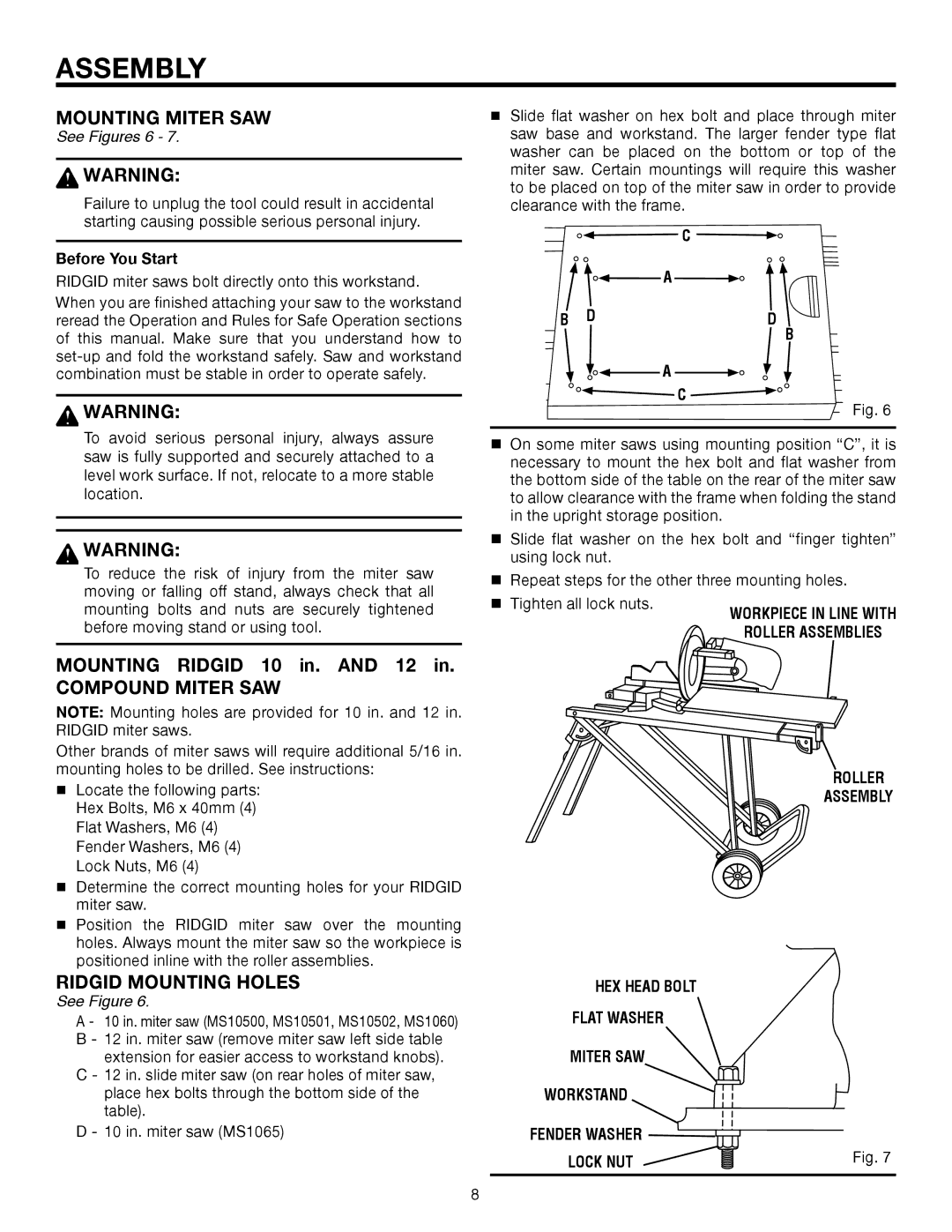

See Figures 6 - 7.

![]() WARNING:

WARNING:

Failure to unplug the tool could result in accidental starting causing possible serious personal injury.

Before You Start

RIDGID miter saws bolt directly onto this workstand.

When you are finished attaching your saw to the workstand reread the Operation and Rules for Safe Operation sections of this manual. Make sure that you understand how to

![]() WARNING:

WARNING:

To avoid serious personal injury, always assure saw is fully supported and securely attached to a level work surface. If not, relocate to a more stable location.

WARNING:

To reduce the risk of injury from the miter saw moving or falling off stand, always check that all mounting bolts and nuts are securely tightened before moving stand or using tool.

nSlide flat washer on hex bolt and place through miter saw base and workstand. The larger fender type flat washer can be placed on the bottom or top of the miter saw. Certain mountings will require this washer to be placed on top of the miter saw in order to provide clearance with the frame.

|

| C |

|

| A |

B | D | D |

|

| B |

|

| A |

|

| C |

|

| Fig. 6 |

nOn some miter saws using mounting position “C”, it is necessary to mount the hex bolt and flat washer from the bottom side of the table on the rear of the miter saw to allow clearance with the frame when folding the stand in the upright storage position.

nSlide flat washer on the hex bolt and “finger tighten” using lock nut.

nRepeat steps for the other three mounting holes.

nTighten all lock nuts.

MOUNTING RIDGID 10 in. AND 12 in.

COMPOUND MITER SAW

NOTE: Mounting holes are provided for 10 in. and 12 in. RIDGID miter saws.

Other brands of miter saws will require additional 5/16 in. mounting holes to be drilled. See instructions:

nLocate the following parts: Hex Bolts, M6 x 40mm (4) Flat Washers, M6 (4)

Fender Washers, M6 (4) Lock Nuts, M6 (4)

nDetermine the correct mounting holes for your RIDGID miter saw.

nPosition the RIDGID miter saw over the mounting holes. Always mount the miter saw so the workpiece is positioned inline with the roller assemblies.

RIDGID MOUNTING HOLES

See Figure 6.

A - 10 in. miter saw (MS10500, MS10501, MS10502, MS1060) B - 12 in. miter saw (remove miter saw left side table extension for easier access to workstand knobs).

C - 12 in. slide miter saw (on rear holes of miter saw, place hex bolts through the bottom side of the table).

D - 10 in. miter saw (MS1065)

HEX HEAD BOLT |

|

FLAT WASHER |

|

MITER SAW |

|

WORKSTAND |

|

FENDER WASHER |

|

LOCK NUT | Fig. 7 |

|

8