ASSEMBLY

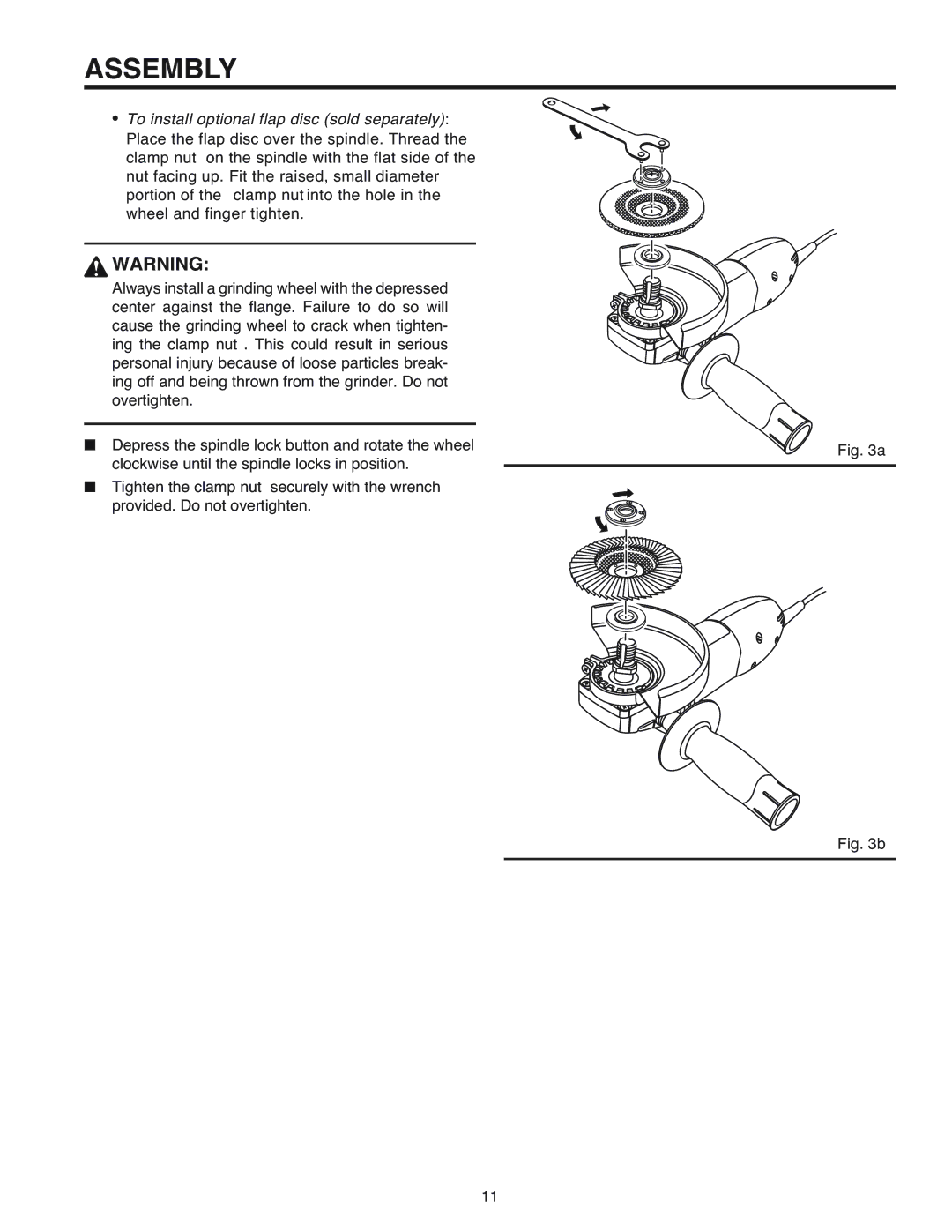

•To install optional flap disc (sold separately):

Place the flap disc over the spindle. Thread the clamp nut on the spindle with the flat side of the nut facing up. Fit the raised, small diameter portion of the clamp nut into the hole in the wheel and finger tighten.

![]() WARNING:

WARNING:

Always install a grinding wheel with the depressed center against the flange. Failure to do so will cause the grinding wheel to crack when tighten- ing the clamp nut . This could result in serious personal injury because of loose particles break- ing off and being thrown from the grinder. Do not overtighten.

■Depress the spindle lock button and rotate the wheel clockwise until the spindle locks in position.

■Tighten the clamp nut securely with the wrench provided. Do not overtighten.

Fig. 3a

Fig. 3b

11