Removal of Debris or Soot Deposits

Debris from any source or any soot formed shall require removal. Allow the appliance to cool sufficiently before removing all of the coals and firebed components for cleaning purposes. Once all the ceramics are removed from the firebed check that no debris is located in the burner slots. If any debris is present it may easily be removed by using a small piece of thin cardboard to ease out any foreign matter. Be sure to remove the cardboard after use. To ensure that the release of fibres from these RCF articles is kept to a minimum, during installation and servicing we recommend that you use a HEPA filtered vacuum to remove any dust and soot accumulated in and around the fire before and after working on the fire. When replacing these articles we recommend that the replaced items are not broken up, but are sealed within heavy duty polythene bags, clearly labelled as RCF waste. This is not classified as "hazardous waste" and may be disposed of at a tipping site licensed for the disposal of industrial waste. Protective clothing is not required when handling these articles, but we recommend you follow the normal hygiene rules of not smoking, eating or drinking in the work area and always wash your hands before eating or drinking. Any sooty deposit an the thermocouple probe can be cleaned off using a non fluffy cloth. DO NOT USE ABRASIVE MATERIALS

Servicing Components below the Burner Assembly

TURN OFF THE GAS SUPPLY TO THE APPLIANCE

Remove coals, coal support and front simulated coal. To gain access to components below the burner assembly the burner assembly has to be removed from the vent box case by disconnecting the gas supply at the inlet elbow and unscrewing the two screws at the base of the facia panel. The assembly should be lifted approximately 20mm at the front to clear the fixing flange. When refitting observe that the two feet at the rear of the assembly locate under the two lugs formed in the base of the box assembly.

i)TO CLEAN OR REPLACE THE INJECTOR: Unscrew the compression nut connecting the gas supply to the elbow injector while supporting the injector to prevent distortion of the framework. Unscrew and remove the gas supply tube from the gas control valve, hold the injector lock nut with a spanner and rotate the injector. Replace in reverse order.

ii)TO REPLACE THE GAS CONTROL (Tap/FSD): Disconnect the three gas pipes and the thermocouple from the control. . Pull the control knob from the spindle; undo the two screws securing the control bracket to the main assembly. The tap may now be withdrawn. Replace in the reverse order.

iii)TO REPLACE THE

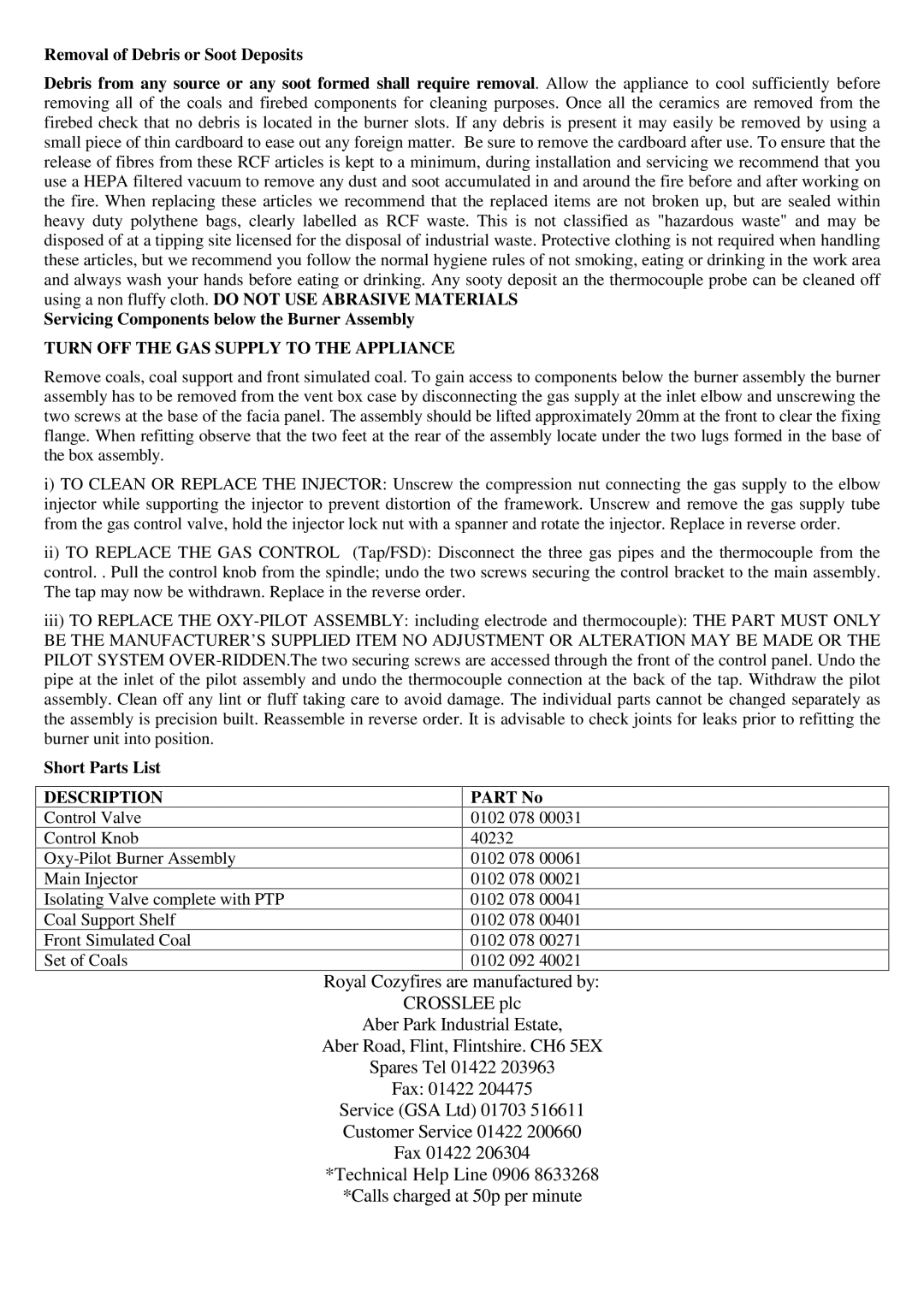

Short Parts List

DESCRIPTION

Control Valve

Control Knob

Main Injector

Isolating Valve complete with PTP

Coal Support Shelf

Front Simulated Coal

Set of Coals

PART No

0102 078 00031

40232

0102 078 00061

0102 078 00021

0102 078 00041

0102 078 00401

0102 078 00271

0102 092 40021

Royal Cozyfires are manufactured by:

CROSSLEE plc

Aber Park Industrial Estate,

Aber Road, Flint, Flintshire. CH6 5EX

Spares Tel 01422 203963

Fax: 01422 204475

Service (GSA Ltd) 01703 516611 Customer Service 01422 200660 Fax 01422 206304

*Technical Help Line 0906 8633268

*Calls charged at 50p per minute