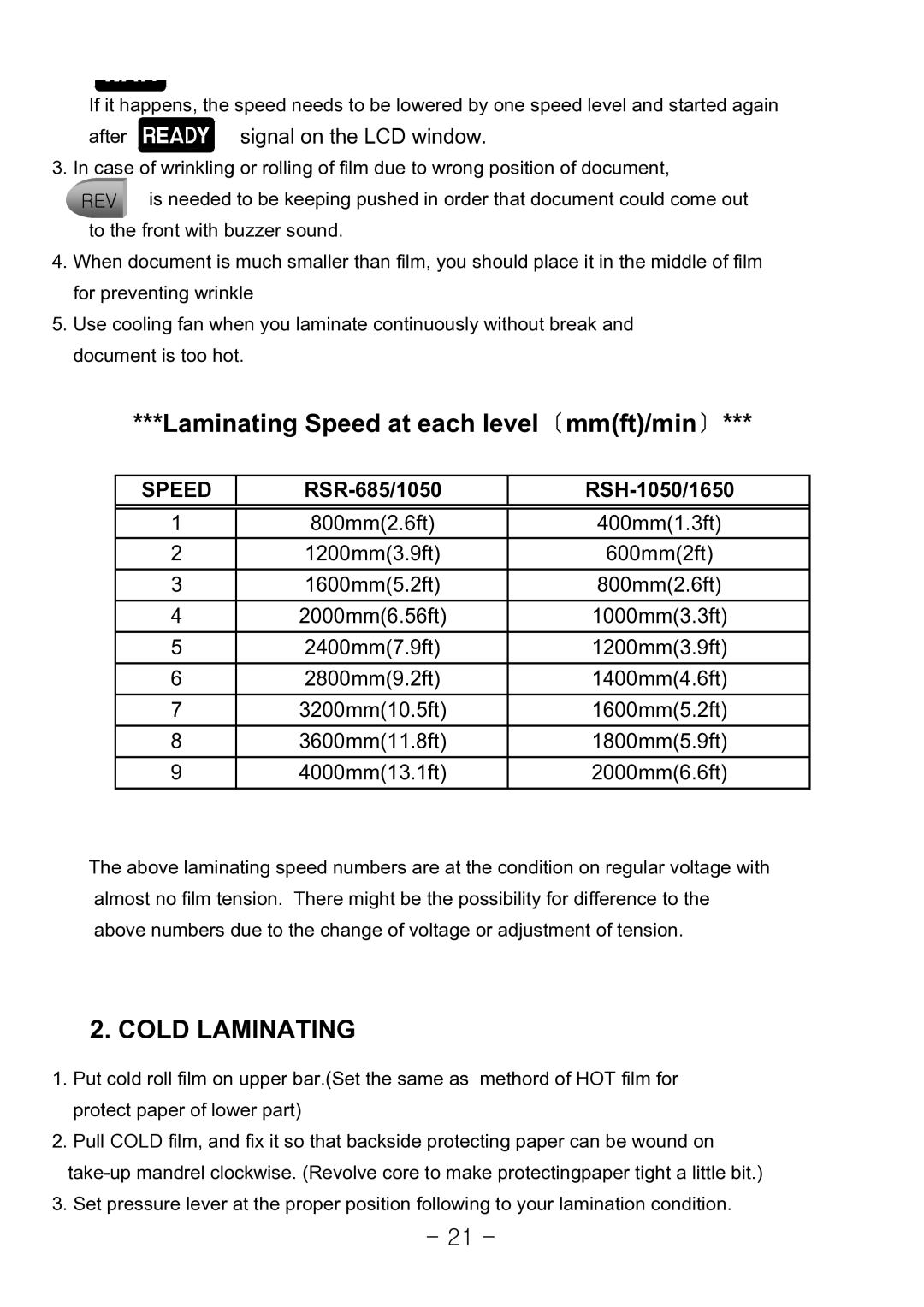

1050, 1650, RSH-1050, RSR-685 specifications

The Royal Sovereign RSR-685, RSH-1050, RSH-1650, and RSH-1050 are a series of high-quality laminating and finishing machines designed for both commercial and industrial applications. Each model offers unique features and capabilities, making them ideal for various print finishing tasks.Starting with the RSR-685, this compact and efficient laminator is engineered for small to medium print runs. One of its standout features is the ability to laminate in both hot and cold processes, providing versatility for different types of media. The machine includes an intuitive control panel, enabling users to set precise temperature and speed settings easily. Additionally, the RSR-685 utilizes a high-quality silicon roller that ensures even heat distribution, minimizing the risk of defects during the laminating process. With a maximum lamination width of 27 inches and a top speed of 16.4 feet per minute, it is suitable for a variety of applications, including documents, photographs, and other printed materials.

Next, the RSH-1050 model is built for those requiring higher production capabilities. This machine boasts an impressive lamination width of up to 39 inches, accommodating larger materials. The RSH-1050 is designed with advanced features like a programmable digital control system and an automatic feed system, enhancing operational efficiency. The built-in safety features prevent overheating and reduce the risk of injury, making it a reliable choice for any busy workspace.

The RSH-1650 model further expands on these features, offering a greater lamination width of 63 inches, specifically catering to larger format prints. This high-speed laminator can achieve speeds of up to 33 feet per minute, which is particularly beneficial for high-volume operations. It incorporates dual rollers for consistent results and utilizes state-of-the-art technology to ensure minimal waste and maximum productivity.

Finally, the RSH-1050 offers a balance between functionality and affordability, making it a compelling option for mid-sized printing businesses. It inherits many features from its larger counterparts, including adjustable speed and temperature controls, ensuring that users can achieve optimal results tailored to their specific materials.

In conclusion, the Royal Sovereign RSR-685, RSH-1050, RSH-1650, and RSH-1050 represent a robust lineup of laminating solutions characterized by their advanced technologies, user-friendly controls, and efficient production capabilities, making them suitable for a wide array of printing and finishing needs. Whether for small runs or large-scale applications, these machines deliver quality, speed, and versatility, contributing to enhanced finishing workflows.