Wheel Shafts

Remove wheel assemblies and lubricate the axle shafts | Idler Pulley Rod |

| |

at least once a season. |

|

Cleaning Tine Area

Clean the underside of the tine shield after each use. The dirt washes off the tines easier if rinsed off immediately instead of after it dries. Always towel dry the tiller afterwards and apply a light coat of oil or silicone to prevent rusting or water damage.

IMPORTANT: Never use a "pressure washer” to clean your tiller. Water can penetrate tight areas of the tiller and its chaincase and cause serious damage to the unit.

Belt Replacement

Your tiller has been engineered with a belt made of special material (Kevlar Tensile) for longer life and better performance. It should not be replaced with an

•Disconnect and ground the spark plug wire against the engine.

•Remove the belt cover from the left side of the tiller by remove two torx screws from the top of belt cover. See Figure 8.

•Remove the hex cap nut and flat washer from the side of the belt cover and remove the self tap screw at the bottom of the front of the cover.

Torx Screws

Belt Cover

![]()

![]()

![]() Hex Cap Nut

Hex Cap Nut ![]()

![]()

![]()

![]()

![]()

![]() & Flat Washer

& Flat Washer

Self Tap Screw

Figure 8

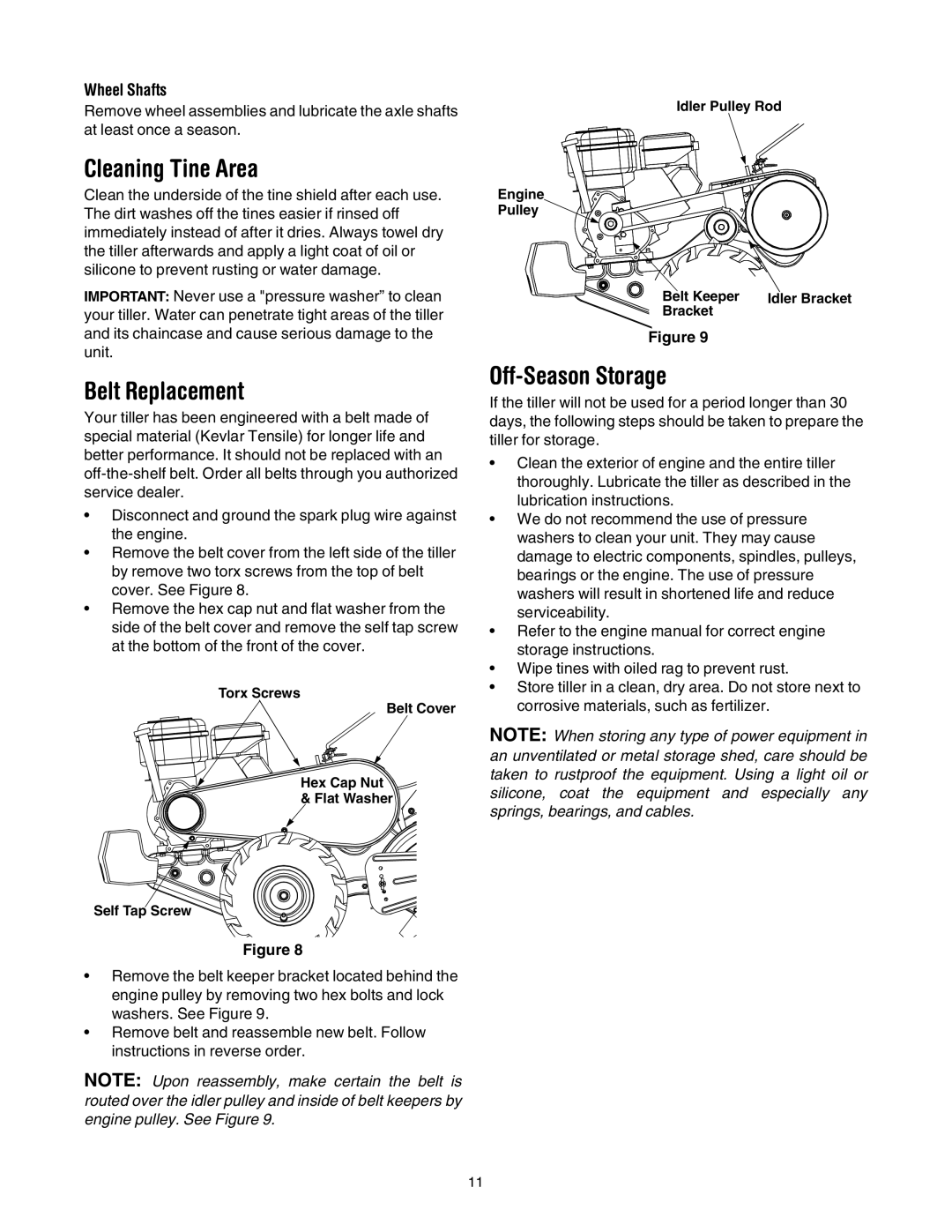

•Remove the belt keeper bracket located behind the engine pulley by removing two hex bolts and lock washers. See Figure 9.

•Remove belt and reassemble new belt. Follow instructions in reverse order.

NOTE: Upon reassembly, make certain the belt is routed over the idler pulley and inside of belt keepers by engine pulley. See Figure 9.

Engine

Pulley ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Belt Keeper | Idler Bracket |

Bracket |

|

Figure 9

Off-Season Storage

If the tiller will not be used for a period longer than 30 days, the following steps should be taken to prepare the tiller for storage.

•Clean the exterior of engine and the entire tiller thoroughly. Lubricate the tiller as described in the lubrication instructions.

•We do not recommend the use of pressure washers to clean your unit. They may cause damage to electric components, spindles, pulleys, bearings or the engine. The use of pressure washers will result in shortened life and reduce serviceability.

•Refer to the engine manual for correct engine storage instructions.

•Wipe tines with oiled rag to prevent rust.

•Store tiller in a clean, dry area. Do not store next to corrosive materials, such as fertilizer.

NOTE: When storing any type of power equipment in an unventilated or metal storage shed, care should be taken to rustproof the equipment. Using a light oil or silicone, coat the equipment and especially any springs, bearings, and cables.

11