13.Install the hopper mounting brackets (p/n 451512 & p/n 451595) to the outside of the frame on the rear of the machine using

14.Install the catcher support bracket onto the rear of the machine and secure with

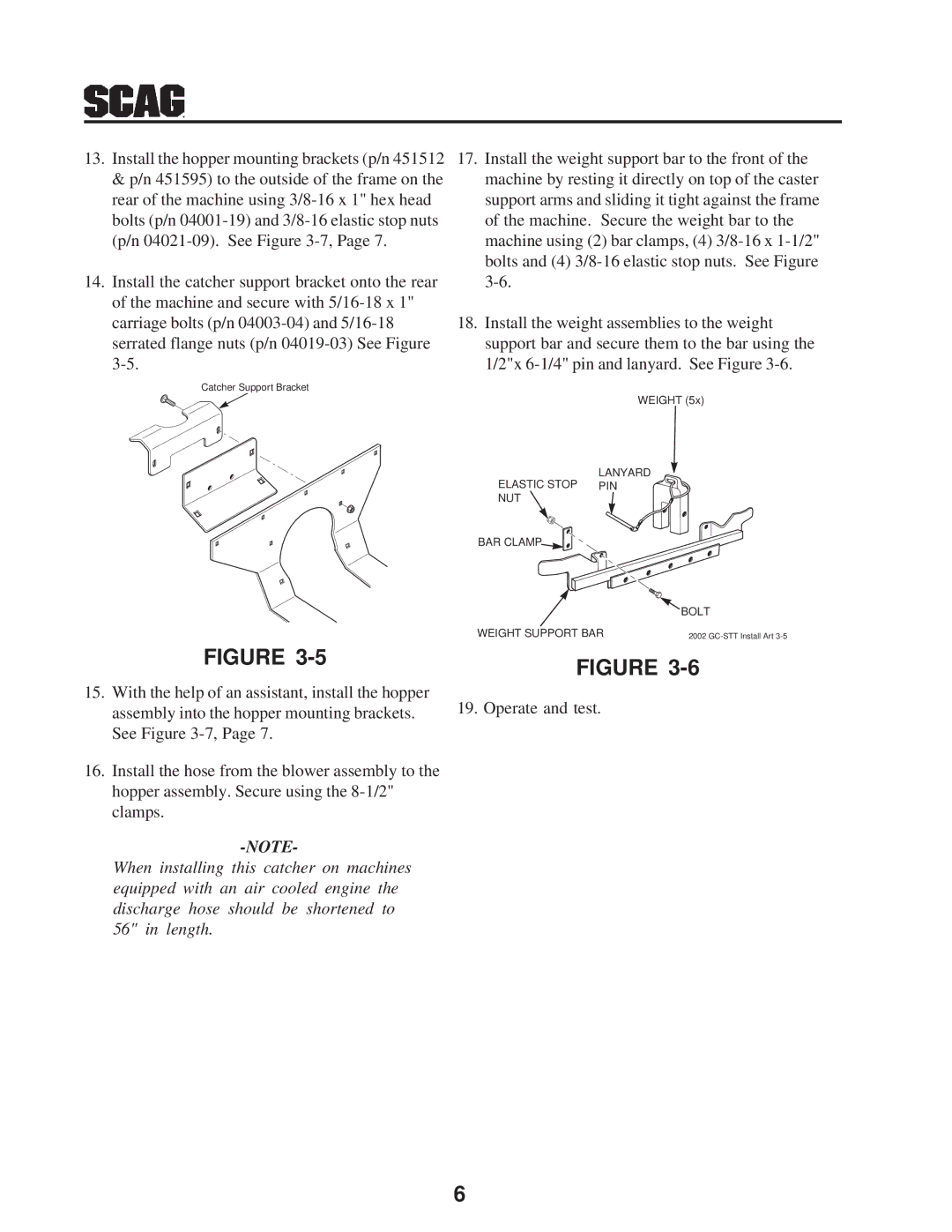

17.Install the weight support bar to the front of the machine by resting it directly on top of the caster support arms and sliding it tight against the frame of the machine. Secure the weight bar to the machine using (2) bar clamps, (4)

18.Install the weight assemblies to the weight support bar and secure them to the bar using the 1/2"x

Catcher Support Bracket

WEIGHT (5x)

FIGURE

15.With the help of an assistant, install the hopper assembly into the hopper mounting brackets. See Figure

16.Install the hose from the blower assembly to the hopper assembly. Secure using the

When installing this catcher on machines equipped with an air cooled engine the discharge hose should be shortened to 56" in length.

LANYARD

ELASTIC STOP PIN

NUT

BAR CLAMP![]()

| BOLT |

WEIGHT SUPPORT BAR | 2002 |

FIGURE

19. Operate and test.

6