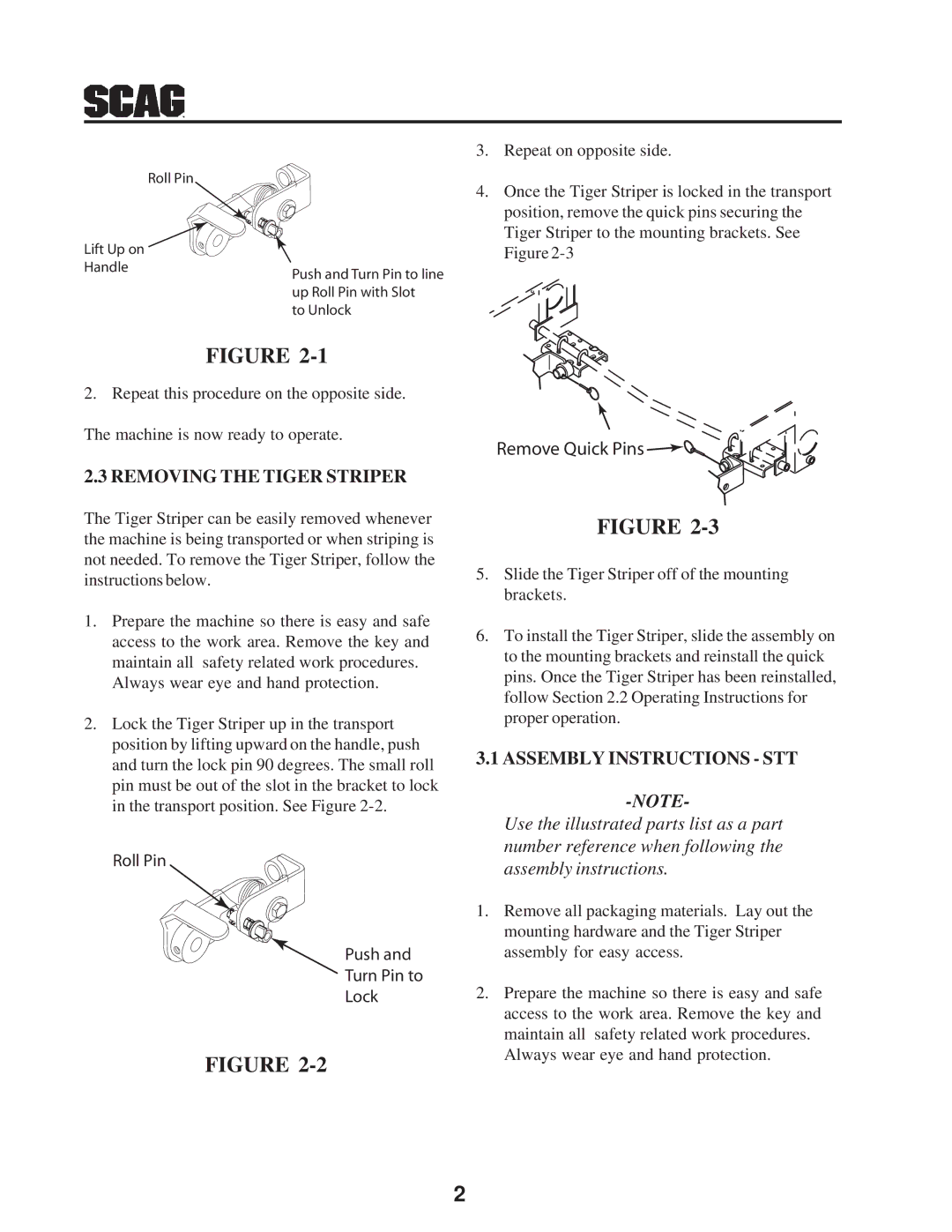

Roll Pin

3. | Repeat on opposite side. |

4. | Once the Tiger Striper is locked in the transport |

| position, remove the quick pins securing the |

| Tiger Striper to the mounting brackets. See |

Lift Up on Handle

Push and Turn Pin to line up Roll Pin with Slot

to Unlock

Figure |

FIGURE

2.Repeat this procedure on the opposite side.

The machine is now ready to operate.

2.3 REMOVING THE TIGER STRIPER

The Tiger Striper can be easily removed whenever the machine is being transported or when striping is not needed. To remove the Tiger Striper, follow the instructions below.

1.Prepare the machine so there is easy and safe access to the work area. Remove the key and maintain all safety related work procedures.

Always wear eye and hand protection.

2.Lock the Tiger Striper up in the transport position by lifting upward on the handle, push and turn the lock pin 90 degrees. The small roll pin must be out of the slot in the bracket to lock in the transport position. See Figure

Roll Pin

Push and

Turn Pin to

Lock

FIGURE

Remove Quick Pins

FIGURE

5.Slide the Tiger Striper off of the mounting brackets.

6.To install the Tiger Striper, slide the assembly on to the mounting brackets and reinstall the quick pins. Once the Tiger Striper has been reinstalled, follow Section 2.2 Operating Instructions for proper operation.

3.1 ASSEMBLY INSTRUCTIONS - STT

Use the illustrated parts list as a part number reference when following the

assembly instructions.

1.Remove all packaging materials. Lay out the mounting hardware and the Tiger Striper assembly for easy access.

2.Prepare the machine so there is easy and safe access to the work area. Remove the key and maintain all safety related work procedures.

Always wear eye and hand protection.

2