![]() 12 7/8"

12 7/8"![]()

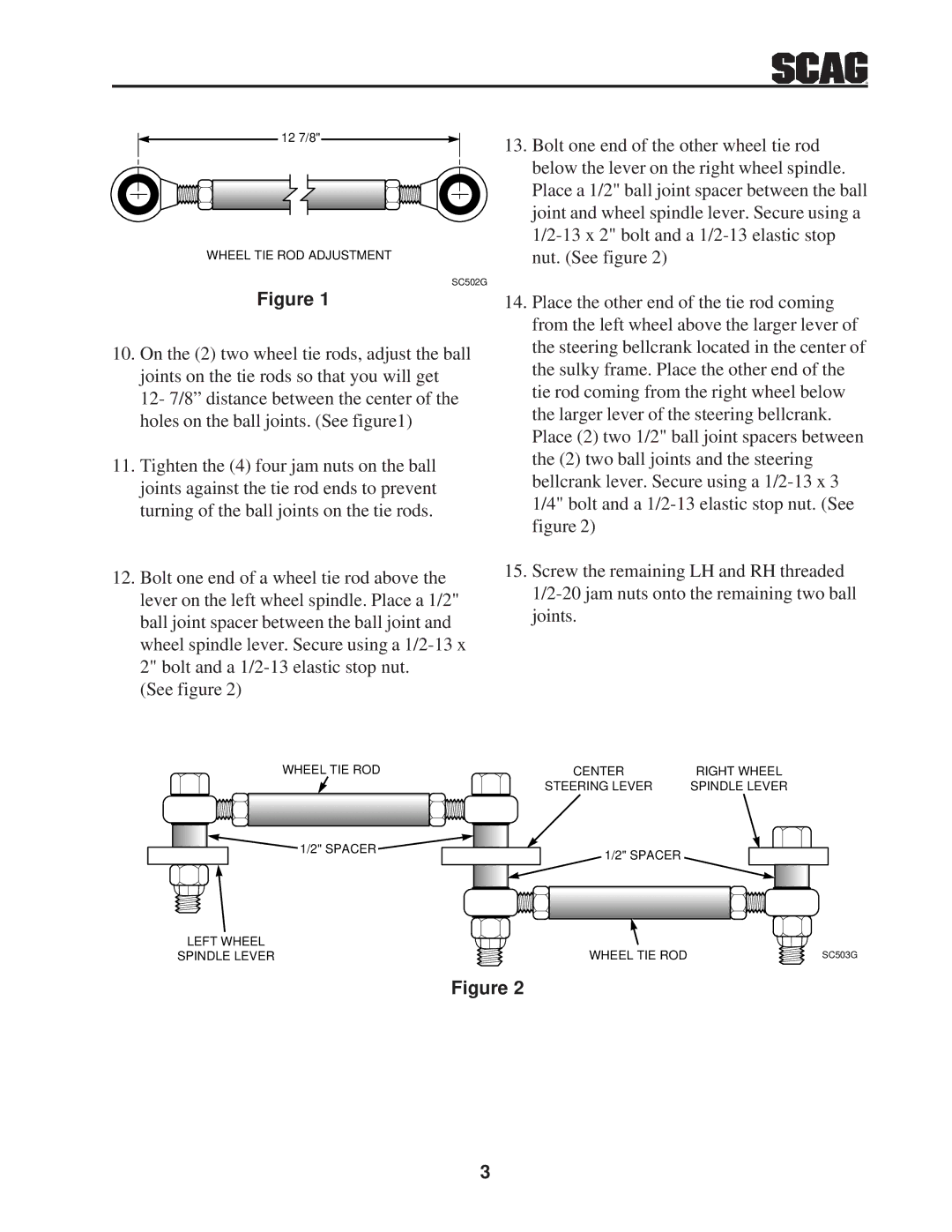

WHEEL TIE ROD ADJUSTMENT

SC502G

13.Bolt one end of the other wheel tie rod below the lever on the right wheel spindle. Place a 1/2" ball joint spacer between the ball joint and wheel spindle lever. Secure using a

Figure 1

10.On the (2) two wheel tie rods, adjust the ball joints on the tie rods so that you will get

12- 7/8” distance between the center of the holes on the ball joints. (See figure1)

11.Tighten the (4) four jam nuts on the ball joints against the tie rod ends to prevent turning of the ball joints on the tie rods.

12.Bolt one end of a wheel tie rod above the lever on the left wheel spindle. Place a 1/2" ball joint spacer between the ball joint and wheel spindle lever. Secure using a

(See figure 2)

14.Place the other end of the tie rod coming from the left wheel above the larger lever of the steering bellcrank located in the center of the sulky frame. Place the other end of the tie rod coming from the right wheel below the larger lever of the steering bellcrank. Place (2) two 1/2" ball joint spacers between the (2) two ball joints and the steering bellcrank lever. Secure using a

15.Screw the remaining LH and RH threaded

WHEEL TIE ROD | CENTER | RIGHT WHEEL |

| STEERING LEVER | SPINDLE LEVER |

1/2" SPACER | 1/2" SPACER |

|

|

|

LEFT WHEEL | WHEEL TIE ROD |

|

SPINDLE LEVER | SC503G |

Figure 2

3