Section 7

7.5 ENGINE FUEL SYSTEM

To avoid injury from burns, allow the mower to cool before removing the fuel tank cap and refueling.

FUEL

FILTER

HOSE

CLAMPS

STT99FF

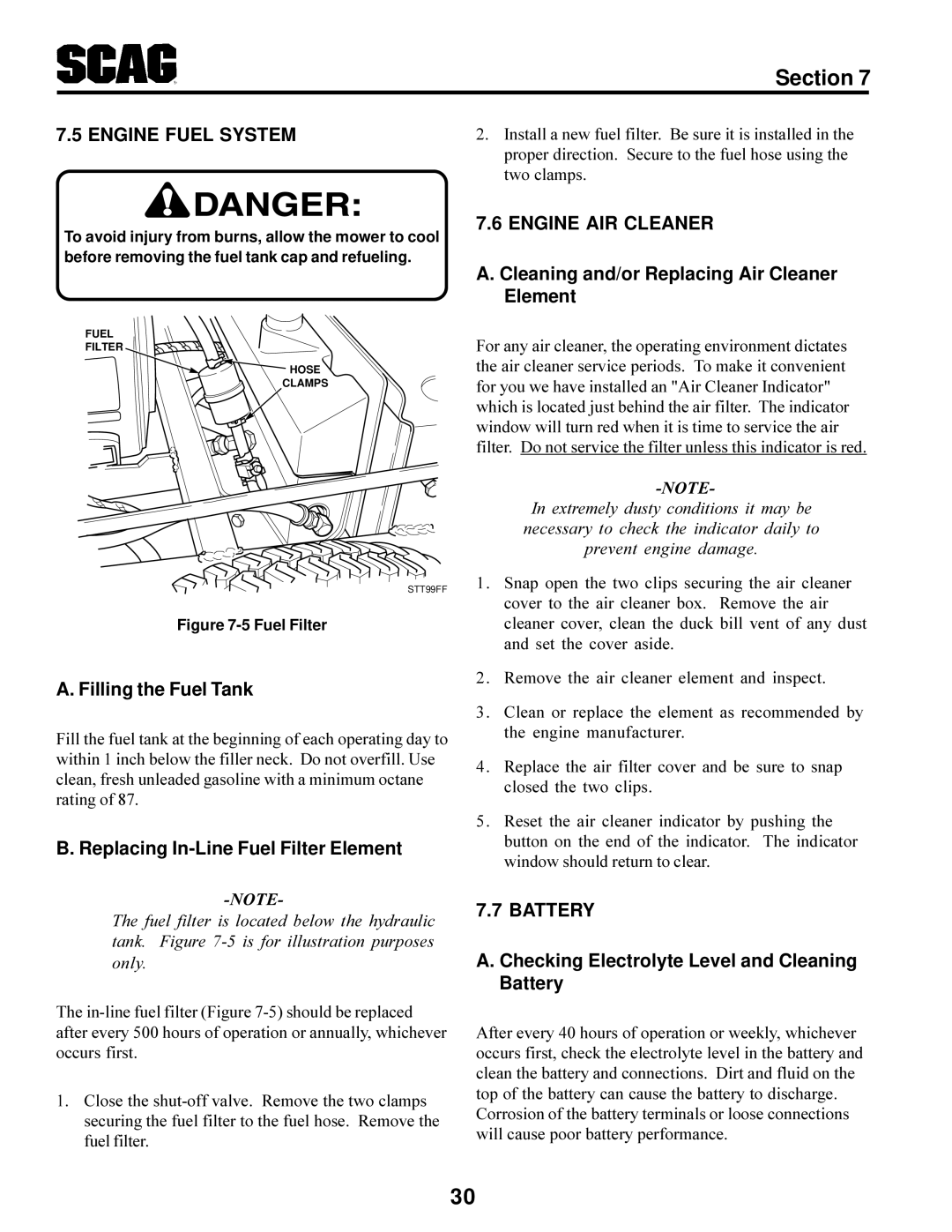

Figure 7-5 Fuel Filter

A. Filling the Fuel Tank

Fill the fuel tank at the beginning of each operating day to within 1 inch below the filler neck. Do not overfill. Use clean, fresh unleaded gasoline with a minimum octane rating of 87.

B. Replacing In-Line Fuel Filter Element

The fuel filter is located below the hydraulic tank. Figure

The

1.Close the

2.Install a new fuel filter. Be sure it is installed in the proper direction. Secure to the fuel hose using the two clamps.

7.6 ENGINE AIR CLEANER

A. Cleaning and/or Replacing Air Cleaner Element

For any air cleaner, the operating environment dictates the air cleaner service periods. To make it convenient for you we have installed an "Air Cleaner Indicator" which is located just behind the air filter. The indicator window will turn red when it is time to service the air filter. Do not service the filter unless this indicator is red.

In extremely dusty conditions it may be necessary to check the indicator daily to prevent engine damage.

1.Snap open the two clips securing the air cleaner cover to the air cleaner box. Remove the air cleaner cover, clean the duck bill vent of any dust and set the cover aside.

2.Remove the air cleaner element and inspect.

3.Clean or replace the element as recommended by the engine manufacturer.

4.Replace the air filter cover and be sure to snap closed the two clips.

5.Reset the air cleaner indicator by pushing the button on the end of the indicator. The indicator window should return to clear.

7.7 BATTERY

A. Checking Electrolyte Level and Cleaning Battery

After every 40 hours of operation or weekly, whichever occurs first, check the electrolyte level in the battery and clean the battery and connections. Dirt and fluid on the top of the battery can cause the battery to discharge.

Corrosion of the battery terminals or loose connections will cause poor battery performance.

30